I welcome everyone, I offer you to consider an interesting emery, which you can make yourself from the old engine from the washer. Essence homemade in that it was possible to put the old erased discs from the grinder as a grinding wheel. Some masters accumulate heaps of such disks and feel sorry for throwing them away, as well as such “bits” can be found for free, if you know the place. The result is a good grinding wheel on which you can sharpen knives, axes, grind something, and so on. Of course, a powerful motor for such a machine is not needed, the author used an engine of only 180 watts. If the project interests you, I propose to study it in more detail!

Materials and tools used by the author:

Material List:

- a 180 W washing machine motor or the like;

- steel pipe, washers, bolt;

- Sheet steel;

- square profile pipe;

- corner;

- paint for metal;

- convenient switch.

Tool List:

- ;

- drill;

- welding machine;

- ;

- ;

- vise;

- file for metal.

Machine manufacturing process:

Step one. We work with the motor shaft

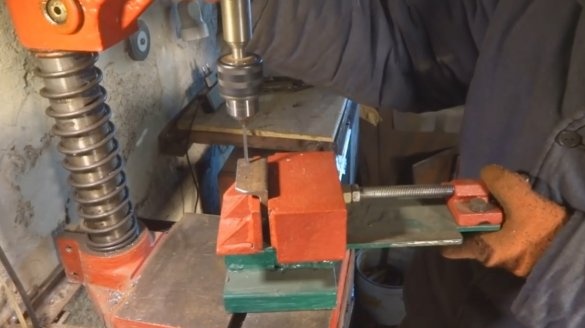

First of all, we need to modify the engine shaft, along it we need to drill a hole and cut the thread under the bolt inside.

Next, the shaft must be lengthened so that many disks from the grinder fit on it. As an extension cord, the author picked up a piece of steel pipe of such a diameter that disks were not worn with a small gap. The inner diameter was slightly larger than the diameter of the shaft. To solve the problem, the author made a sleeve of sheet steel of suitable thickness to center the pipe.

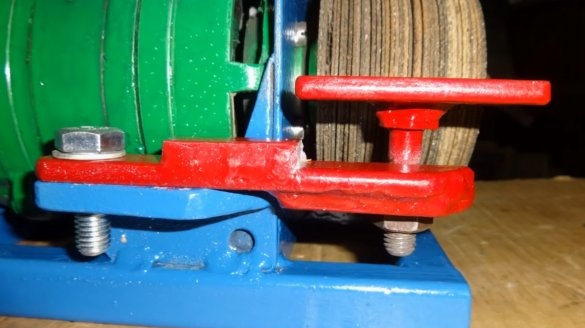

When all the parts are ready, you can collect emery from the drained disks. First, put a washer on the motor shaft, and then a piece of pipe. We put the right number of disks on the pipe, well, and then with the help of washers and a bolt we tighten everything well. After that, a homemade emery stone will be ready for us.

Step Two Frame for engine

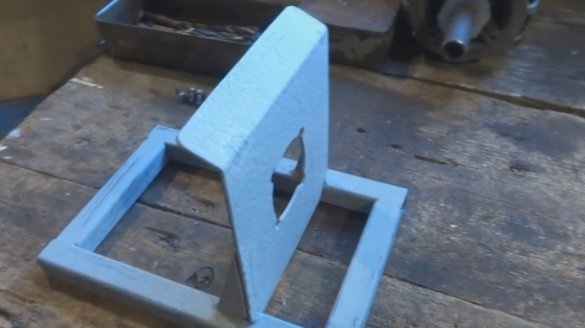

We assemble a simple frame for the engine, first the author made the fasteners for the motor from sheet steel.The motor can be secured with studs that tighten the halves of the case if there are no other mounting holes.

You also need to assemble a stable base for the machine, auto welded it from profile pipes. The motor fasteners are welded to the base and everything can be painted so that the homemade product does not rust.

Step Three Assembly

In the end, the author made a simple adjustable emphasis, which will make the work process much more convenient and safer. We install the motor, capacitors, and also put the switch in an accessible place. We isolate all the contacts well, and also use a cable with good insulation. Homemade ready, you can experience! To smooth the emery wheel, you can use a piece of grindstone or something similar.

The homemade product works fine, now you can not throw away the worn-out disks, they can all be drained to the end. Also, on this machine, if you wish, you can put classic grindstones. The project is completed on this, I hope you liked the homemade work, and you found useful thoughts. Good luck and creative inspiration, if you decide to repeat this, do not forget to share your ideas and homemade things with us!