Furniture handles are one of the important elements responsible for its appearance. It seems like a small detail, but without it - no way! In addition, these items of furniture fittings are quite expensive.

In this article, Matthias, the author of the YouTube channel Matthias Wandel, offers you to learn how to make more or less tolerable door handles. Perhaps they will not be very elegant, but quite functional.

Materials

- Ash boards

- sheet plywood

- Wood screws

- PVA glue

- Acrylic lacquer.

Instruments, used by the author.

— Clamps

— Band-saw

— A circular saw

— Manual frezer

— Radius Mill with Thrust Bearing

- Belt sander

- Ruler, marker.

Manufacturing process.

The author uses standard commercial pens as a sample form. He cuts out a template from plywood, which turns out to be slightly wider than the original. But at the same time, the proposed holes for the screws strictly comply with the standard.

Under the template, the master applies the contours of the handles on a wooden beam, placing them in such a way as to save material as much as possible. True, on the other hand, this greatly complicates the work on the band saw, requires more maneuverability from it. For his products, the author selects a solid breed of wood.

After that, the author cuts the entire workpiece to the same width on a circular machine, and then cuts it into separate segments on the transverse sled.

It turned out to be quite difficult to make smooth, even cuts from the inside of the future handle. On a band saw this is very difficult to achieve. So, the author decides to resort to the help of the router.

Then it aligns the edges on the circular saw.

The author is impressed by pens with a large radius of rounding on their outer corner. In this form, they are less dangerous, and a blow to them is not so painful. The required fillets are outlined with a bearing and cut on a band saw.

Then comes the standard surface treatment on the grinder.

In pairs, the author clamps the handles in the clamps and passes the milling cutter with a radius milling cutter with a thrust bearing from the inside.

In the same way, it processes the outer edges of the pens.

The next task is to accurately drill holes along the edges of the handles for fastening to a screw.

To this end, the master drills two small holes in a piece of hardwood to use them as guide conductors for drilling.

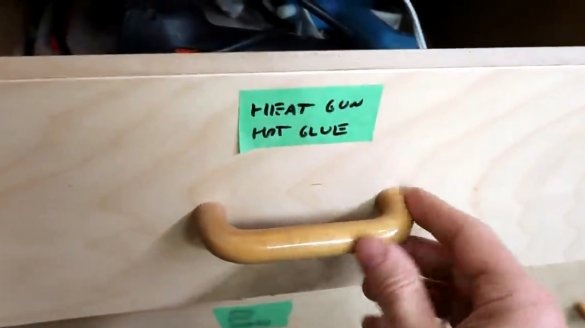

Platbands are glued to the drawers and fixed with clamps.

Then, on the basis of the first guide, he makes another guide for the very front panel of the box, placing it strictly in the center of the box.

For convenient centering of the conductor, a pre-prepared square made of plywood is used. The conductor is fixed with a clamp, and holes are drilled in the box.

All handles are varnished and screwed in place. They look pretty good. And, importantly, they are very convenient to pick up. So why do you need a furniture hardware store?

I thank the author for a simple but interesting technique for making pens for of furniture!

All good mood, good luck, and interesting ideas!

Author video can be found here.