An interesting device came across the Internet. Desulfator, according to the assurances of the master

"Capable of charging and desulfurizing / rejuvenating virtually any type of rechargeable battery, provided that the battery is not completely unrecoverable."

Honestly, I have not heard of such a device before, although there is a "discharge / charge" mode at the battery charging stations for army radio stations. I suspect that perhaps this is desulfation, although most likely this is due to the memory effect. I had to climb on the Internet and it turned out that some Soviet-made memory devices, in particular Vympel 55 and Vympel 27, had such an option. Such devices are sold on Ali, but the reviews vary. Some praise, some say "useless."

What is the essence of such a device? Desulfation is the purification of plates of the battery, from lead sulfate, using special cycles of charges and discharges. In short, working by a certain algorithm, the device helps to clean the plates from sulfates. And sulfation is the main reason for battery failure.

Another plus can be considered that the device is powered by batteries and for the desulfation process, you do not need to remove the batteries from the car. Some device models can simply be installed on car.

The disadvantages include the period of desulfation. It can be from 1 day to a month. But if the device is installed on a car, then there is no particular inconvenience.

Such devices can restore, according to some estimates, up to 85% of batteries, and this is a good result. Of course, if the plates are already destroyed, then you can no longer help them.

The desulfator, which we consider in this article, also serves as a charger. Unfortunately, the master did not provide a diagram and a link to the printed circuit board and microcontroller, but he promises to supplement the article in the future, and if the link is posted, then it will be in this article. And now, the article will describe in detail the process of mounting the board and the desulfurization process.

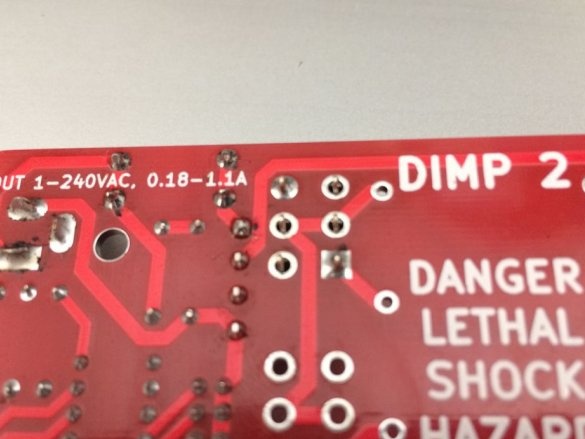

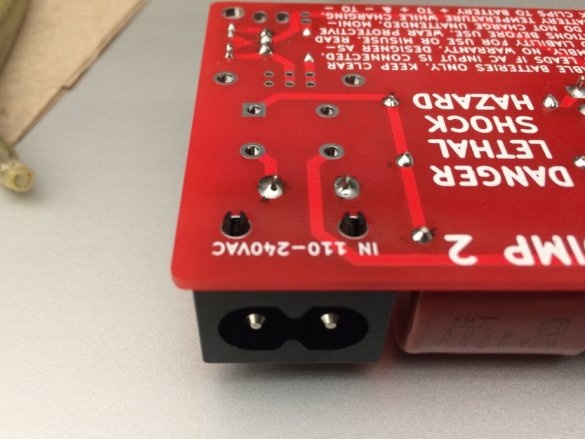

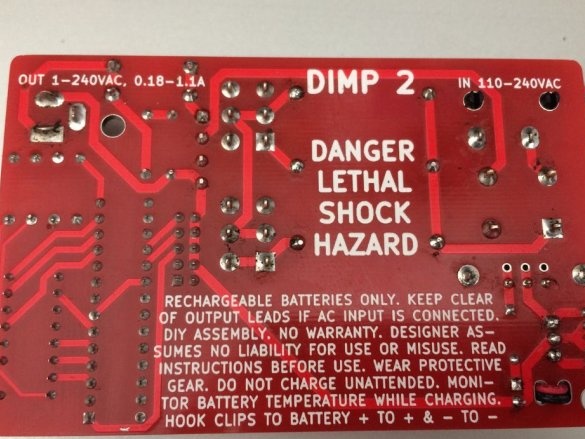

The master warns of a high risk of electric shock.

DANGER: DIMP 2 exposes the operator to lethal voltage through the output wires. Do not buy, create, or use DIMP 2 unless you are fully responsible for the safety of yourself and those around you.Only adults with the correct understanding of risks may attempt to use DIMP 2.

Tools and materials:

-List of electronic components;

- Wires for connecting to the battery (depending on the type of battery);

- soap box;

-Soldering accessories;

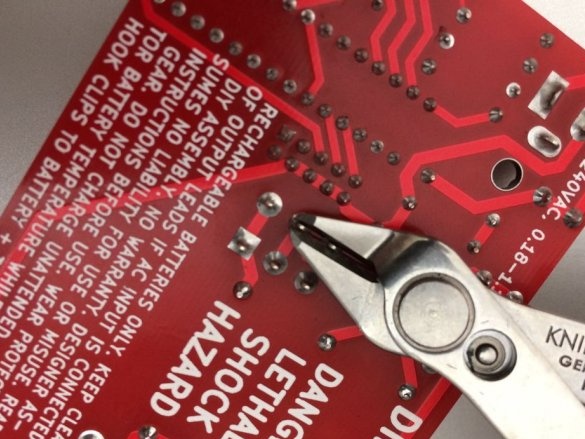

-Nippers;

