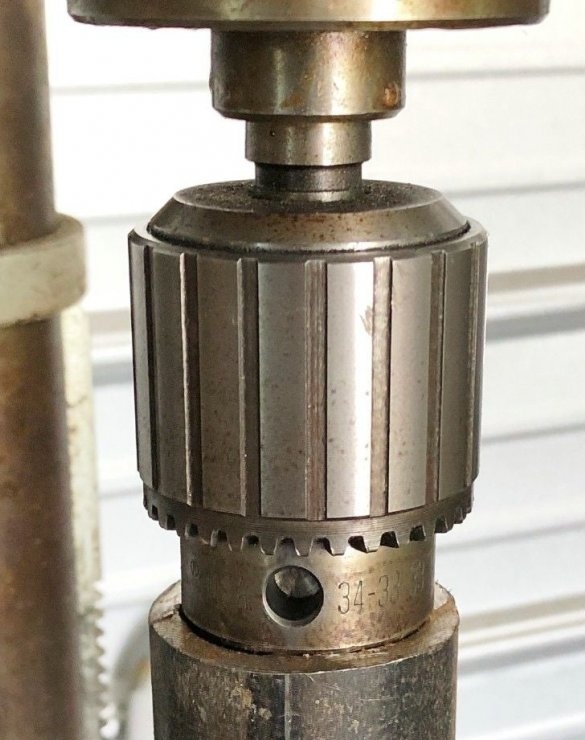

I must make a reservation right away that it will be necessary to cut the thread manually, and the drilling machine here is used for alignment. Without a machine, you can also thread, but, especially in thin metal, the tap can “fork” and the thread will go wrong. The principle of operation is simple. The tap is clamped into the cartridge, the part with the hole is located exactly under it. Then you need to press the tap to the part and turn the cartridge.

Tools and materials:

For adapter

-1 1/2 inch metal pipe;

-1/2 inch metal tube;

-Bolt;

For adapter

-1/2 inch steel bar;

Tool

-Band-saw;

-Beard;

-Drill;

-Drill;

-Tap;

-Lathe;

-Calipers;

-Spring clamp;

-Hacksaw;

-File;

-Triangular file;

-Welding machine;

Step One: Pipe Cutting

The 1 1/2 inch pipe has an inner diameter very close to the diameter of the bottom of the drill chuck. The master cuts off 2 centimeters of pipe.

Step Two: Turning

Next, you need to grind the inside of the pipe so that it is put on the bottom of the cartridge. In the absence of a lathe, this can be done using a file.

Step Three: Hole

The master drills a hole in the side of the ring and cuts the thread.

Step Four: Pen

The master made a pen from a tube. I welded a bolt head to the tube.

Now you need to install the tap in the cartridge, and clamp the part in a vice under the tap. The cartridge rotates with the handle. After each revolution, the clamp loosens and the handle moves to its original position.

Step Five: Adapter

Now you need to make an adapter. The fact is that the cartridge has three cams and a tap on the end of four faces. As a result of this, a skew occurs.

To make the adapter, the master cuts off about three centimeters of a metal rod.

Installs the adapter in the cartridge and marks the location of the cams with a marker.

Stitches the rod over the marks.

Precisely in the center drills a through hole in the adapter.

Next, you need to make the hole square with the file, focusing on the shank of the tap.

Now you need to install the tap in the adapter, clamp the adapter into the drill chuck, and you can cut the thread.

Such an adapter has a significant drawback, if the tap shank is of a different size, then it can no longer be installed in the adapter.