In this article, the master will share his experience in manufacturing a table for cutting fabric.

Tools and materials:

-Profile;

-Welding equipment;

- chipboard;

-A screwdriver;

-Fasteners;

-Drill;

-Roulette;

-Marker;

-Gon;

-USHM;

Step One: Project

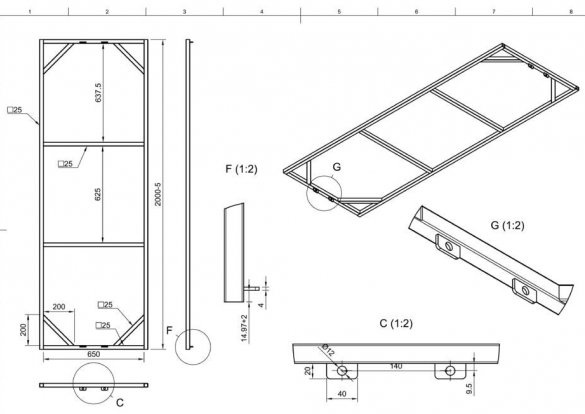

The author of this homemade lives in Russia and when designing a table took into account the state standard specifications of the USSR. In accordance with GOSTs, such tables are divided into 5 categories. This table is made in accordance with category 4, used in the manufacture of tables and desks in educational institutions.

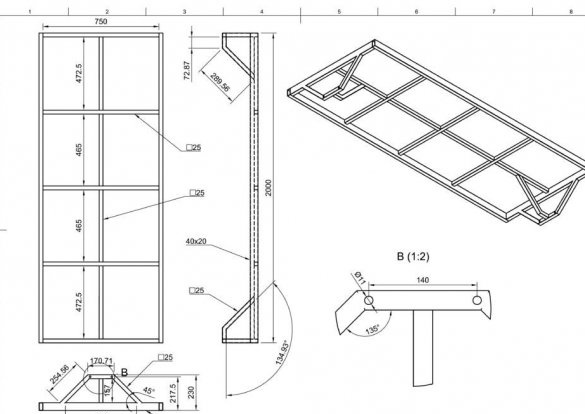

The size of the desktop is 2140x900 mm, with a height of 90 cm. The size of the shelf (under the worktop) is 1950x800 mm.

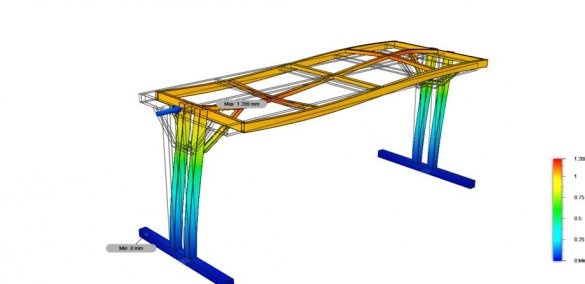

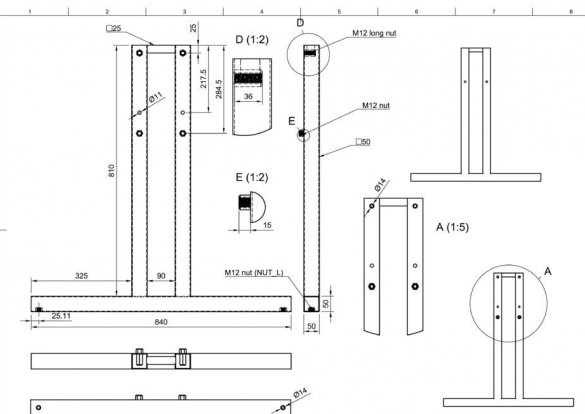

The frame consists of four parts: two legs, a countertop and a shelf. All parts are made of profile pipes: 25x25x2, 50x25x2 and 50x50x3.

Sewing_table_blueprints.pdf

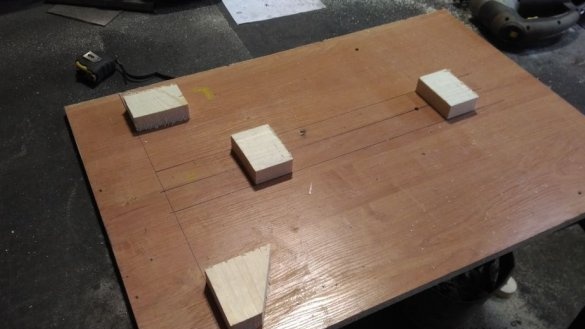

Step Two: Feet

The master makes a template. Welds the legs according to the pattern.

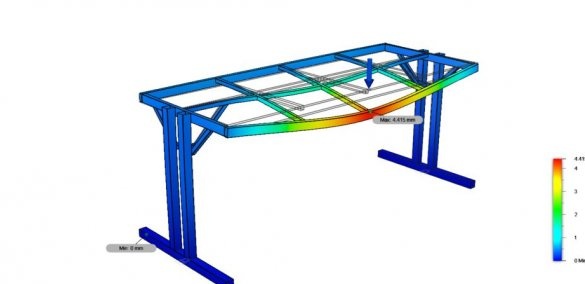

Step Three: Countertop Frame

Welds the frame under the countertop.

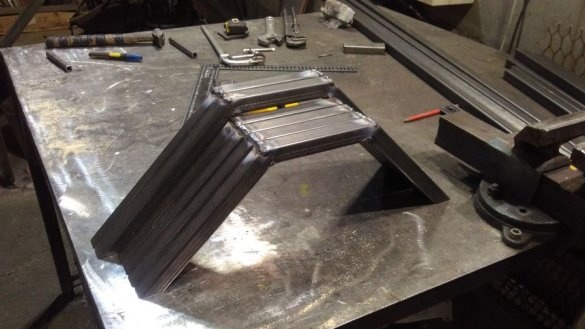

Step Four: Brackets

Further the master makes brackets. Using them, the frame of the countertop is attached to the legs. This design allows you to disassemble the table or set a different table height.

The brackets are welded to the frame, and bolted to the legs.

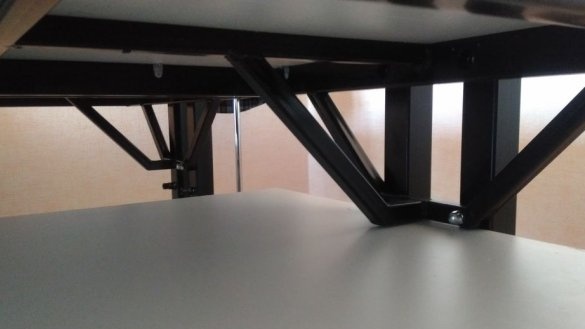

Step Five: Shelf

Welds the frame of the shelf. Welds nuts to the legs, and brackets to the frame. Screws the frame to the legs.

Step Six: Particleboard

The table is assembled and it remains to fix the countertop and the shelf from the laminated chipboard.

The cutting table is ready.