I welcome all fans to craft, today we will consider how to expand the functionality of everyone's beloved grinder. The author decided to turn it into a renovator, or rather a vibration saw. With this tool, you can cut through various geometric shapes in wood and other materials. For example, you need to cut a square or a triangle, such a fixture can easily cope with the task. Main advantage homemade in that the design of the grinder does not change, homemade is just a nozzle. Everything works simply and reliably, using an eccentric from a bearing of a very simple design as the basis. If the project interests you, I propose to familiarize yourself with it in more detail!

Materials and tools used by the author:

Material List:

- suitable bearing for cam;

- washers, bolts, nuts;

- steel pipe;

- Sheet steel;

- an old hacksaw.

Tool List:

- grinder;

- welding machine;

- grinder;

- vernier caliper, marker;

- drilling machine;

- drill;

- a cylinder of paint.

Homemade manufacturing process:

Step one. Making an eccentric

First of all, we will make an eccentric, it is very simple to manufacture. We will need a radial ball bearing, the diameter of the inner hole should be slightly larger than the shaft diameter so that the bearing can be shifted to the side. To fix the desired position of the bearing, the author has machined a pin from a nail. Finally, the bearing is clamped with a nut and two washers. It is better to choose washers so that they do not clamp the bearing race, this will reduce friction.

Step Two Clamp and base

We make a clamp on which everything will rest, this is a kind of foundation. We are looking for a piece of steel pipe in diameter slightly larger than the part of the grinder on which the shield is placed. We cut the pipe, weld the nuts, the clamp is ready, it can be tightened with a screw or bolt. In the bolt, you can cut a slot for a flat screwdriver.

Next we need to cut out the base that will hold the knife. Here we need a piece of sheet steel, and it is better to choose a thicker steel.In a piece of steel, drill a hole for the bearing, and also weld two bolts that will serve as studs.

Step Three Knife

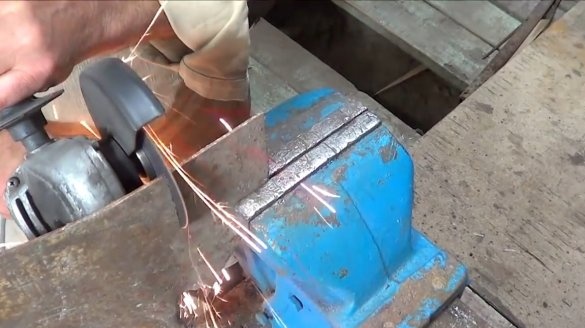

Next, we make a knife for a vibration saw, the author decided to use a piece of canvas from an old hacksaw on wood. Such steel will be strong, and the teeth of the saw will be able to hold the grinding for a long time. Cut off the desired piece and weld to it a steel plate with an oval hole, which will transmit movements from the eccentric to the knife.

At the end of the knife, the author cut the teeth with a drill, the effectiveness of the machine will depend on this.

Step Four Clamp reinforcement

In order for everything to be reliable, and to work safely homemade, you need to fix everything as securely as possible. The author decided to fix the clamp in two more places, and this will not be superfluous. Cut off two pieces of the plate, bend and drill holes. Additional fasteners will be screwed in the places where the front handle of the grinder is attached.

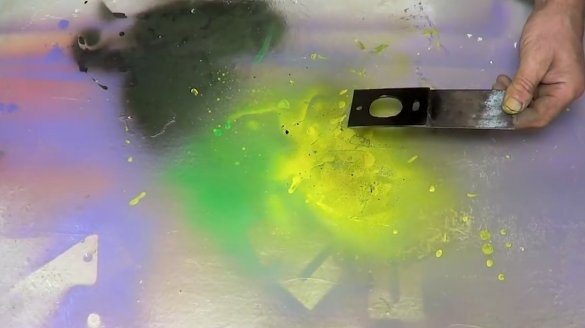

Step Five Painting and testing

We paint the details from the spray can. Thanks to the paint, the homemade product now looks wonderful, and will not rust.

We assemble the homemade product, first we fix the cam, and then the clamp, tighten all the bolts well so that nothing is unscrewed from the vibrations. You can install a knife, the author fixes it with washers and nuts. It is better to use nuts with a plastic retaining ring, such a nut will not loosen from vibrations, and it will also be possible to optimally tighten the nuts to reduce the clearance.

We read “our father” and start the grinder, everything works, you can experience it. The author easily cuts the board with a vibration saw. Of course, the main purpose of such a nozzle is to cut through

geometric figures in sheet material, the machine copes with this task.

To increase efficiency and durability, regularly lubricate the friction units of the nozzle. As for the vibrations from the eccentric, they, of course, will be. To remove vibrations, the eccentric must be double. Everything must be balanced.

The project is completed on this, I hope you liked the homemade work, and you found useful thoughts. Good luck and creative inspiration, if you decide to repeat this, do not forget to share your ideas and homemade things with us!