A watch with a dial made using the same technology as a printed circuit board can be a great gift for a geek. And how to make such a dial and set it in the watch instead of the standard one, says the author of Instructableses under the nickname Sverd Industries. As a basis, he takes a serial watch:

As you can see, this is a watch with a spring drive and automatic winding. Not the best choice for remaking in home conditions. It is undesirable to violate the tightness of the case of such watches on their own, it happens that a few days after such an intervention they stop from dust. It is better to take a quartz watch, which is almost insensitive to dust. They can be opened, for example, to change the battery, in any room, and if at the same time nothing is broken in them, then they will continue to work normally.

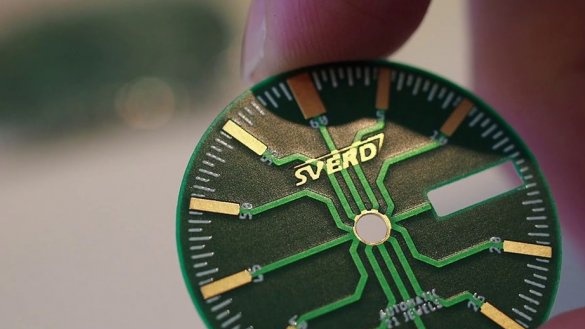

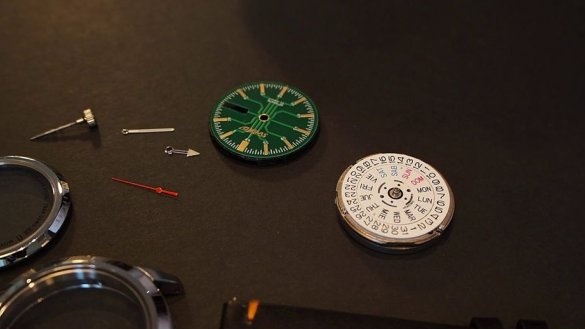

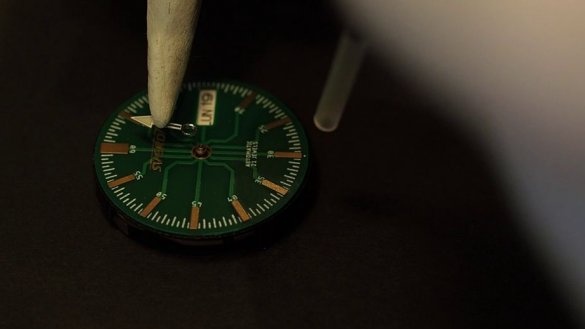

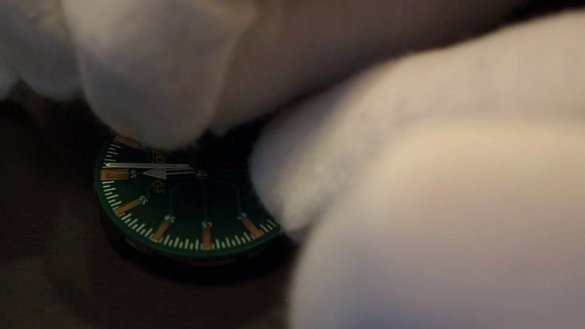

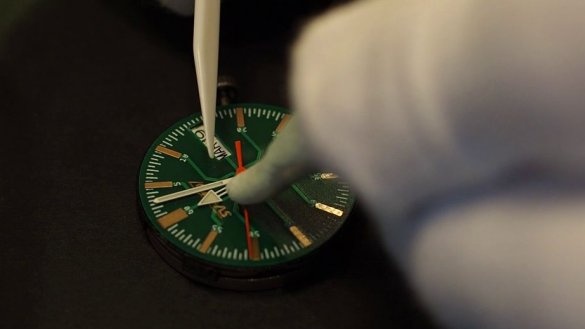

This is how the circuit board looks separately, before it is installed in the watch:

But we will return at a time when he is not ready yet. The master begins the alteration by removing the bracelet from the watch. Well, almost everyone knows how to remove, install, change the number of links in them; watchmakers rarely turn to watchmakers for such a service.

The watch case back can be mounted on a latch or on a thread. The first method is usually used in quartz watches, in this case, somewhere around the perimeter of the lid there is a protrusion for prying off with a screwdriver. The second method is more often used in watches with a spring drive like those shown here. In this case, a special key is needed to remove the cover. This is a pretty hot commodity in Chinese online stores. The master acquires such a key and removes the cover from the watch. Fearing to scratch the cover, he pre-seals it with electrical tape. After loosening the threaded connection, he further unscrews the lid with his palm.