Milling cutter;

-Knife;

-Scissors;

Step One: The Case

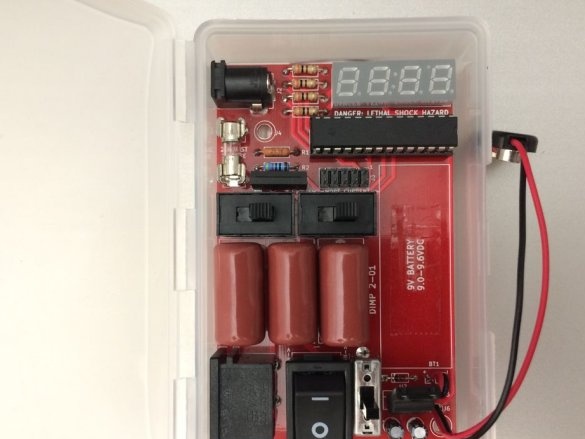

For the case, the master uses a soap dish with a lid. You need to check that the board fits freely in the case.

Step Two: Installing the Board

This is the biggest step.

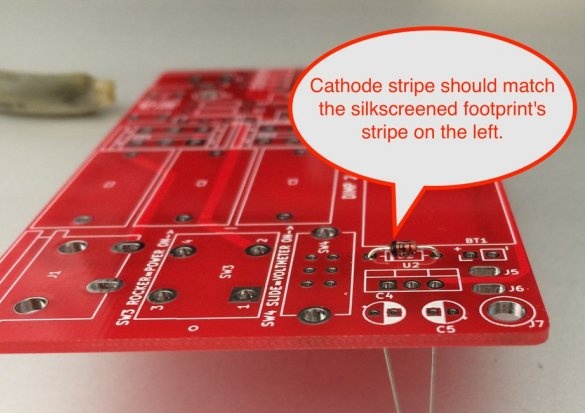

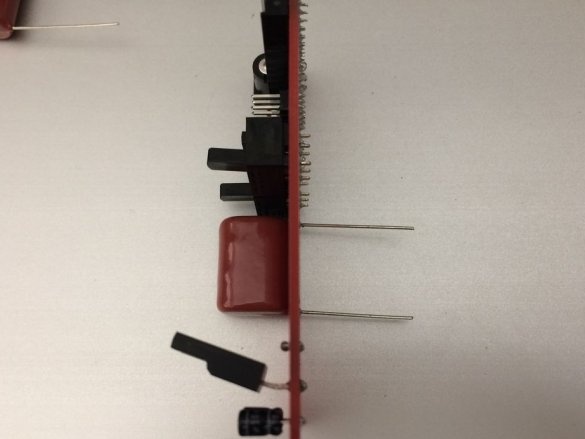

Mounts the diode on D2. Pay attention to the strip on the cathode end of the diode and insert it through the printed circuit board so that the strip is on the left, closer to the slide switch SW4. The non-striped end of the anode should be closer to the right edge of the board. Quickly solder the legs so as not to burn the diode, and cut off the protruding legs.

