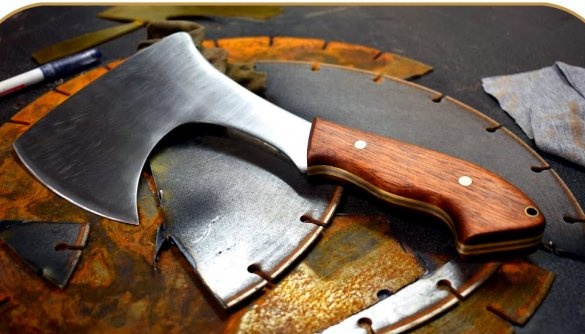

Many of you like various knives and hatchets. Especially when they are made of high quality, albeit from simple materials.

In this article, the author of the YouTube channel "Hassan Abu-Izmero" will tell you how he made just such an hatchet from an old saw blade.

Homemade is quite simple to manufacture, but will require the presence of some machines.

Materials

- Old saw blade

- Oak plank

- Sheet brass, bar, tube

- Machine oil

- Sandpaper

- masking tape

—

—

- Spray paint.

Instruments, used by the author.

—

—

- Cleaning and cutting discs

—

- Belt sander

- Grinder

—

- Vise, knife, pencil, marker, hammer.

Manufacturing process.

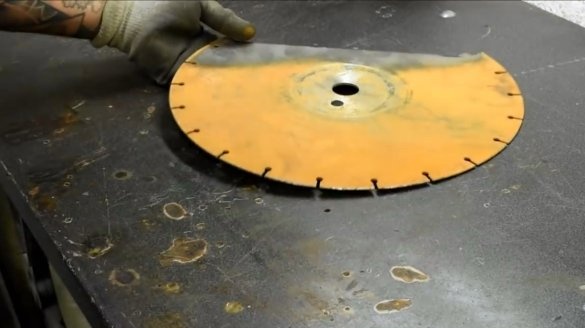

So, the master found an old saw blade. It is heavily rusted and must be cleaned with an orbital sander.

After that, the author cut out a paper template, and transferred its contours to the surface of the disc, simply applying a layer of spray paint. Then roughly cut the workpiece with a grinder.

Clutching it in a vise, leveled all faces with a cleanup disk.

On a belt grinding machine, it preliminarily forms descents.

Heats the blade with a gas burner and quenches in engine oil.

To facilitate the processing of steel, he needs to release the metal of the handle.

Winding sandpaper on a wooden block, cleans the surface of the workpiece.

Using masking tape, covers part of the workpiece.

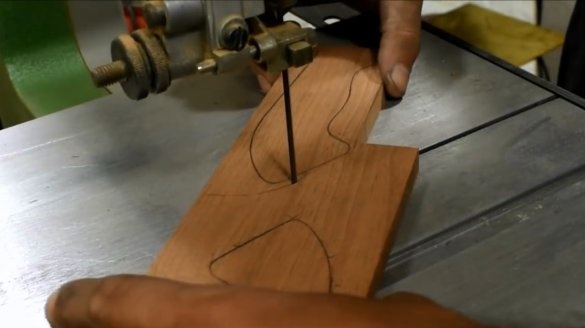

It transfers the contours of the handle to the oak board and brass sheet. Such blanks need two pairs.

Cut wooden parts on a band saw, while leaving a small margin around the contour.

Lubricates the cut points with machine oil, and cuts out two plates.

In the handle, drills holes for rivets and pendants.

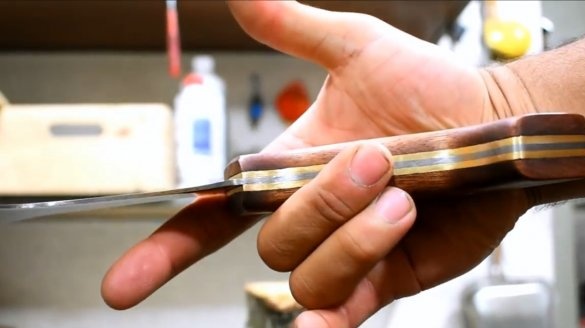

Pre-inserts the pins, collecting the handle. Now cuts the contours more accurately.

Grinds the edges of the handle.

Mixes components of acrylic glue, and sticks together the handle.Clogs two pins from a brass bar, and clogs a brass tube into the outer hole. Then clamps the product in clamps, and leaves to polymerize.

While the handle looks like this.

Now it can be polished, how brass inserts look beautiful!

To round the handle, the master cut a strip of sandpaper and processed it manually.

Now you can sharpen the blade completely.

It remains only to soak the handle with linseed oil to protect it from moisture. By the way, there is another good prescription for wood impregnation, it is described in this article.

Here is a beautiful handle turned out. Brass inserts are just great.

Actually the appearance of the finished product in various angles. Unfortunately, the author did not show how the design is balanced.

I thank the author for a simple but very beautiful idea for making a homemade hatchet!

All good mood, good luck, and interesting ideas!

Author video can be found here.