Greetings dear lovers homemade and young (and maybe not so already) electronic engineers, as well as lovers of alternative energy. In this article I will tell you how to make the simplest converter of heat into electrical energy. It is even more true to say not heat, but temperature differences. If you still do not know what the “Seebeck effect” and Peltier elements are, then before reading the article I recommend reading the relevant materials on Wikipedia. Today I’ll just tell and show how in practice all this can be applied. There are quite a lot of materials on the Internet on this topic, but I constantly did not like either the performance or the incomplete explanation of the “topic”. My homemade product is very simple, so it can be repeated by almost anyone who has ever held a soldering iron in their hands and knows how to understand circuits and understand radio components (although I will explain everything for completely newbies).

And before starting to read the article, I recommend watching a video with a demonstration, and a detailed assembly process.

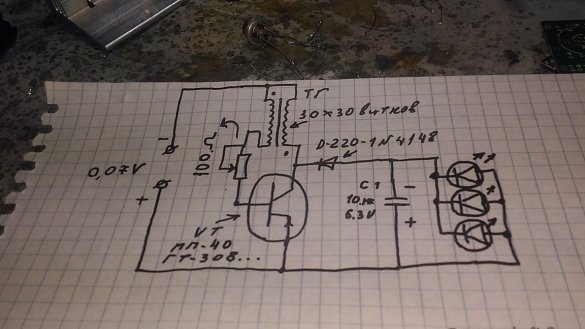

And so, here is the scheme that we have to collect.

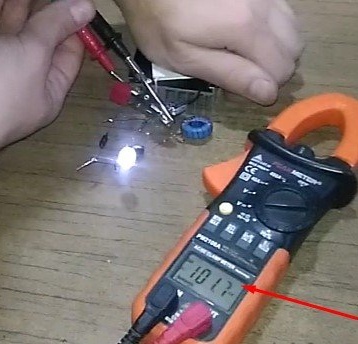

As you can see, it is necessary to apply only about 0.07V to the input for the circuit to work. It is just such a low voltage that our Peltier element will give out.

To build, we need the following:

- 1 Peltier element

- Germanium transistor mp 40

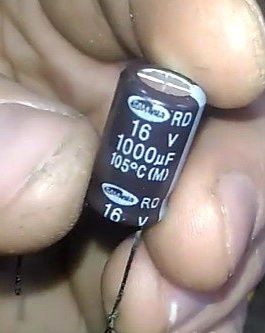

- electrolytic capacitor 16V 1000mkF

- electrolytic capacitor 25V 10mkF

- rectifier diode D220 (although you can use any other with low losses)

- tuning resistor (from 1kΩ, I use at 50kΩ)

- Light-emitting diode

- ferrite ring

- varnished wire 0.25 mm

- radiator (optional, for more efficient cooling)

And:

- soldering iron and accessories (flux, tin)

- knife (for stripping wire)

- glue (optional)

Here is an image of the components that will be required.

First, measure and cut 2 pieces of 50 cm of varnished wire 0.25 mm.

[center]

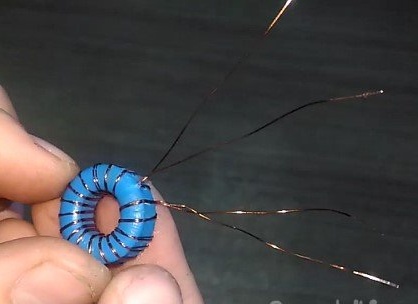

Next, we prepare a ferrite ring. We immediately pass 2 pieces of wire, make 1 turn and fix the winding with glue. I also recommend that you immediately sign the beginning and end of the windings (in any way convenient for you).

After evenly wind the wire, periodically fixing with glue.

After completing this step, something like this should come out.

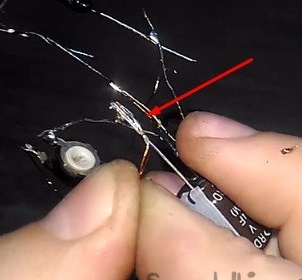

Next, we clean the ends of the windings, and then tin them.

After this, it is necessary to find the beginning of one, and the end of the other winding (for this it was necessary to somehow designate them), then twist them and solder them together.

After these actions, 3 ends should come out of the ring (there were 4, 2 twisted together).

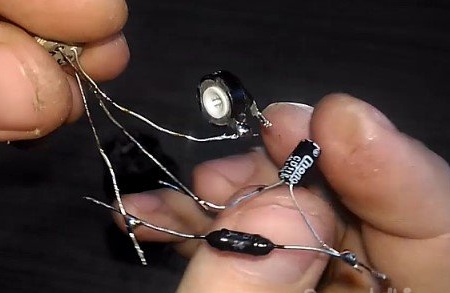

With this stage sorted out, it was the turn of assembling the main parts of the circuit.

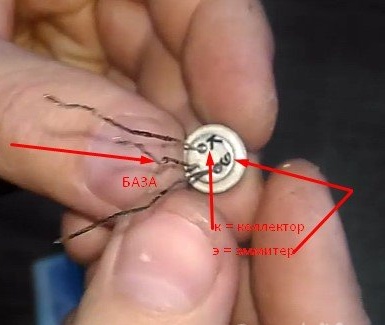

We take our transistor, and immediately sign where what is located (collector, emitter, base)

If it is positioned as shown in the figure, the collector will be on the left, the base in the center, the emitter on the right.

