A stationery stapler can fasten sheets of paper, films only along the edge of the sheet, then the sheet rests against the corner of the stapler. But what if the need arose to fasten the sheets in the middle? There is a solution for this case. Let's see what the master life hacker did.

So, we need the following materials and tools: stapler, four neodymium magnets, superglue, adhesive tape, screwdriver, engraver, pliers.

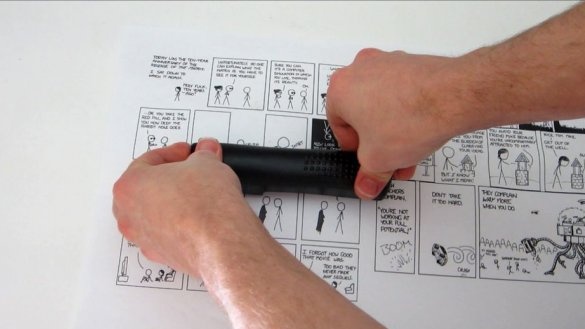

We disassemble the stapler. It is necessary to divide it into two parts. Usually they are riveted. The master drills them.

Next you need to fix the magnets.

If your magnets are larger than the holes from the rivets, then the hole needs to be drilled and the edge machined.

Two magnets will be flush with the holes in the base plate. Two other magnets will be located in the holes of the stand, while the lower side of the magnet should not protrude beyond the edge of the plane. If the spring will interfere with this operation, you can remove it.

When installing magnets, it is necessary to install them coaxially and with the correct polarity (that would be attracted) to each other. The master first fixes the magnets with tape, and then, after setting the correct position, with superglue.

All is ready. Now you can fasten sheets of any size. Alignment with magnets will show the correct positioning of the stapler parts during operation.

The whole process of upgrading the stapler can be seen in the video.