Almost every one of you likes unusual items of design and everyday life.

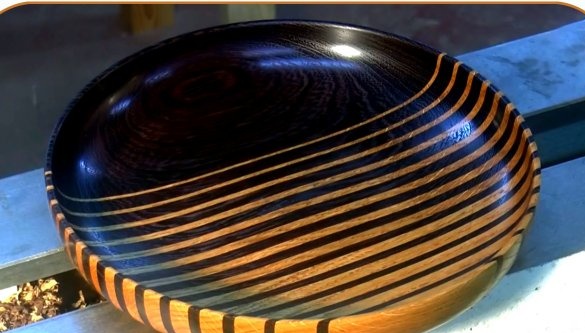

In this article, Maxim, the author of the YouTube channel “Maxim Kozlov”, will tell you about the original way of making plates from oak and wenge wood.

Materials

- Boards from oak and wenge wood

- PVA glue

- Sandpaper

- Tung oil, antique wax

- Wood screws.

Instruments, used by the author.

- Jointer, planer

- A circular saw

—

—

—

- Lathe

- Grinding machine

- Chisel, compass

- Roulette, ruler, pencil, roller, brush.

Manufacturing process.

First of all, the master processes two base surfaces on the boards using a jointer.

The remaining surfaces are processed by a surface gage.

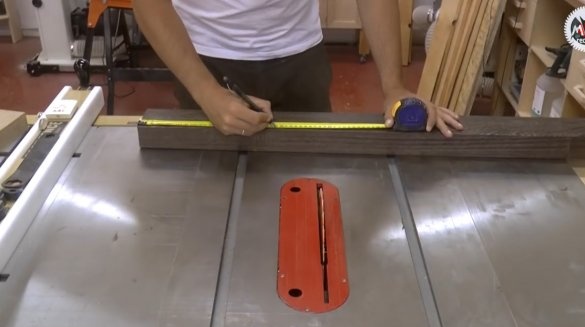

Now the boards are cut into blanks of the same length.

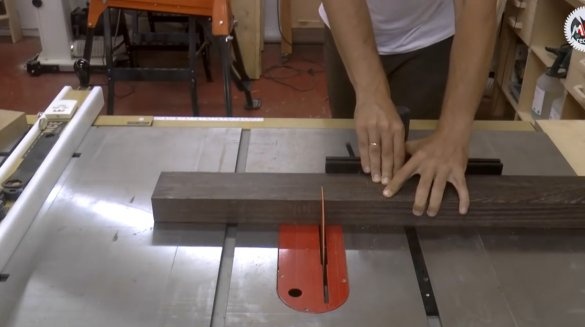

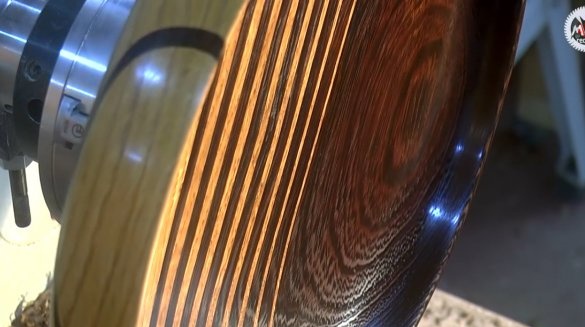

Maxim performs further work on dissolving the blanks on the plates with a band saw. Her blade “eats” three times less material than a circular saw blade. And wenge wood is very valuable and expensive. All plates will be of different thicknesses, repeating only in pairs.

Finally, the thinnest plate is cut out, and the master is ready for such a set.

Then, the surfaces of the pulp are polished on the machine.

So, everything is ready for gluing. The author applies glue to the workpieces, and evens it with a roller and brush.

Then he collects the shield, and pulls it with clamps.

After the glue dries, its remnants are removed with a chisel.

On the workpiece, the master finds the center, drills the pilot holes, and fastens the flange.

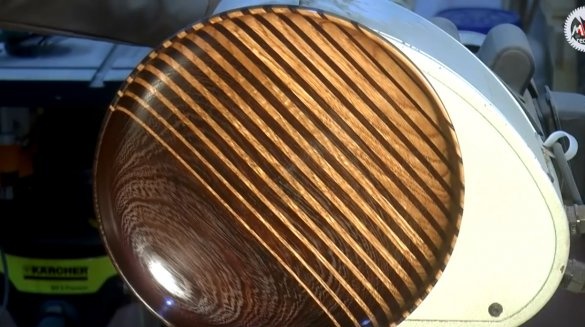

Excess material is cut on a band saw, they are useful for other projects. The workpiece is mounted on a lathe.

First, the master rounds the outer surface, levels the bottom, and begins to form lateral slopes.

At the bottom marks the edges of the future groove, and makes it.

The external surfaces of the plate are polished with sandpaper up to the 320th grain size. After sanding, the surface is ground with sawdust.

Treats surfaces with tung oil.

After the oil has been absorbed into the wood, it applies a layer of wax and polishes the surface with a rag.

Removes the flange from the workpiece, and changes the spindle on the machine.

Then it begins to grind the inside of the plate, trying to keep the thickness.

The tailstock pushes back and the remaining wood in the center is cut.

Now follows an exact fit in thickness, and grinding.

That's all, there remains the final oiling, waxing, and polishing.

What a beautiful texture for properly processed and high-quality wood material! These two types of wood contrast perfectly with each other.

I thank the author for the excellent performance of a plate of solid and valuable varieties of wood!

All good mood, good luck, and interesting ideas!

Author video can be found here.