Surely almost every one of you is faced with the need to process small steel workpieces, and knows that even simple grinding of small parts can cause inconvenience.

In this article, the author of the YouTube channel “TOKARKA” will tell you how he made a special magnetic plate, with which this process will be much simpler, easier, and most importantly safer.

Materials

- Aluminum block

— Neodymium magnets

— Two-component acrylic adhesive

- Sheet stainless steel

- Brass screws M2

- Machine oil

Instruments, used by the author.

- Hacksaw

- Milling machine

— Tap

— Dremel

— Screwdrivermetal drills

- Automatic core

— Construction hair dryer

- Vise, vernier caliper, file, screwdriver.

Manufacturing process.

So, such a large aluminum block is suitable as a case. It has excellent thermal conductivity and will protect the magnets from overheating. The wooden case is not suitable for this homemade product.

Having fixed the block in a vice, the master cuts off a suitable workpiece from it.

The surface of the block is leveled on the milling machine, although this can be done with a regular file.

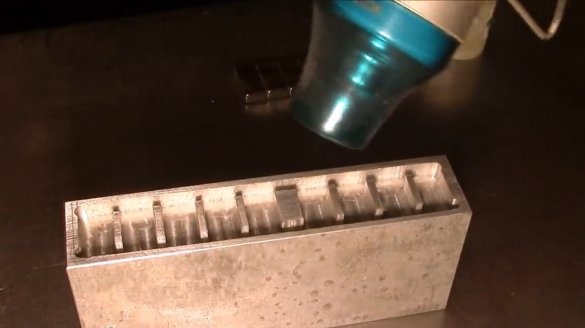

At one end of the workpiece, grooves for magnets are milled. The author will use rectangular magnets. And if he had round magnets, then this procedure would be much simpler, and one could do without a milling cutter.

So, these are the separators. He made the central one a little wider than the rest; the clamping screw will be screwed into it.

These are neodymium magnets with dimensions of 20X10X5 mm.

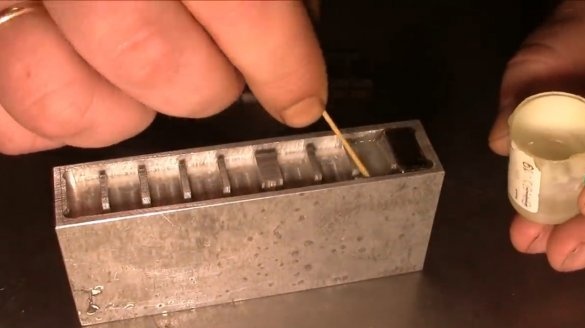

They will be glued with epoxy, and a two-component second adhesive can also be used. Before gluing the workpiece, it is better to warm up slightly so that the epoxy resin better fills the gaps.

The author made a mistake, and when he tried to glue the second magnet, he popped up and magnetized to the first. The gluing process was much easier when he used a plastic card, pressing it every next magnet.

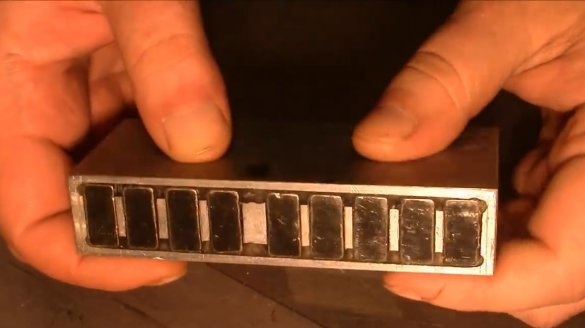

After some time, the resin polymerized, and the master begins to manufacture a protective plate. He will make it of stainless non-magnetic steel. Immediately checks how it passes a magnetic field.

Carries the marking on the plate with a steel scriber.

In order to precisely cut the strip, he magnetized it to the file, and cut off with a dremel.

Holes are drilled in the plate and body, the M2 thread is cut.

The holes on the plate are countersunk, and it is screwed to the body with brass screws.

In recent article the author told how he made such a powerful semi-automatic core. To him, he applies markings on two steel plates.

Drills holes for M3 bolts in them and the body, and cuts threads in them.

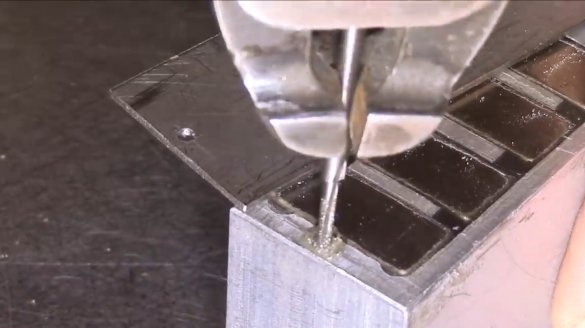

The holes in the plates are milled, they must be made elongated.

Next, the surface of the housing and plates are ground.

Thrust plates are screwed to two side walls; they will be able to adjust to the thickness of the workpiece.

You can simply adjust them so that the surface of the part protrudes above the stops.

Without such a magnetic plate, the grinding process was extremely inconvenient, the part could slip off, and fingers solemnly fell on a moving abrasive belt. And with gloves, such work is strictly prohibited.

So, device ready, and now everything has become much more convenient and safer. Under the device itself, you can put a bar.

Here is the result of grinding, everything is fine.

It is also possible to process parts on a grinder with a grinding disc nozzle.

A screwdriver with an abrasive disc, or a small manual grinder, is also suitable.

This device can be fixed in a vice, and process details manually. The separation force, provided that the blank covers all 10 magnets, will be about 40-45 kilograms. And sawdust falling onto the surface is easily removed with a damp cloth. The master also noted that the details are not magnetized after processing.

I thank the author for a simple but useful tool for the workshop!

All good mood, good luck, and interesting ideas!

Author video can be found here.