In this article, Matthias, the author of Matthias Wandel YouTube channel, will share with you how to make dovetail joints on a regular band saw.

Materials

- Boards

- PVA glue.

Instruments, used by the author.

— Band-saw

— Clamps

- Protractor, square, mallet

- Belt sander

- Marking surface gage, marker.

Manufacturing process.

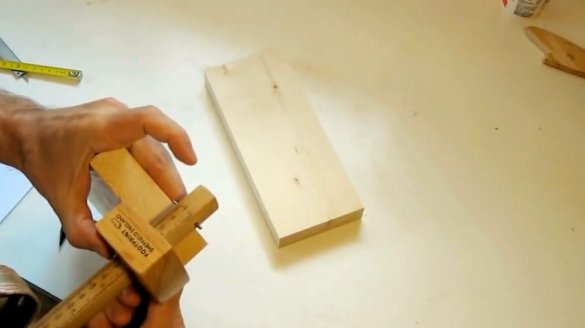

He selects the right material, and begins the process with layout.

Then he sets the marking span to a width that slightly exceeds the thickness of the processed board, and notes how deep the spikes should be.

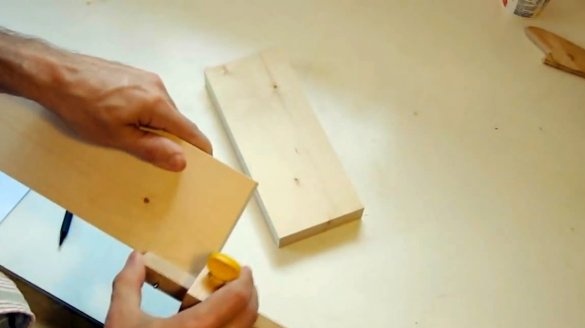

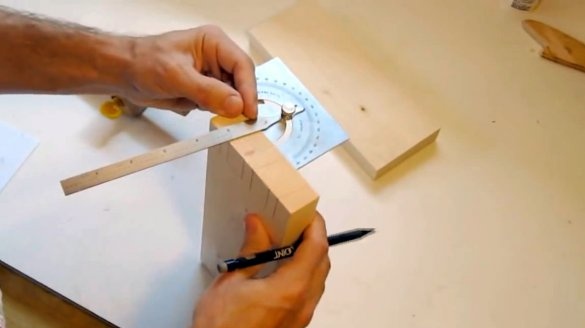

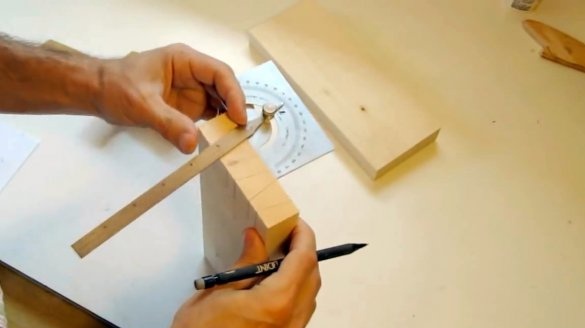

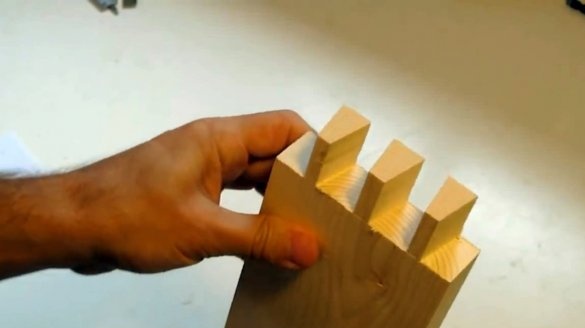

The next step, the master notes on one of the details, the boundaries of future teeth of the connection.

The author will cut the spikes at an angle of ten degrees. He transfers the marks to the edge of the board in order to have a three-dimensional picture of the object being cut and with a protractor ruler he puts off the corners at 10 degrees.

Now you have to cut these spikes. The author could tilt the table of the band saw so as to obtain the desired angle, but this would only work for one side of the spikes.