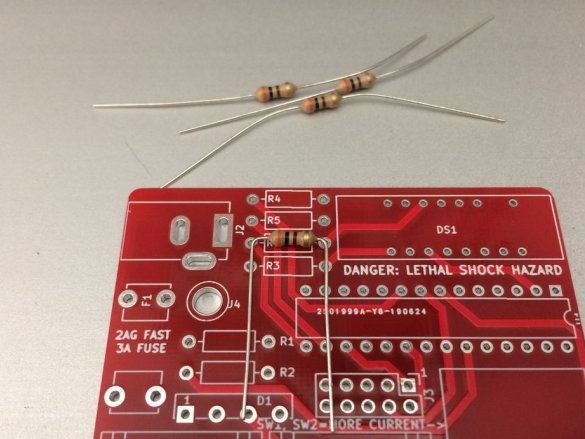

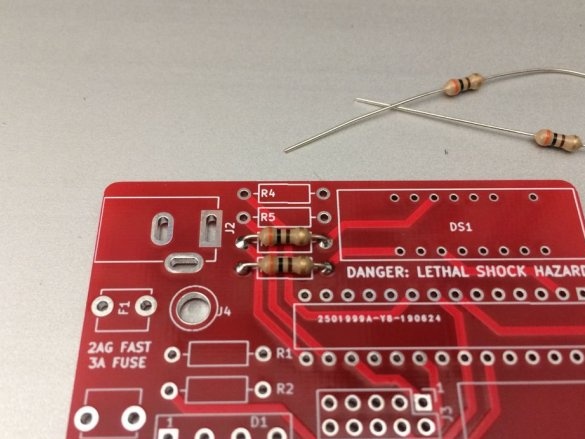

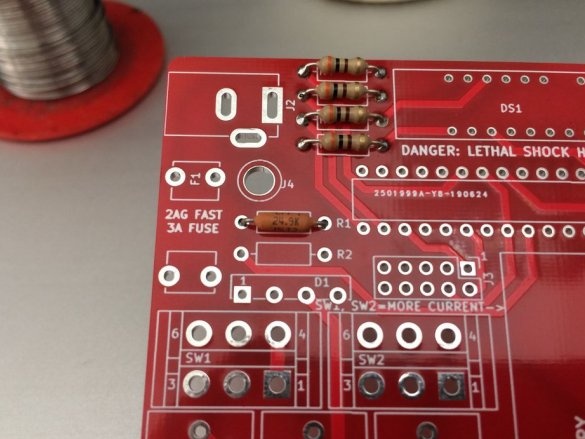

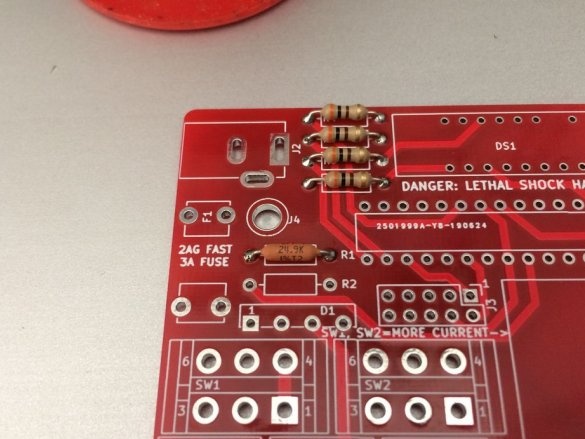

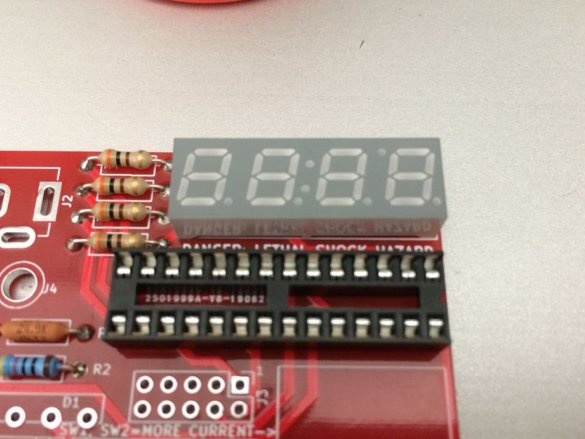

Solder four 300-ohm resistors for the LED display on R3, R4, R5, and R6. They are located together near the top edge of the circuit board.

A 300 ohm resistor has the following gradation = orange - black - brown OR orange - black - brown - gold

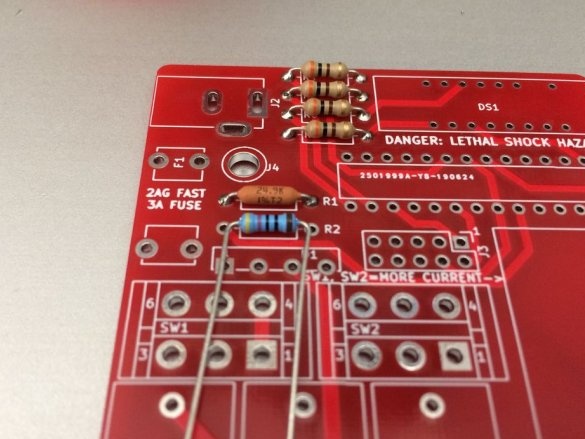

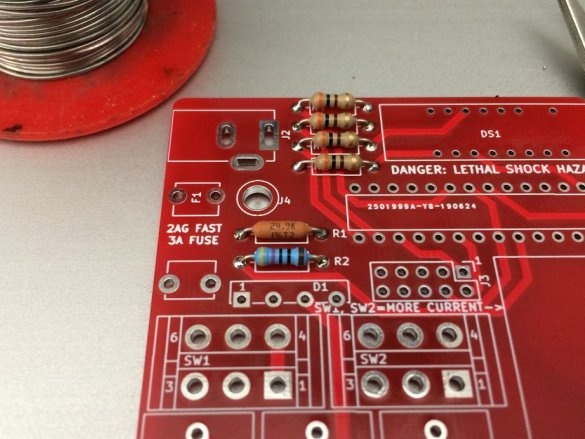

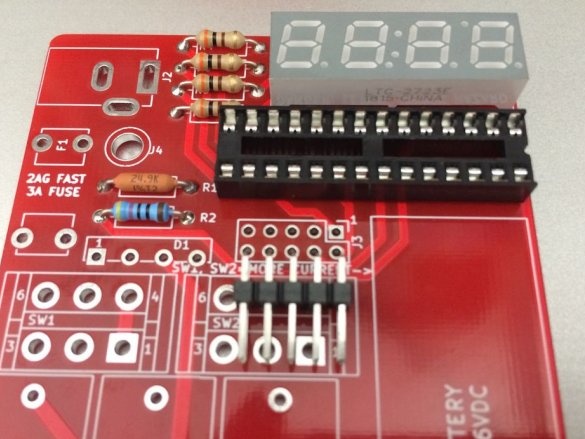

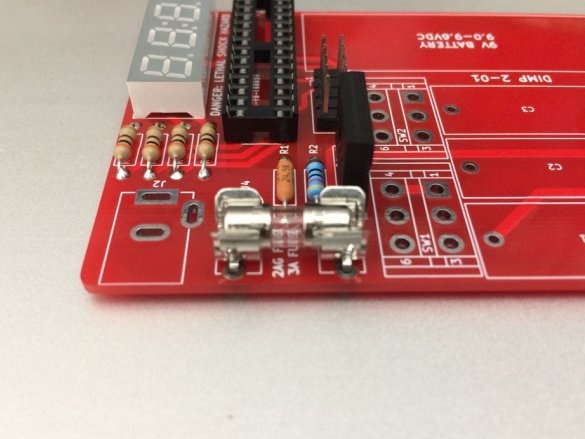

R1 and R2 - voltage divider for a voltmeter.

