I welcome all fans to craft, I propose to consider instructions for the manufacture of a pneumatic jack do it yourself. Such devices are commonly used in automobile workshops, but also in the garage such a tool would be useful. The pneumatic jack has a long service life, it can be lifted quickly and easily by applying pressure from the compressor receiver. Of course, you should not rely on the reliability of such a jack, therefore, when car repair is long-term or under it, always put reliable safety stops, and it’s better to immediately put auto on them. In the assembly, the project is not particularly complicated, but device very necessary, if you are interested in the project, I propose to study it in more detail!

Materials and tools used by the author:

Material List:

- air bag "LIAZ-677";

- two flanges for pillows;

- thick sheet steel;

- Hockey puck;

- square shaped pipes;

- round pipe;

- threaded rod;

- round timber;

- paint.

Tool List:

- drilling machine;

- grinder;

- welding machine;

- plasma cutter;

- vise;

- measuring tool, marker.

Manufacturing process homemade:

Step one. Pancakes

First of all, we have to make two "pancakes", these will be persistent platforms for an air bag. One platform will be below, it will be a support, and the second will rest against the car already. To make such pancakes, you need thick sheet steel. Of course, for cutting such steel it would be nice to use a plasma cutter, but with a great desire, you can cope with the work and the grinder.

The author chose the sizes of pancakes for the cushion flanges that he had. We use these flanges as templates and drill holes in the made pancakes.

Step Two Axle and wheels

We make the axle and wheels so that the jack can be conveniently moved on the floor. For the axis we use a threaded rod, insert it into a piece of steel pipe and weld. The axis is finally welded through a piece of the plate to the lower thrust pancake.

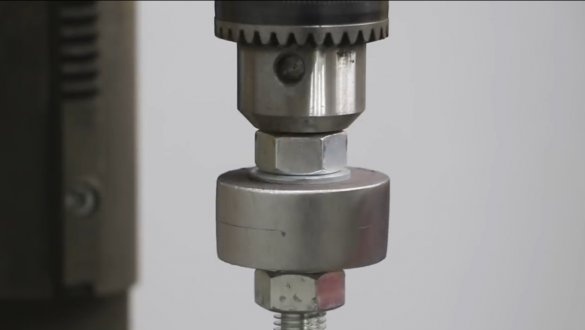

As for the wheels, the author decided to quickly make them out of thick sheet steel. We cut the rounds with a cutter, and then grind them together on a drilling or lathe. As a result, we get two simple and durable wheels.

Step Three Telescope

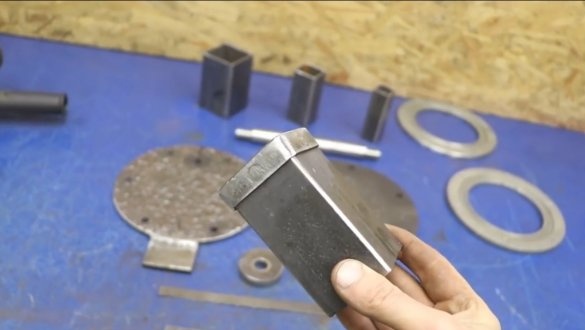

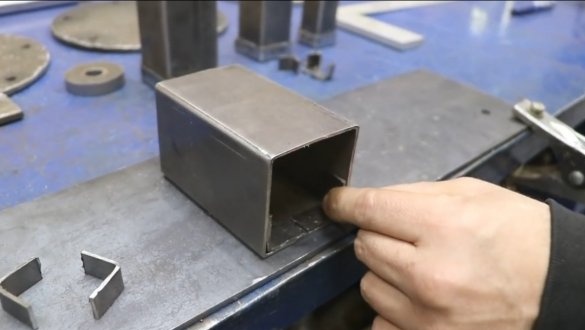

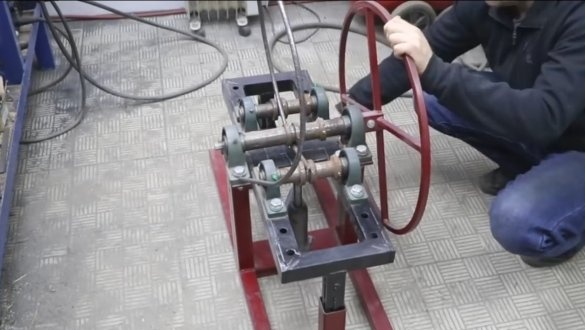

Inside the jack is a telescopic pipe, which consists of three sections.Thanks to this detail, the pillow does not move sideways, and the pipe works as a limiter so that the pillow does not inflate to a greater height than the author intended. The author made a telescopic pipe out of three square pipes of different diameters, one pipe should go into another.

Limiters must be welded on the pipes, for such purposes the author used not very thick sheet steel.

A nut is welded into the very top of the telescopic pipe, with which the upper pancake will be attached to the telescope through a bolt.

Step Four Handle and stop

We make a handle for the jack, we assemble it from a round pipe, through this pipe-handle, air will enter the air bag. We bend the pipe as you need and reliably, and most importantly, we tightly weld it to the lower pancake. Opposite the pipe in the lower pancake we drill a hole through which air will enter.

At the other end of the pipe there is a thread with which a hose from the compressor is connected to the jack.

We also weld to the pancake on the other hand the stops, which will take up the load. The author adapted two pieces of a thick-walled profile pipe for this, but this may not be enough, it is better to make the support wider and stronger, and it is better to use rubber if you are afraid to damage the floor in the garage.

Step Five Rim and support

We make a rim from reinforcement that will be worn on the central narrow part of the pillow. This rim is needed so that the pillow does not swell in the center.

The author also emphasized, which will rest on your car. Here it was decided to use a hockey puck, the author made a seat for it from sheet steel. So that the nut does not rest against the head of the bolt, the author made a corresponding recess in the washer. So that the puck does not fall out and is not lost, it can be glued.

Step Six Assembly and testing

We paint all the details of the jack and it can be assembled. The most difficult thing was for the author to put the hoop on the pillow, as well as install the flanges, it could not do without the help of a partner. The contact points of the pillow with pancakes are treated with sealant and now you can tighten the bolts, they are wrapped in holes in the flange. The result is a pretty reliable design that will break down sooner when the rubber ages and starts to crack.

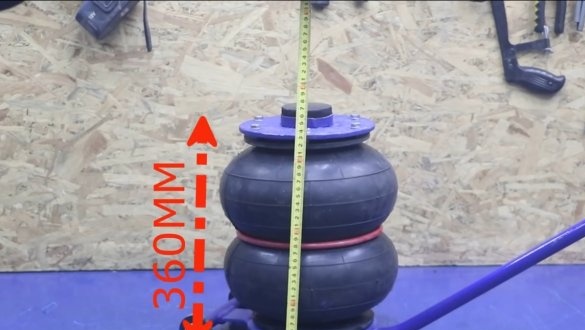

The maximum pressure that can be given to the pillow is 6.9 atmospheres, at this pressure the pillow can lift a mass of 2640 kg. The lifting height of the jack is 360 mm, and in the deflated state it has 170 mm. Everything works fine, the author easily raises the car.

The project is completed on this, I hope you liked the homemade work, and you found useful thoughts for yourself. Good luck and creative inspiration, if you decide to repeat this. Do not forget to share your ideas and homemade things with us!