Both manufacturers and individual craftsmen have created and are creating various types of vise, clips and clamps.

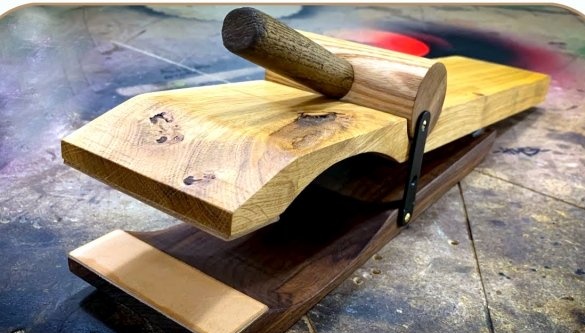

In this article, the author of the YouTube channel "Hassan Abu-Izmero", will tell you about the unusual quick-clip clip made of wood, which he made for his workshop.

This homemade product is quite simple to manufacture, and will not take you much time.

Materials

- Board made of hazel, mahogany

- Steel strips with perforation

- Furniture hinge

- Sheet leather

- spring

- PVA glue

- Sandpaper

- universal glue

-, wax

- Spray paint

- Wood screws.

Instruments, used by the author.

—

- Miter saw

- Belt sander

-, cutting disc

—

- Anvil, hammer, vise

—

- Lathe, chisels, cutters

- Square, ruler, pencil.

Manufacturing process.

So, the author begins with the manufacture of the pressure cylinder. To do this, he cuts a rectangular blank from the hazel massif.

At its ends it finds centers, and processes it on a lathe. You can do without a lathe, finding a wooden cylinder of a suitable size.

The ends of the cylinder are trimmed, and a handle of the required length is made of the handle.

Now, the author notes a recess for the cylinder on the outside of one sponge, and marks the radius on the inside.

Cut the grooves in the jaws for the cylinder, and on their inside.

Levels two steel plates and drills holes for mounting screws. The workpiece is trimmed and its edges are rounded off on a belt sander.

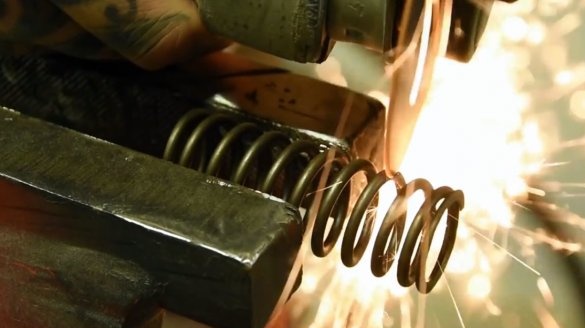

Further, the author adjusts the spring to the required length.

On both blanks marks the centers of the grooves for the spring, and drills them with a Forstner drill.

It also drills a hole for the handle in the pressure cylinder and glues it into it.

All surfaces of the workpieces are ground first with a machine, and then manually.

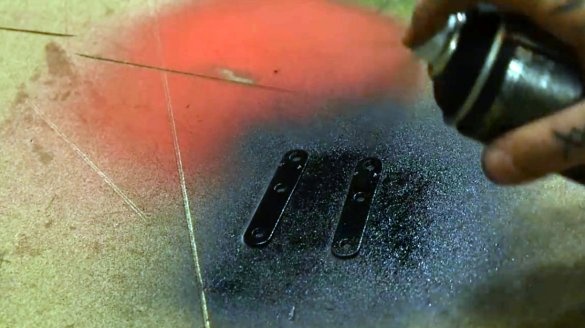

Steel plates are spray painted.

Now, two rectangles are cut out of the sheet of light skin to create soft clip lips.

Applies universal glue to the workpieces, glues them into place, and presses them with a load.

Aligns the parts of the clip with respect to each other, and fastens a furniture loop to the first half.

In the second half, pilot holes are also marked and drilled. Then the loop is screwed with short screws.

All surfaces fixtures treated with wood impregnation, and the sponges themselves are waxed.

Now the clamping cylinder is installed in the groove, and steel plates are screwed to it. The second part is screwed to the other half of the clip.

That's all, you can fix even soft materials in this unusual device. This clip can be fixed on the workbench in several positions with clamps, or simply screwed onto it.

I thank the author for a simple but useful quick-release tool for the workshop!

All good mood, good luck, and interesting ideas!

Author video can be found here.