R1 is 24.9 kOhm and R2 is 470 kOhm. Use a multimeter to check their rating.

R1 = 24.9 thousand. 1% = red - yellow - white - red - brown

R2 = 470 ohms 1% = yellow - purple - brown - brown OR yellow - purple - black - black - brown

Solder them to the appropriate places, which are located near the upper left side of the circuit board and are designated R1 and R2.

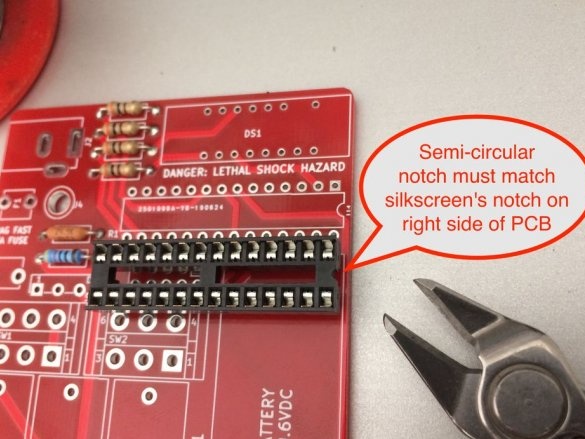

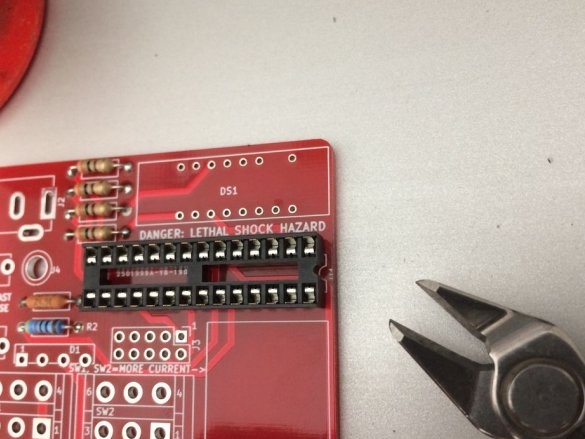

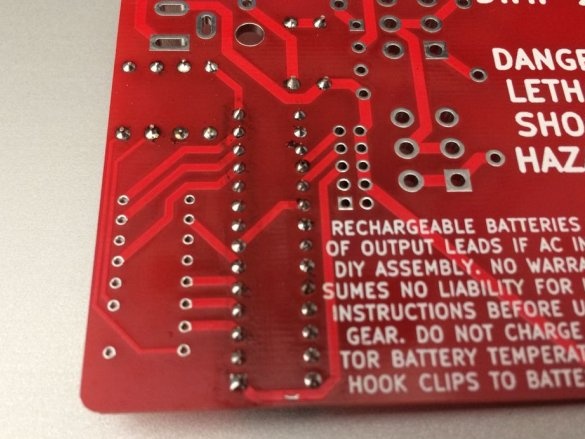

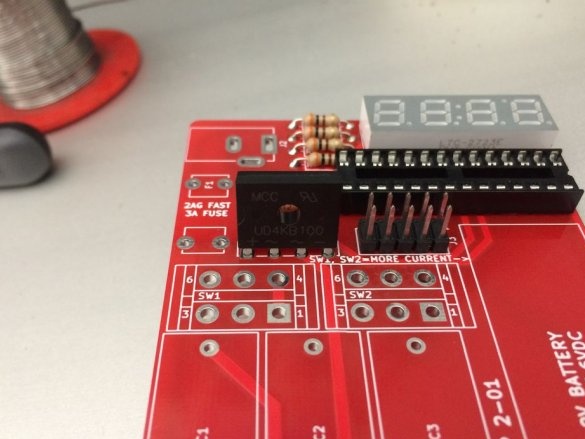

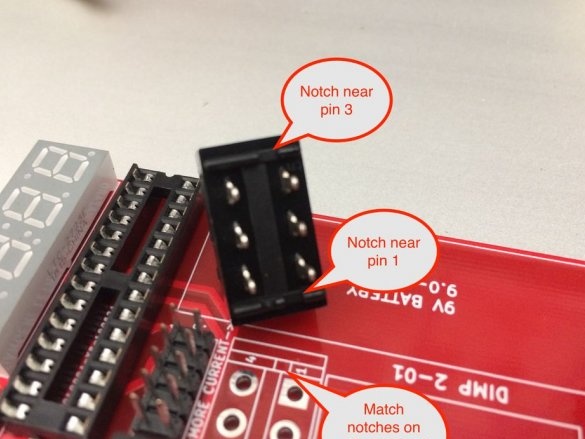

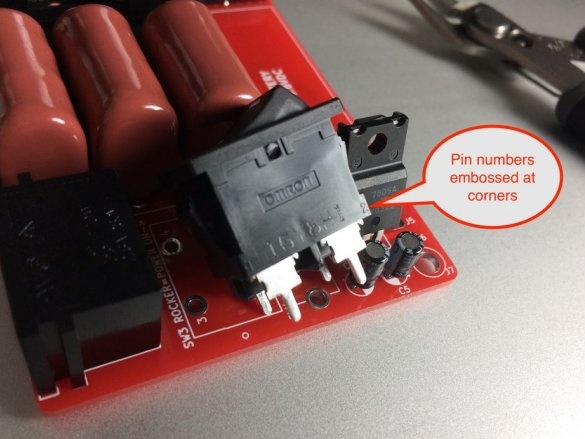

Next, you need to solder the DIP socket.