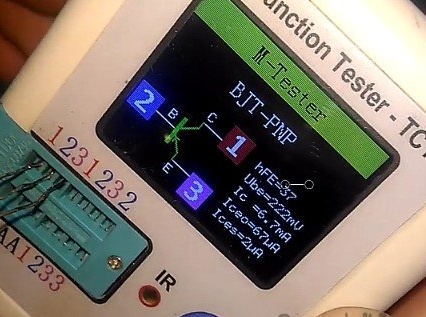

If anyone is interested, here are some characteristics of a transistor.

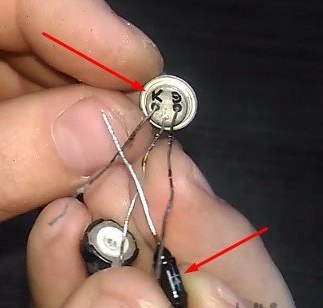

We need to solder our trimming resistor to the base (central leg) of the transistor.

Next, we take our diode in the hand, and determine its anode (triangle) and cathode (arrow).

Now solder the diode with the cathode side (arrows) to the collector of the transistor.

Then we prepare the capacitor for 10 μF which, and solder it “minus” to the output of the diode.

And the “plus” of this capacitor is the emitter of the transistor.

Thus we get "this."

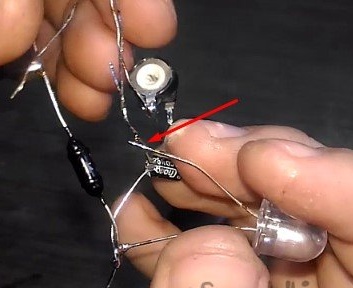

It was the turn of the LED. We solder it parallel to the capacitor and according to its polarity. That is, the minus of the LED is soldered after the diode, and plus to the emitter.

It is time to connect the ferrite ring to what we just soldered.

As you probably remember, 1 of the outputs of the tuning resistor was soldered to the base of the transistor, well, and 2 of the output must be soldered to one of the ends of the winding on the ferrite ring (the end that is not twisted!).

And the remaining free winding (again, which is not common!) Is soldered to the collector (above the diode!)

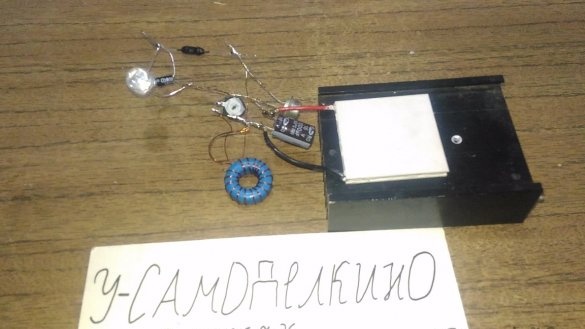

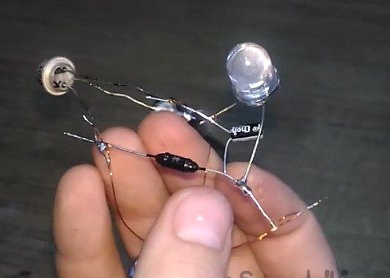

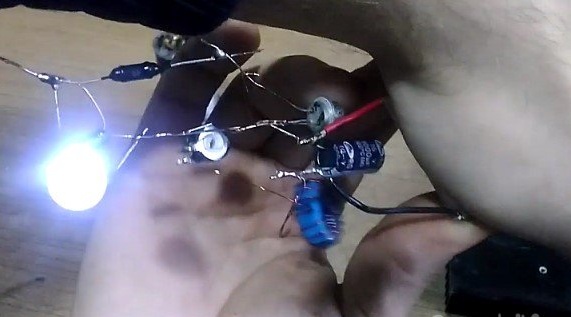

We get something like that.

Next, we take the remaining capacitor (at 1000 μF), and solder its “plus” to the emitter, and the “minus” is connected to the same double winding of the ferrite ring.

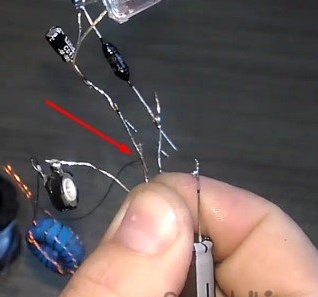

On this, the circuit can be considered practically assembled, it remains only to solder the element itself.

To do this, the black wire (minus) is soldered to the minus of the capacitor (it is clear that the one at 1000 μF), and plus to the plus of the same conder. That is parallel to him.

ALL! At this stage, the assembly is complete! What now is needed for this circuit to work? Nothing, just put your hand on one of the sides of the element and it will work.

But for a more efficient conversion, more efficient cooling of the reverse side of the Peltier is also necessary. For this, a radiator is used.

By the way, the circuit "starts" from a voltage of only 100mV!

Well, now I will express my opinion a little about this. The topic of alternative energy is developing more and more in the world, solar, wind and many others. But the topic of thermoelectric converters is raised quite rarely, although this is a very effective way of converting energy. The temperature difference is found everywhere, inside and outside the room, at different levels of the layers of soil, air and so on!

Our world is immersed in a huge ocean of energy, we fly in infinite space at an incomprehensible speed. Everything revolves around, moves - all energy. We have a daunting task - to find ways to extract this energy. Then, extracting it from this inexhaustible source, humanity will move forward with giant steps.

~ Nikola Tesla

~ Nikola Tesla