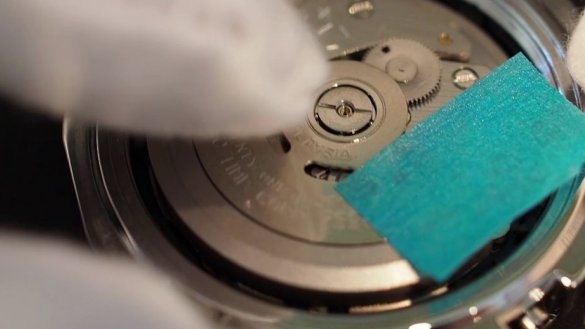

The master puts on cotton gloves, and then pushes the crown into a position in which its rotation does not lead to the movement of the hands. Presses a toothpick on the spring-loaded lever that holds the crown of the crown, and pulls it along with the shaft.

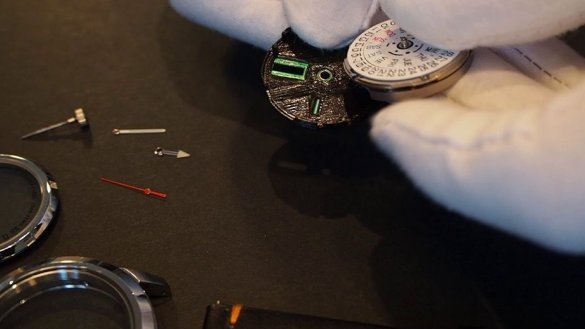

The master fixes the self-winding eccentric with adhesive tape so that it does not move, and removes the mechanism from the watch case:

Before removing the hands, the master returns the crown with the shaft to the extracted mechanism, sets the time to 12:00, places a piece of the package between the hands and the dial (suddenly he will someday decide to return the old dial to its place, so it’s important not to scratch it), and remove the hands with the intended for this special tool.

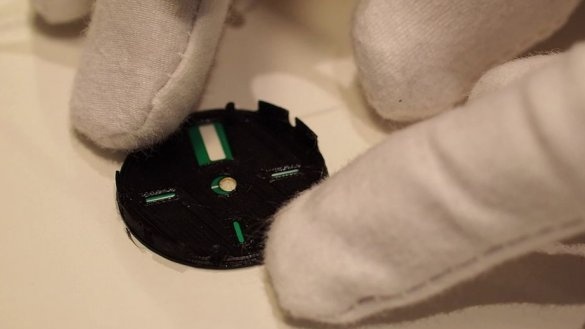

The master removes the dial, held on two pins, trying not to bend them. You can see discs with numbers and names of the days of the week in English and Italian.

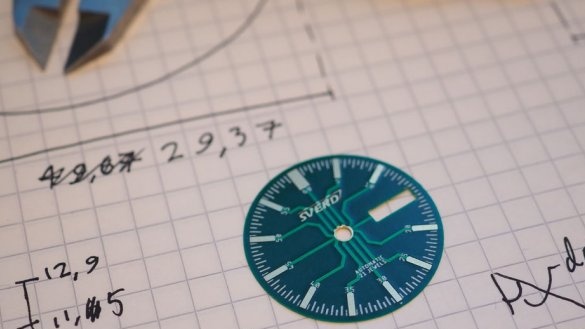

Now the mechanism must be set aside under the dust cap. To determine the position of the divisions on the new dial, the master prepares the theoretical base, and then draws up on its basis table (after downloading, rename the file, changing the extension unknown to xls).

The wizard will design the printed circuit board, which will be the new dial, in Autodesk Fusion 360 and upload the result here. He orders a board from PCBWay, another manufacturer suitable for making a round board with holes is also suitable. If you wish, you can even get confused on LUT, and then work yourself with very small needle files ...

Metal a bracelet the master replaces the watch with a leather strap, which exposes it to simple modding:

Repaints the second hand in the same style as the redesigned new strap:

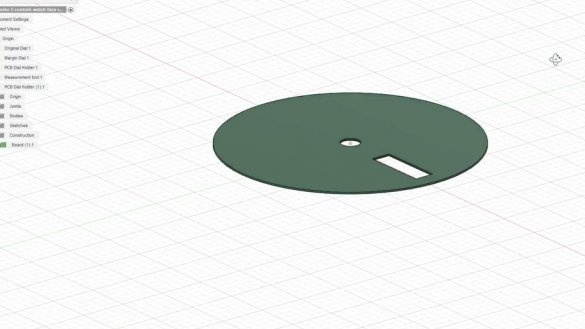

Designs a new mechanism and dial holder, uploads a file here and displays on a 3D printer:

A strip is provided on the back of the dial, and recesses are provided on the holder. Combining them, the master glues these details with each other.