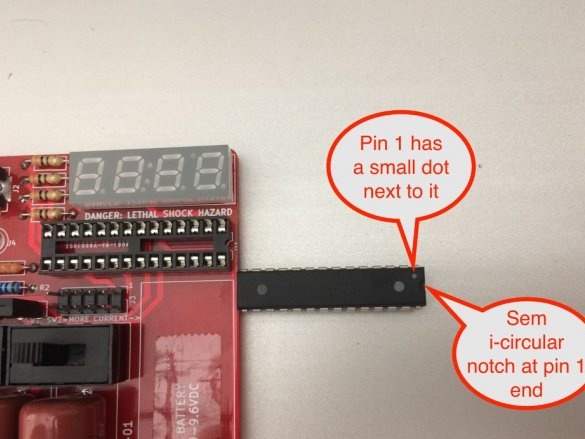

Make sure you find pin 1 on the DIP connector. A semicircular recess indicating pin 1 should be located on the right edge of the board. This is important, so double check it before soldering.

Install the socket and solder the legs 1 and 15 first, and then all the others.

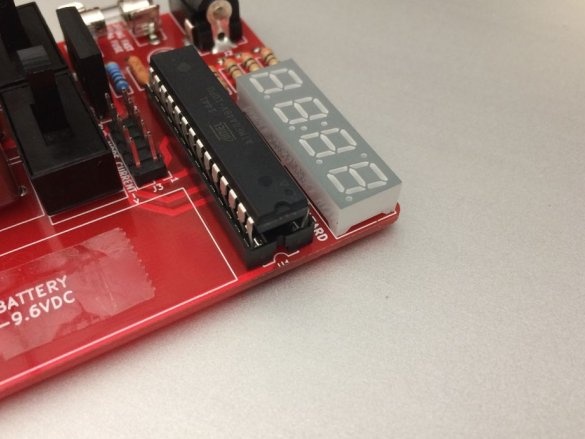

Mounts LED display. It is located in the upper right corner of the board and can be installed in only one way due to the lack of a hole for contact 10.

Solder feet 1 and 9 first. Check that the display is correctly positioned. Solder the rest of the legs.

If you want to flash DIMP 2 yourself, then install J3.

