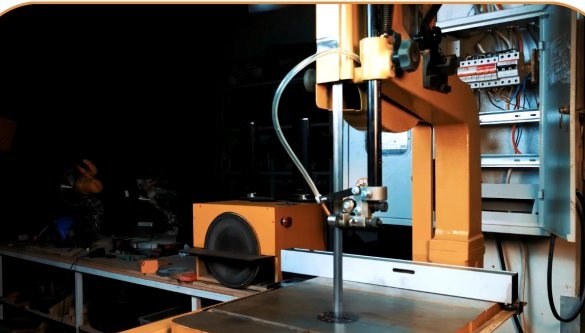

One of the universal and necessary machines for the workshop is a band saw.

In this article, Dania, the author of YouTube channel "SuperCrastan", will tell you how to expand its capabilities by modifying the working canvas.

Materials

- Old band saw blade

- Rubber, paper, cardboard

- Wood screws.

Instruments, used by the author.

—

—

- Grindstone

—

- Vacuum cleaner

- Screwdriver, knife, ruler, goniometer, pencil.

Manufacturing process.

So, the author was puzzled by the ways of cutting various types of rubber.

For straight cuts of sheet rubber, an ordinary knife is also suitable, but with its help it is difficult to cut curly blanks.

A knife with a disk blade is better suited for this.

But it also has its limitations, this is also due to the working width of the blade, which limits the minimum radius of the cut.

However, the master has at his disposal a band saw machine. He decides to replace the canvas in it, and imprison it in an “endless knife”. Such a machine has two pulleys leading in the lower part and a driven one in the upper one.

A standard canvas easily cuts sheet plywood, and allows you to dissolve even a large wooden blank on thin planks or panels.

When removing the canvas from the pulleys, you need to be very careful, you can get it in the face.

For folding the canvas, this is the technique used. The canvas is divided into three conventional segments. One is pressed to the floor with the foot, and the other two are folded like this.

Now the author sets the worn cloth in the machine.

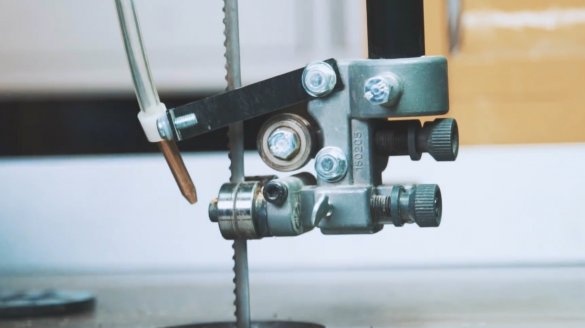

In addition to aligning it on the pulleys, it is necessary to adjust the pinch bearings. The first group is above the saw table, and the second is below it. These fixtures Do not allow the canvas to bend during curly work.

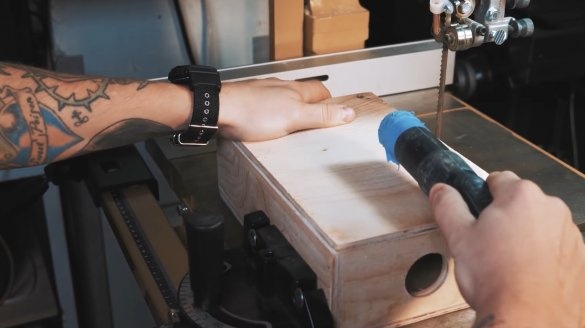

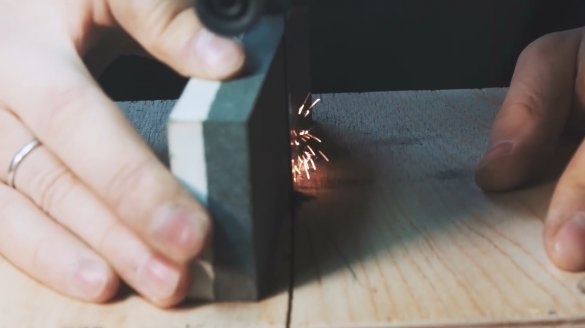

Since the master plans to sharpen the canvas, cutting off the teeth and then the edges, he wants to avoid the abrasive material getting inside the machine mechanisms.To do this, he made a simple box of plywood, and drilled a hole for a vacuum cleaner hose in it. Then he made a cut in this box.

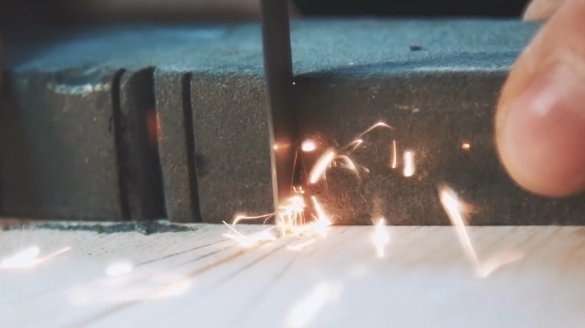

The saw is turned on and the teeth are removed using a grindstone.

The author also made marks on the surface of the box, which will first help to make descents of 5 degrees on each side of the canvas, and then the main sharpening of the blade of 15 degrees on both sides.

A piece of injection-molded silicone can be mastered by the machine in a few seconds.

But the canvas could not stand it and burst. Probably the author pulled it too hard, or he did not have enough width. He took a new canvas, and repeated the whole process again.

This canvas is wider, and it was decided to conduct the first tests with cardboard and paper.

The machine copes with a piece of silicone and sheet rubber very well, but it will be necessary to replace the protective tab, the blade strives to tighten the sheet rubber in its slots.

But with a thick piece of rubber, nothing happened. The blade was simply stuck in it. The author even tried to cut it without using emphasis, but to no avail. It may make sense to cover the side surfaces of the web with something like Teflon to reduce friction.

With thin sheet rubber, even curly cuts are excellent.

What else can be cut? Well, for example, shawarma, or a cupcake.

A roll of paper towels can also be divided into two.

It is also convenient to cut the foamed polyurethane into strips of the required width. The cut is very smooth and without burrs.

In the same way, it is possible to cut boards made of polystyrene foam and other heaters.

And so you can make elegant shorts out of jeans.

Having added the remainder of the jeans in 12 layers, the saw was waiting for another test, with which she successfully coped. Even cut a brass button in two.

I thank the author for the simple but useful idea to expand the capabilities of the band saw!

All good mood, good luck, and interesting ideas!

Author video can be found here.