As you all know, there are quite a few varieties of clamps.

In this article, the author of the YouTube channel "Ohyo56", will tell you about the method of manufacturing one of them. Namely, a lever clamp for a workbench.

Materials

- Cherry boards, hazel

- Impregnation for wood

- Sandpaper

- PVA glue

- Screws, washers, nuts

- Rubber furniture leg

- Contact adhesive.

Instruments, used by the author.

- A circular saw

—

- Drilling machine

—

—

- Drum grinding nozzle

- Orbital sander

—

—

- Vise, rasp, awl, mallet

- Pencil, tape measure, square, scissors.

Manufacturing process.

First of all, the master marks the boards of the required length, and cuts them.

One of the planks is slightly thicker than the other. The master aligned the emphasis on the first, thin board, and cut the second in a few strokes.

So, the dots are ready, you can cut out the template.

The template is glued to the blanks on contact adhesive, and left to dry.

The master does not have a band saw in the workshop, but there is such a home-made machine from an electric jigsaw with a canvas on a tree and thrust bearings. The author cuts blanks with his help.

It makes small radius cuts using a drilling machine and a Forstner drill.

The edges of the workpieces are machined with a rasp, then polished with a drum nozzle, and a disk machine.

With the help of an awl and a mallet, the marking of future holes is transferred.

The paper template is sanded with sandpaper.

The necessary holes are drilled in the parts.

Now you can glue individual parts of the structure, and fixes them with clamps.

After gluing, you will need to return to the grinding machine again.

Cleans the disk from dust, and polishes the parts.

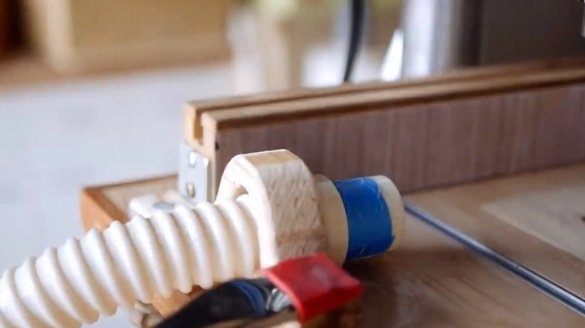

Installs a dust extraction system on a drilling machine table. Also puts an insert with a bearing, and fastens a drum grinding nozzle.

Drills a hole in the clamping head, and cuts an M8 thread in it.

M8 makes a presser foot out of a rubber furniture leg and screw.

The author did not like the base through which the fixing bolts were threaded, and he redid it. Now glued two halves of the structure.

He plans to fix this clamp through the bench table. In the meantime, to check the operation of the mechanism, he simply pressed it to the workbench. The lever snaps perfectly.

It remains to disassemble the entire structure, and cover it with wood impregnation. This can be done with linseed oil, wax, or eco-friendly impregnation of wax and rosehip oil, the manufacturing method of which was described inthis article. Such impregnation does not have such an unpleasant odor as linseed oil.

Here is a beautiful tool turned out by the master, it will be very nice to use it!

I thank the author for the simple but useful device for the workshop!

All good mood, good luck, and interesting ideas!

Author video can be found here.