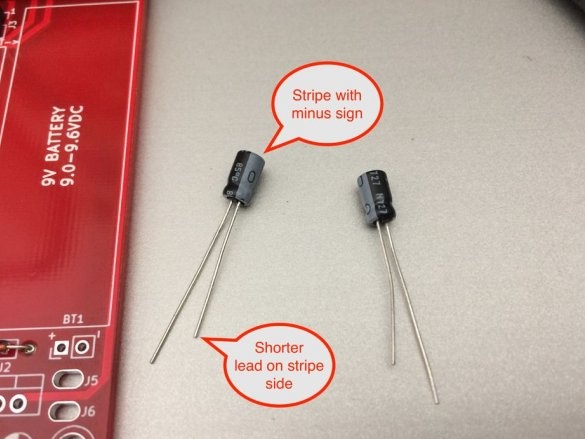

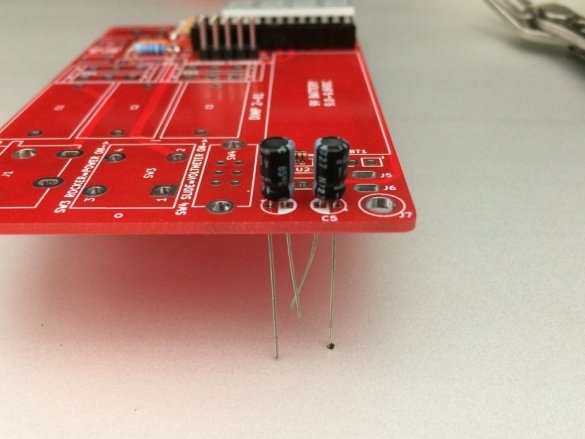

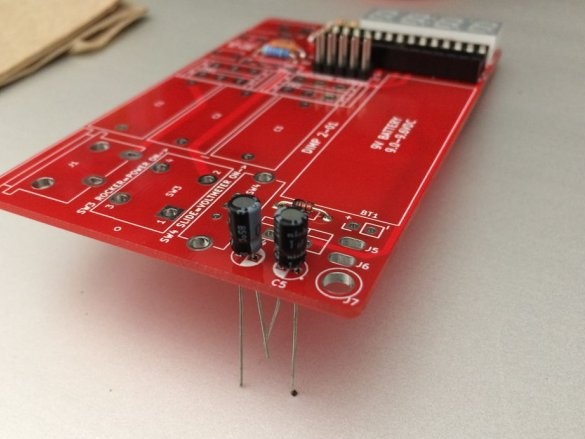

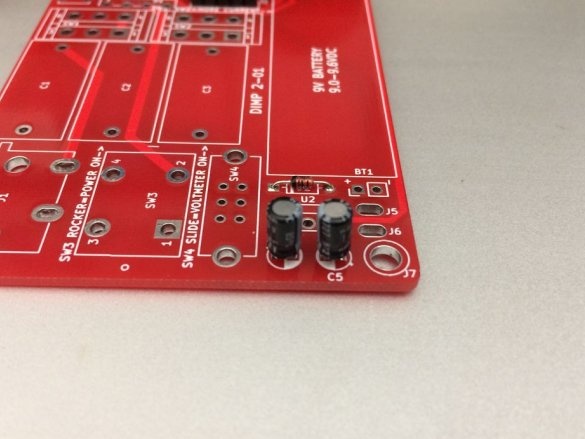

Look at the markings on each capacitor and find the negative / negative strip on one side. This side should also have a shorter leg.

Then look at the mounting location of C4 and C5. Each of them is a circle, half of which is painted in solid white. This half is for the negative contact of the capacitor.

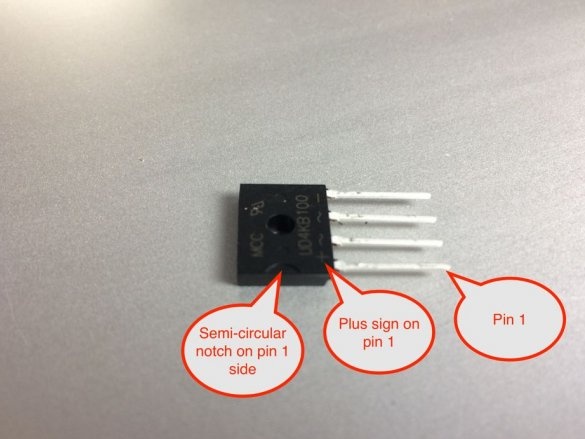

Observe precautions against electrostatic discharge with a diode bridge.

Locate pin 1 of the diode bridge. A tiny + (plus) sign should be engraved above it. If the sign is missing, then look at the case. Above pin 1 there should be a semicircular recess.

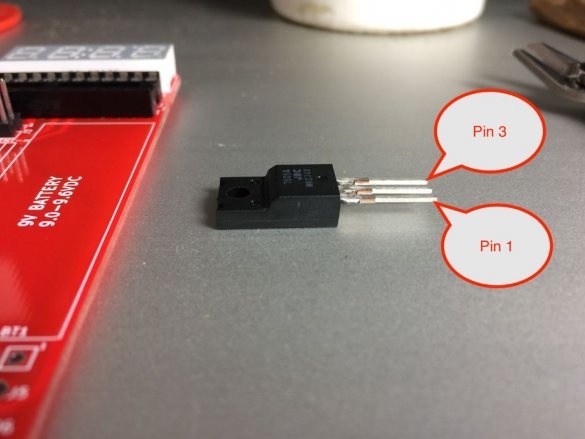

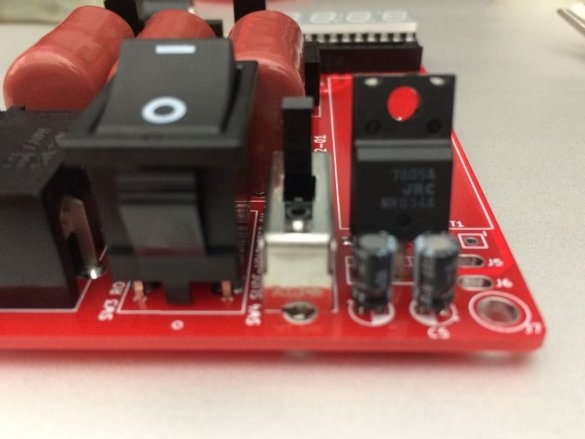

If you turn the voltage regulator with the text toward you, then the leg on the left will be 1. The regulator is installed on the contact pad U2 with the text to the capacitors C4 and C5.

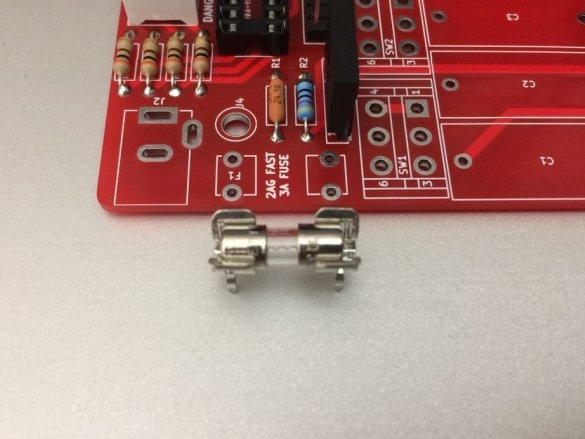

Solder the fuse holder.

Mounts the connector. The wires from this connector will go to the battery.

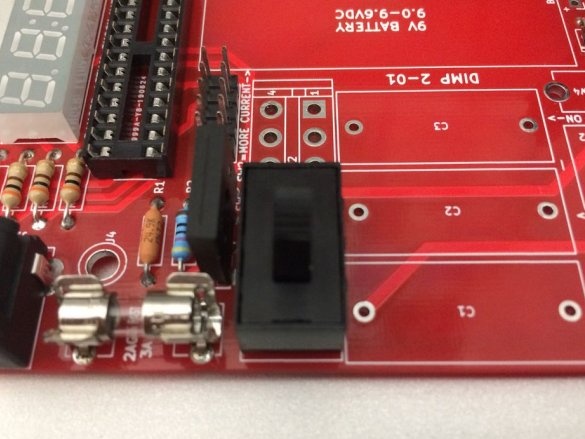

Solder two slide switches.