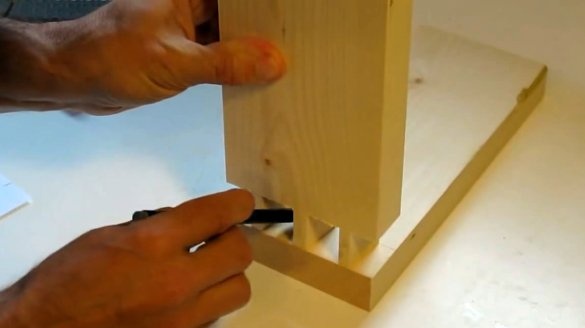

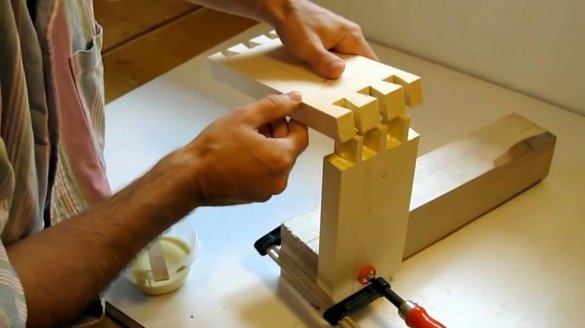

Therefore, he finds another solution: he masters the simple device for cutting at an angle, which is a simple plank with two blocks nailed to its edges. The height of the bar is calculated so that the board laid on it gives an angle of 10 degrees.

The master draws his fixture with clamps to the side of the table. The main advantage of this simple device is that, if necessary, it can be turned on the other side, deployed, as you like. In this way, it is easy to handle hard to reach corners in the slots between the teeth.

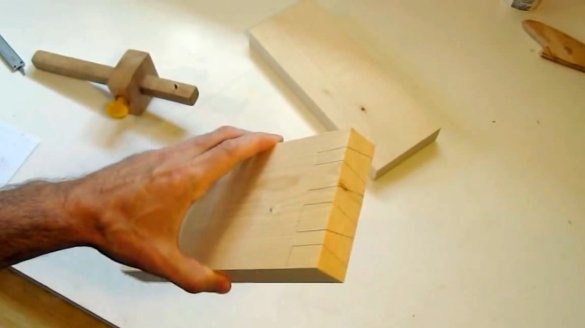

The author carefully aligns the board relative to the saw blade, the intended cut line should be flush with the blade. Presses the device with clamps, and cuts the edges with one slope on both sides of the board.

Then he rebuilds the whole structure, turns the board over on the other side and fixes it again. Now the cuts will be made with a slope in the other direction. So the sides of the stud joints are cut.

Then excess material is removed at the corners.

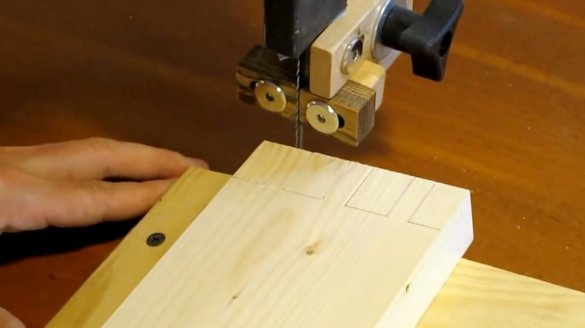

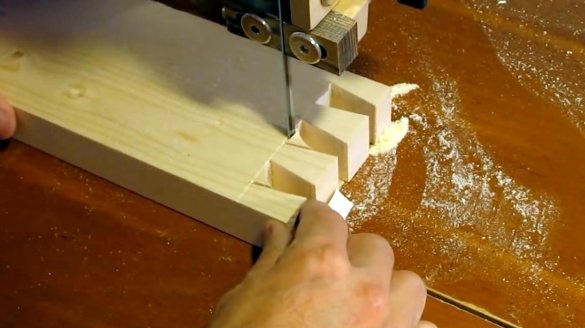

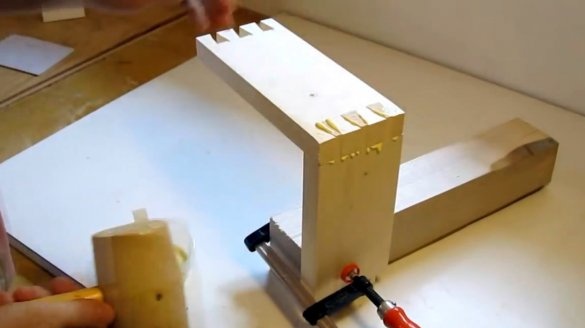

Now you need to remove the material between the teeth. This procedure will also be carried out on a band saw.

