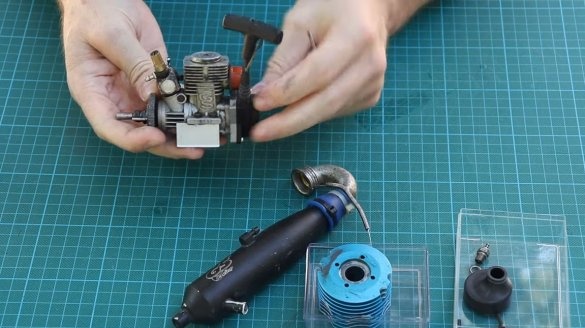

I welcome fans to craft, I propose to consider an autonomous power source from which you can charge a mobile phone, laptop and other equipment, and you can also organize a lighting system using LEDs in the event of a blackout. The author used for his needs two small engines, which turned out to be a generator. A 795 motor was used as an electric generator, 555 or 775 would also be suitable. As for ICE, the author used a small nitroengine, which is usually used on models of boats, airplanes or on typewriters on a control panel. Such a motor consumes little fuel, however, it needs a special fuel with oil for two-stroke engines. Depending on the speed, the generator generates from 0 to more than 20 volts. If you need one homemade and you are interested in the project, I propose to get acquainted with it in more detail!

Materials and tools used by the author:

Material List:

- ;

- or similar direct current;

- and brass coupling;

- fiberboard or similar base material;

- pieces of boards or bars;

- ;

- a metal clamp from a steel plate;

- self-tapping screws.

Tool List:

- a hacksaw;

- screwdriver;

- soldering iron.

Generator manufacturing process:

Step one. Engine cleaning

The author used an old motor that had not worked for a long time. As a result, the engine was disassembled and well cleaned, the author used the WD-40. As soon as all the details sparkled, the motor can be assembled back and made the first start.

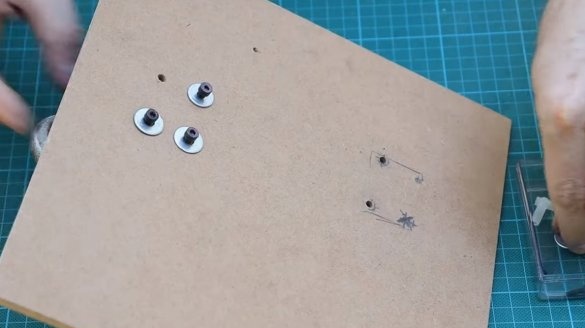

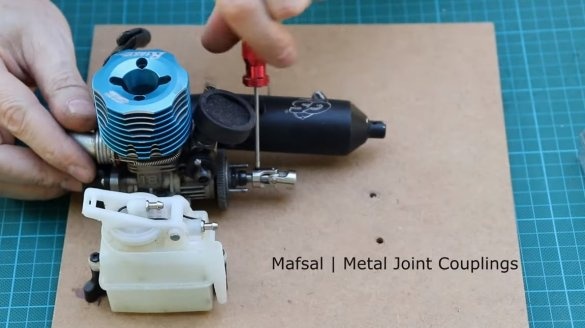

Step Two Nitromotor installation

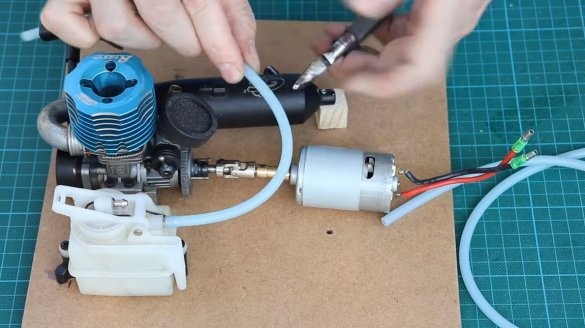

We install the nitro engine on the base, it can be a thick fiberboard, plywood or the like. We securely fasten the engine with screws, and also install a fuel tank nearby. The motor also has a silencer, it must also be screwed to the base through a block or piece of board.