Capacitors C1, C2 and C3 do not have polarity and can be soldered on either side.

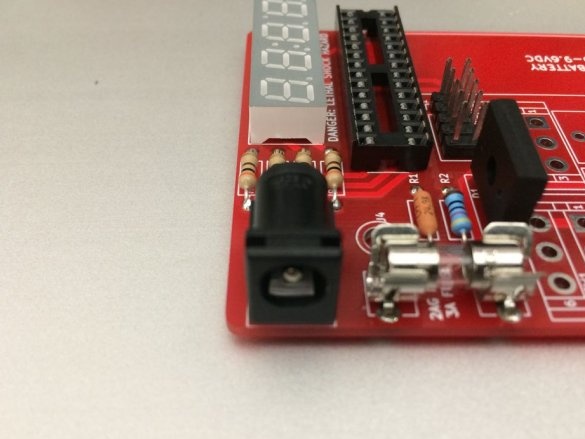

Since the AC power input is designed to be installed on printed circuit boards with a thickness of 1.4 mm, the latches do not snap on this circuit board, 1.6 mm thick.

Take a little hot glue, apply it only to the plastic latches at the entrance (not to the soldered pins), then quickly insert the entrance into the holes and press it close to the circuit board. If you don’t have hot glue, glue it on super glue. Let the glue dry, then solder the two pins.

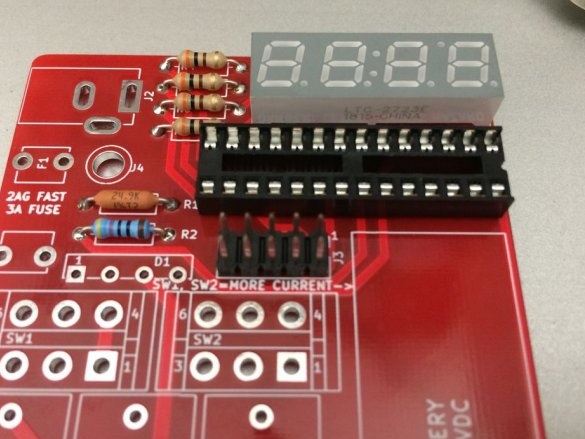

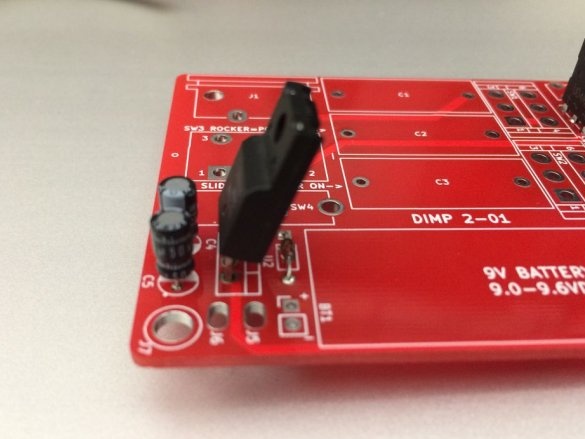

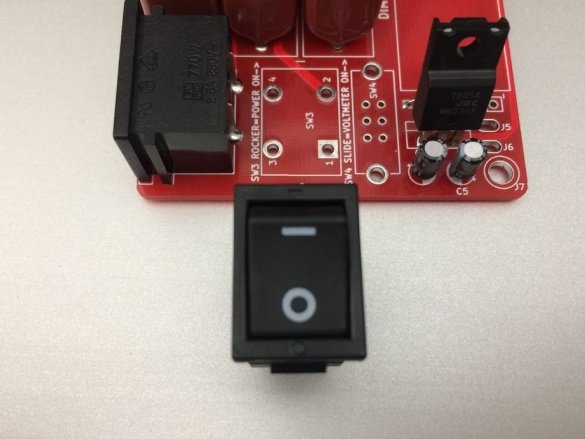

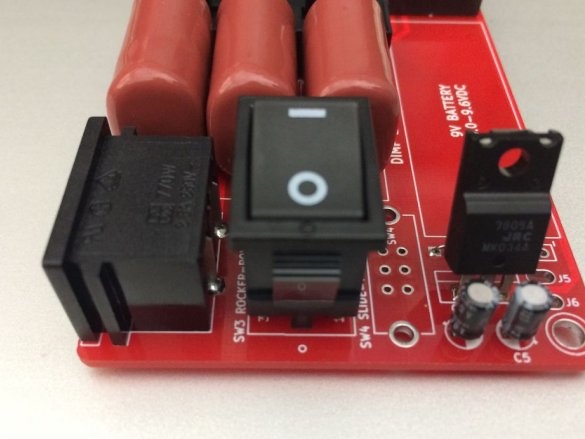

Look at the marking of the SW3 key switch. The marking |, on the switch, should be closer to capacitors C1, C2 and C3. Marking 0 (off) should be closer to the edge of the board.