First, unnecessary elements are sawn in the shape of the letter V.

Going into each slot, the master rounds off each section at the end. It removes wood in portions until a wide opening remains. Residual material in a wide opening is easily cut with a saw.

The main thing here is not to rush!

Finishing processing the grooves between the teeth, the author, as it were, cuts the remaining fibers a little, leading the workpiece along the saw blade. It turns out a kind of grinding.

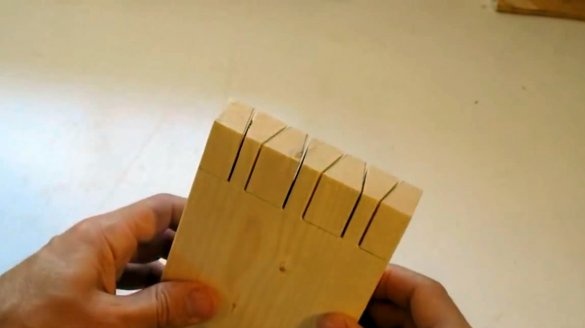

Now, with a pencil, he transfers the shape of the spikes to another board. Some craftsmen prefer to do this with a scribe knife. However, Matthias chooses a regular pencil, which gives a line of a certain thickness.

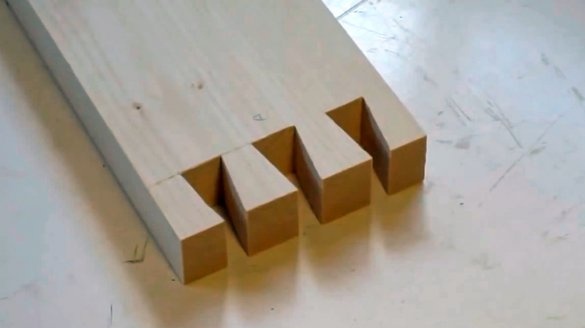

Further, by the above-described method, the counterpart of the compound is cut out. This time, cutting at an angle is no longer needed.

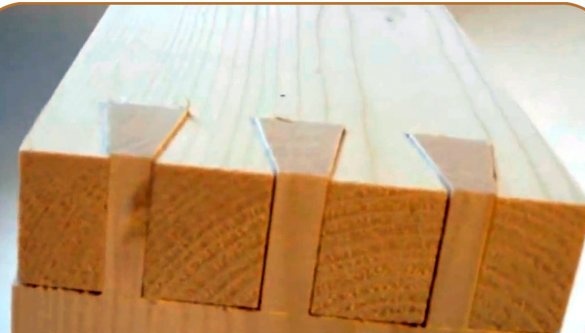

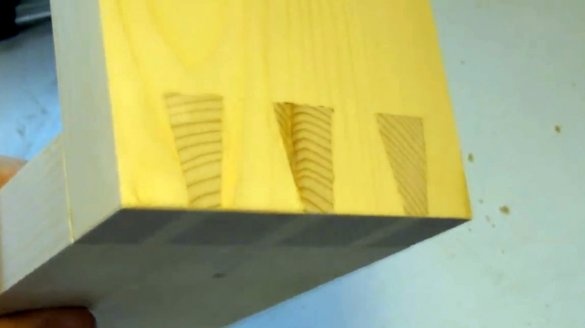

And this is what the finished connection looks like. So far it is not perfect, but pretty tightly fitted.

Matthias has to apply enough wood glue to fill all those small voids that appeared as a result of inaccurate fitting of the joint elements.

The glue makes the wood swell a little and it becomes a little difficult to snap both parts of the joint. But the master has a "means of persuasion" - a wooden mallet.

A talented inventor uses a little fine wood dust resulting from the processing of this wood. He rubbed it into the gaps with glue so that she adsorbed his excess, and filled the voids.

After the glue dries, the protruding parts of the teeth are cut off, followed by a light grout on the grinding machine.

And in front of you is a finished corner connection.

I thank the author for a very simple way to create dovetail compounds.

All good mood, good luck, and interesting ideas!

Author video can be found here.