Remember homemade "Knife forged from bicycle spokes"? So, after making the knife, the master left the rims from the bicycle wheels. And as we know, a real master never throws away anything, but puts it off until the next homemade work.

So the master had a need to make a proseivatel for compost. It's no secret that everything goes to compost, from grass and leaves to twigs and fruits. As a result, the final product needs to be sieved, since there are not processed twigs, apricot kernels, even small pebbles there (we watch the video at the end of the article).

The Master also faced the same problem. This is where the rims from bicycle wheels set aside for reserve and other bicycle spare parts came in handy.

Tools and materials:

- Rims - 3 pcs;

-Wire mesh;

-Cable ties;

- Cart wheels - 8 pcs;

-Electric motor;

-Pulley;

-Drive belt:

-Fasteners;

-Bicycle fork with wheel assembly - 2 pcs;

-A metal sheet;

-Drill;

-Wire;

-Pliers;

-Welding machine;

-Profile;

- Clamps;

-Roulette;

-Marker;

-Vise;

Step One: Sieve

The master cuts sheet metal into three strips. Bends the bands into rings and fastens them around the inside of the rims.

Cuts the required amount of wire mesh.

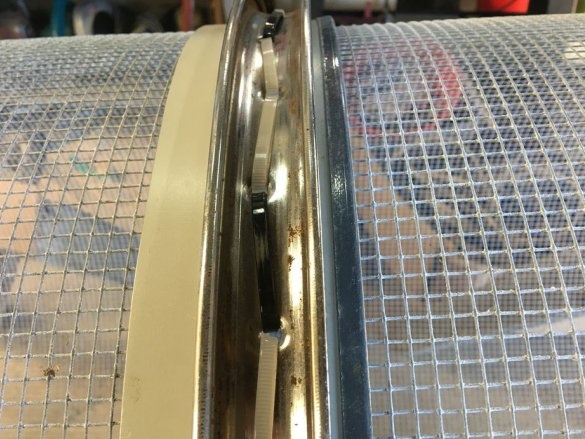

Bends the mesh with a cylinder. He puts rims on it, one in the middle and two at the edges, and fastens the grid to them with cable ties.

Step Two: Frame

Now you need to weld the frame from the profile pipe. In the manufacture of the frame, it must be taken into account that the sieve should protrude from both sides of the frame, and also that the sieve should not touch the frame. The sieve is supported by eight cart wheels fixed on top and bottom inside the frame.

Step Three: Drive

The sieve is driven by a 1.4 l / s engine. The engine transmits rotational motion through a belt onto a pulley mounted on a shaft. At the other end, the shaft is a pulley of a smaller diameter. A sieve rotates through it, with a belt.

The engine itself is mounted on a transverse beam fixed to the frame with hinges. The pulley is mounted above the engine with two profile tubes fixed in this way.The diameter of the large belt is about two meters. Belt tension can be adjusted.

Step Four: Pillars

At the bottom of the frame, the master secures the supports. In the front part, the master welds two forks assembled with wheels. In the back, secures two sections of the profile pipe. The pipes are bolted to the frame and can be rotated 90 degrees. Two pipe sections are welded across the bottom of the pipes. If it is necessary to move the screener, the supports turn 90 degrees and turn into handles.

Step Five: Painting

Before painting, the master conducts tests of the screener.

When the master is convinced that everything works and does not require modifications, then he paints the details of the device.

All is ready. With this device, you can sift not only compost, but also soil, of course, having previously selected large stones.

Below you can watch a video with an example of the operation of the prososive device.