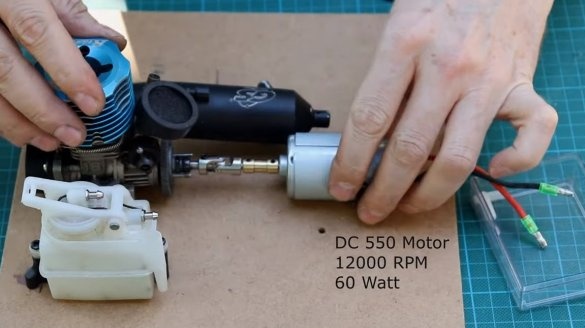

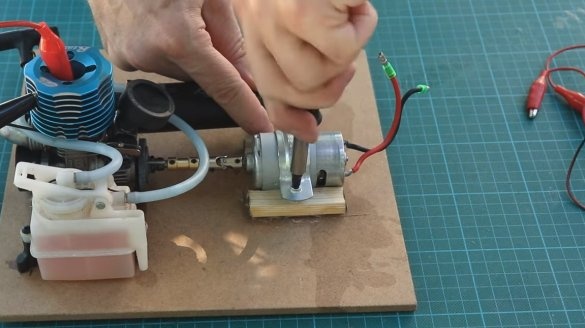

Step Three Generator connection

Opposite the shaft of the nitroengine, we install the shaft of our electric motor-generator, it is better to make the axes as level as possible. The author connected the motor shafts through the crosspiece from the universal joint transmission.Of course, such a node will transmit torque in jerks and it is better to use a full-fledged cardan. If there is no cardan, you can connect the shafts with a piece of a strong hose and clamps.

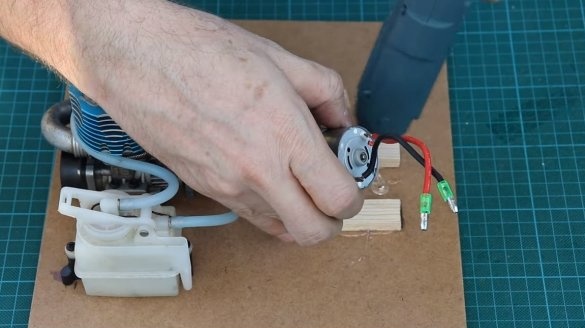

For the generator, we glue the stops from the blocks and we attract it well to the base with screws or self-tapping screws. The author first used hot glue, as a result of which the motor immediately flew off. The use of hot glue in this case is not an option, because the generator under load will generate a lot of heat.

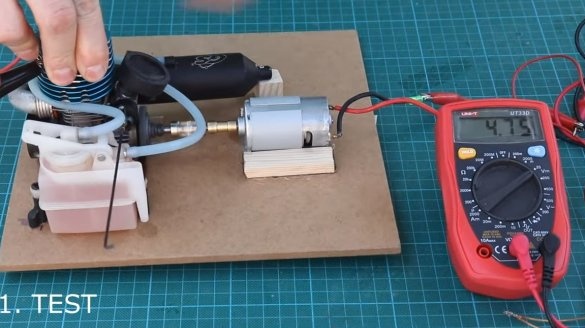

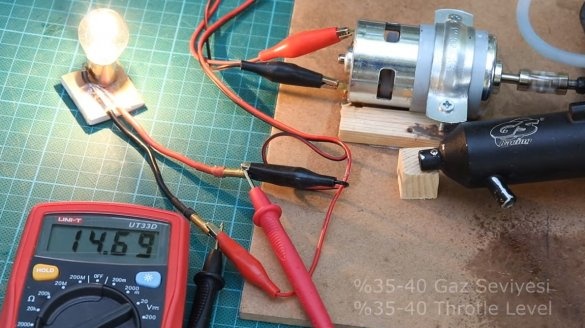

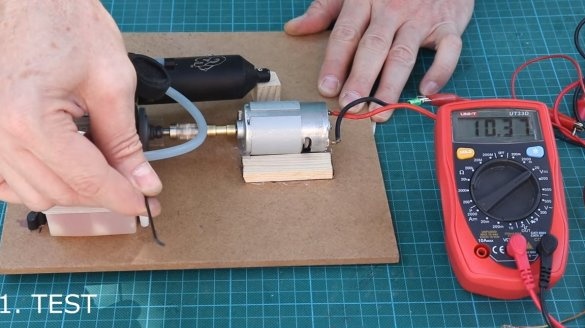

Step Four Test

As tests, the author lit a 12V car incandescent lamp. By increasing the speed, the burnout of the bulb and a voltage of more than 20V were achieved.

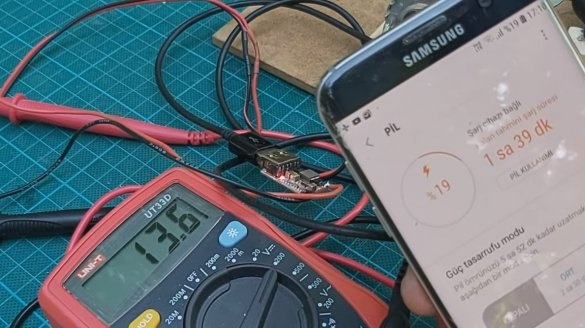

Further, the author connected a step-down converter to the contact outputs, which is able to reduce the input voltage of 7-24V to 5V with a current of 3A. From this converter, the author charges the mobile phone.

Of course, the nitro engine speed will need to be adjusted so that the generator produces the desired current at minimum speed. Do not forget that the generator produces a constant, but pulsating current, which must be smoothed by capacitors.

This is the end of the project, I hope you liked the project, and you found useful thoughts for yourself. Good luck and creative inspiration, if you decide to repeat this, do not forget to share your ideas and homemade things with us!