Sometimes in the manufacture of various devices or tools, it becomes necessary to make a square hole in the part. There are several ways to do this.

In this article, Igor, the author of the YouTube channel Igor Negoda, will tell you about a very unusual technique on the example of steel bars.

The same method can be applied to wooden products, in which case it will be even simpler.

Materials

- Steel blank square

- Machine oil.

Instruments, used by the author.

- Milling machine

— Semi-automatic welding

- Lathe

- Cutting disc mill

- Grooving cutter

- Vise

- Electric oven.

Manufacturing process.

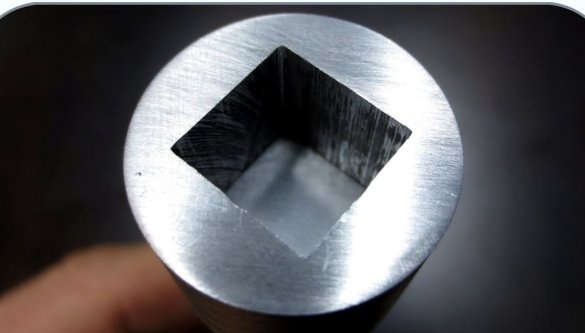

So, to make a special tool in such a steel disc, Igor needs to make a fairly large square hole. A steel square should fit tightly into it.

The author previously made such a hole, however, it was about 10 mm in size, and was performed using firmware.

First, he installs a grooving cutter on the milling machine, fixes the workpiece in a vice, and tries to mill. This mill sharpenes very roughly, it can tear the workpiece out of the vice.

Therefore, Igor sets the cutter, and makes a rough undercut to her.

The cutting mill leaves behind not very high-quality corners due to the beveled edges of the cutters. He returns the grooving cutter, and finishes processing the corners of the groove.

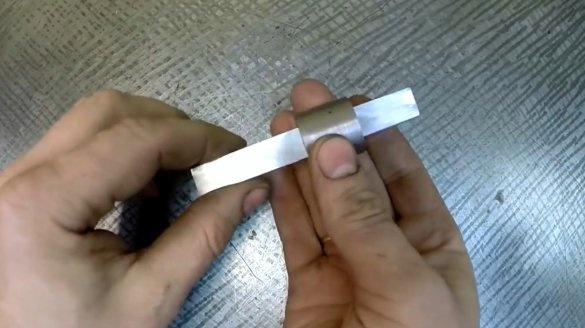

The result is such a workpiece, the desired steel square enters the groove very tightly. But is this not a hole yet? For the next stage, Igor selects a short piece of steel square, and sets it above the first.

All this business is clamped in a vice, and is seized on both sides by welding. Then the central part is removed, and the seams are boiled completely. In this case, it is better to use a welding semiautomatic device.

So far, after welding, the product has a very untidy appearance, but this will be corrected further.

The master releases the metal on an electric stove for easier further processing.

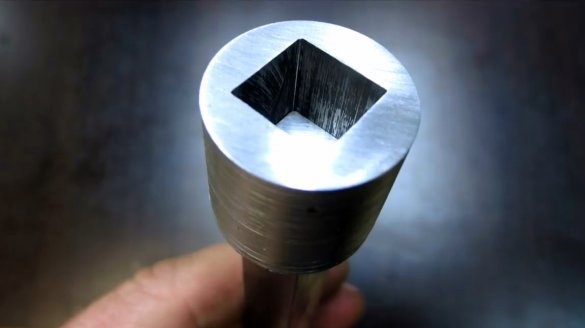

First, he processes one edge of the workpiece on a lathe. To perform the work, the cutter VK8 is used.

The workpiece unfolds, cuts, and is pressed by the tailstock. Then the outer edge is grinded.

So, Igor succeeded, the steel square enters the hole with virtually no play.

Here is a beautiful result obtained from the master.

I thank Igor for a very unusual technique for making square holes!

All good mood, good luck, and interesting ideas!

Author video can be found here.