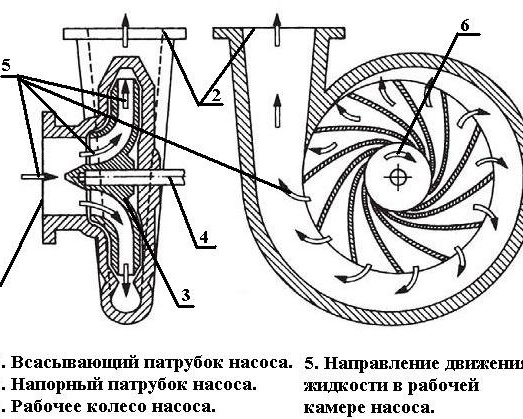

The blades of a centrifugal pump untwist water, as a result of which it moves from the center to the edges. In the center most often, there is an inlet pipe, and at the edge of the impeller there is an outlet.

The pump pumps water due to the speed of rotation of the water in the impeller, as I wrote above. That is, the incoming new water needs to be untwisted all over again and again, since it does not spin, it is a "standing mass", this causes a load on the motor!

That is, the slower the water enters the pump, the easier it is for him to work, since you need to spin a small mass! If the suction is completely closed, the impeller will work just like a solid rotor, it will not lose mass and, at the same time, kinetic energy.

And this is logical, the MORE water the pump pumps, the MORE it consumes current and the harder it is. Therefore, everything is actually the opposite of what the absolute majority thinks.

But if the motor is powerful, the example with suction shutoff is not correct (there will be cavitation), it is better to take the output shutoff as an example.

A submersible pump with a centrifugal impeller will work similarly. But! If there is a "propeller" or piston, then of course, with a decrease in performance, current consumption will increase and the load will increase.

Or I'm wrong?)