This time we will consider how to assemble a structurally simple scooter based on a chainsaw. To make such a machine, you will need a lathe, well, or find a turner that will turn out the axis you need. The author used the motor for 58 cubes, he easily copes with the task. Note that the motors from chainsaws are poorly adapted to work under heavy loads, if the speed is low and the load is large, the motor will overheat, and the piston group will have higher loads. It is necessary to ensure that the motor does not overheat, but it is better to do additional cooling for it. The author made the frame from a piece of a square steel pipe, as well as parts from an old bicycle. If the project interests you, I propose to study it in more detail!

Materials and tools used by the author:

Material List:

- a rectangular steel pipe of suitable diameter;

- old bike;

- a chain drive from a motorcycle or the like;

- chainsaw;

- a piece of channel;

- Sheet steel;

- bolts and nuts;

- bearings and axis.

Tool List:

- lathe;

- welding machine;

- grinder;

- vise;

- Miter saw;

- drill;

- marker, tape measure.

Manufacturing process homemade:

Step one. Frame manufacturing

First of all, we will make a frame for a scooter. As a basis we use a piece of a rectangular pipe of large diameter, it can withstand heavy loads. The ends of the pipe are welded with sheet steel. We make the rear fork, for this you need a corner. As for the front, then the author simply welded the front of the frame from the bicycle. All welds should be very strong, for safety it is better to additionally strengthen all with steel plates.

Step Two Steering wheel

The steering shaft of a bicycle needs to be lengthened, for this the author adapted a piece of a round pipe of suitable diameter.

Step Three Wheels

We install wheels on the frame, they should be equipped with disc brakes, it is better if both wheels will brake. We need to install a driven sprocket on the rear wheel.To solve the problem, the author simply welded a motorcycle sprocket to the rear bicycle. The main thing is to do everything exactly. As for the carriage, it can be brewed, the scooter will already be equipped with a centrifugal clutch and will be able to move forward.

Step Four Motor bed and working axle

The engine, that is, the chainsaw, needs to be firmly fixed, as the basis the author used thick sheet steel. And so that the motor can be installed at a certain height, we simply weld a piece of the profile pipe perpendicularly to the frame. Please note that the higher the center of gravity, the lower the stability of the scooter.

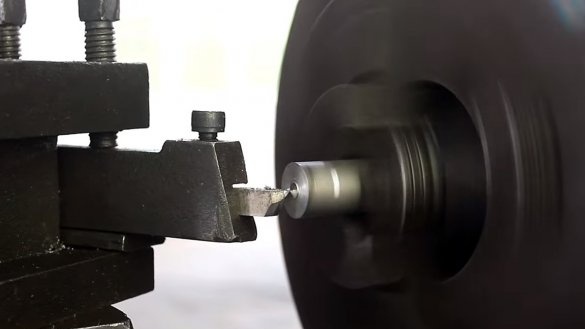

A working axis is also installed on the bed for the chainsaw, which transmits torque from the engine to the rear wheel. The author turned the axis himself on a lathe; for the axis, bearings in housings are needed. We weld an asterisk from a motorcycle to one side of the axis, it will transmit torque to the wheel. On the other side we weld a “plate” of centrifugal clutch from a chainsaw.

Step Five Assembly, painting and testing

We install the engine in its place, securely fasten it with screws to the bed. Install the axle, bearings and chain. Be sure to install the brake, the author only brakes the front wheel. In general, the weight of the scooter is large and even with sharp braking it should not tip over.

As for gas, we hold the cable from the brake handle of the bicycle and connect it to the saw throttle. The painted scooter looks quite decent, you can experience it. The author easily starts off and rides on his brainchild, the engine runs at low speeds. If the motor overheats, it will start to work worse, in this case it is impossible to gas, since the motor will jam. That's all, the project is completed, I hope you liked the homemade work, and you found useful thoughts for yourself. Good luck and creative inspiration, if you decide to repeat this, do not forget to share your ideas and homemade things with us!