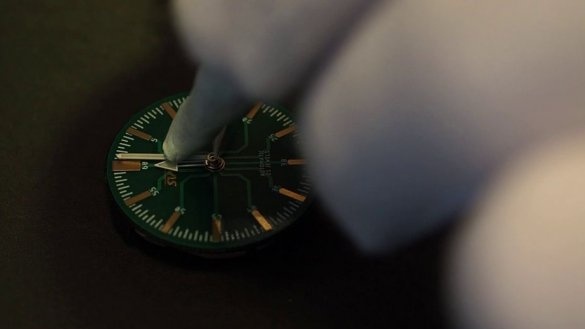

The master takes the mechanism, combines the window in the dial with the visible date, and then the pins for the old dial with the holes in the new holder, then connects the mechanism to the holder.

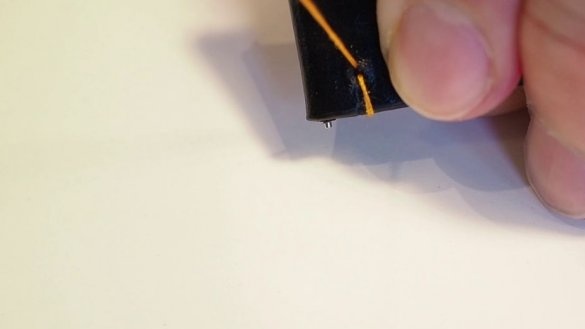

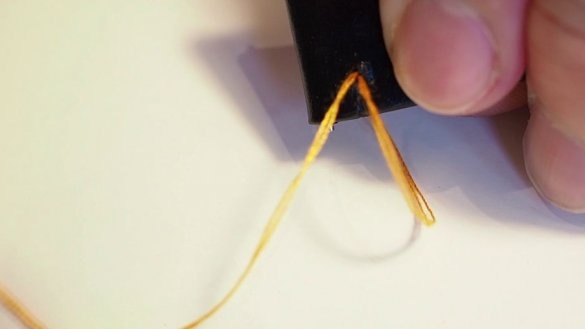

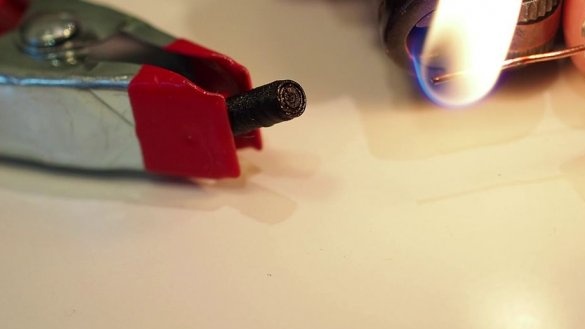

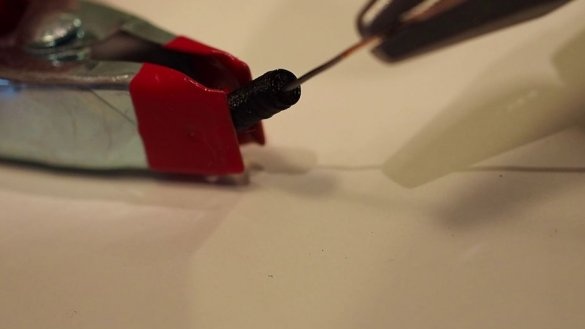

The wizard returns the arrows to their places. The hourly - with a ballpoint pen, the minute - a cylinder printed on a 3D printer, in the end of which a hole was made with a heated wire, the second - just put on the shaft, presses and glues a tiny drop of glue from a plastic stick. Then he looks at the result from the side through a macro lens.

After thorough dust blowing with a small compressor, the master installs the mechanism in the watch case, and then returns the crown to its place:

Screws the back cover with the same tool that I previously removed it, again using electrical tape, so as not to scratch the cover. It is important to wrap it tight, without this, the water resistance of the watch will be impaired.

Finally, the master installs a strap on the watch - a new one, and also a redone one:

All is ready. True, the files laid out by the master are suitable for the manufacture of parts for remaking watches of a certain brand - Seiko 5 SNKK27. But they can be modified for any other watch.

And if you are not ready to work with such tiny details, you can practice ... no, not on the kote, but on the alarm clock. After all, you can also make a dial for it using the same technology as a printed circuit board.