The SW4 slide switch has three tiny pins and two large metal mounting pins. You will need to first solder the mounting pins.

Set the switch to the pad. Solder the two mounting pins.

Now you can solder the contacts.

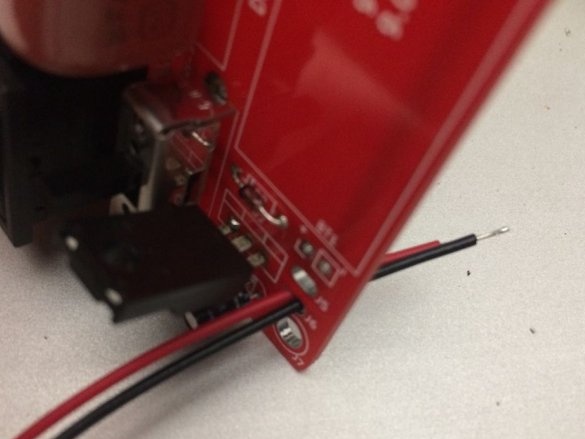

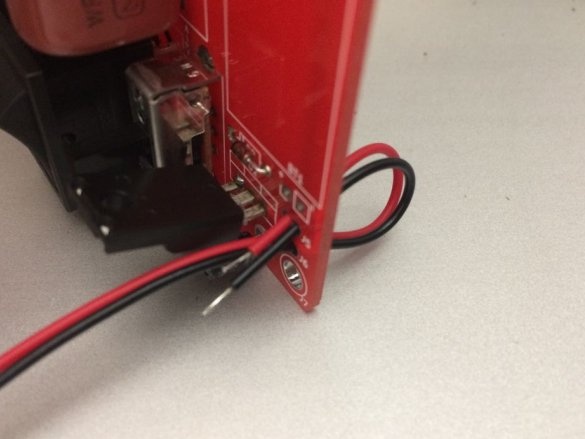

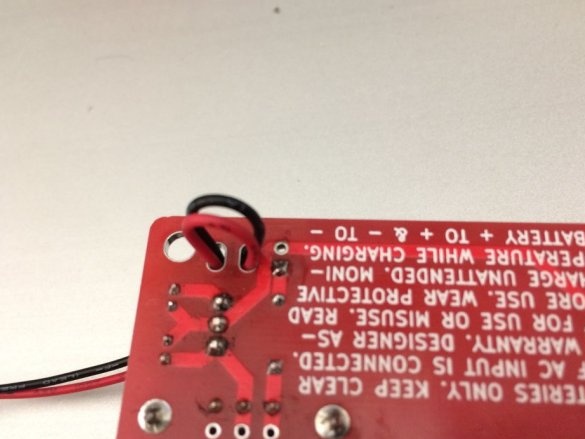

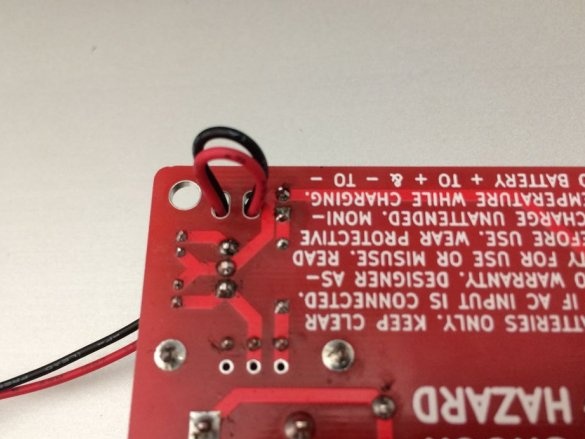

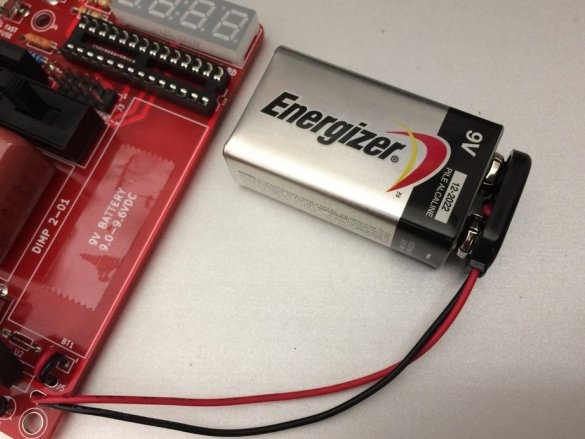

Next, install and solder two wires from a 9V battery.

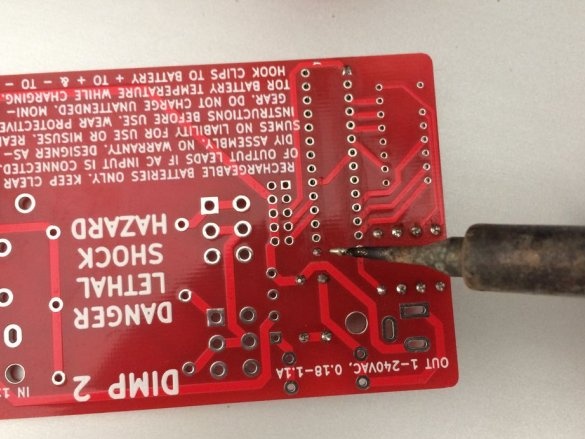

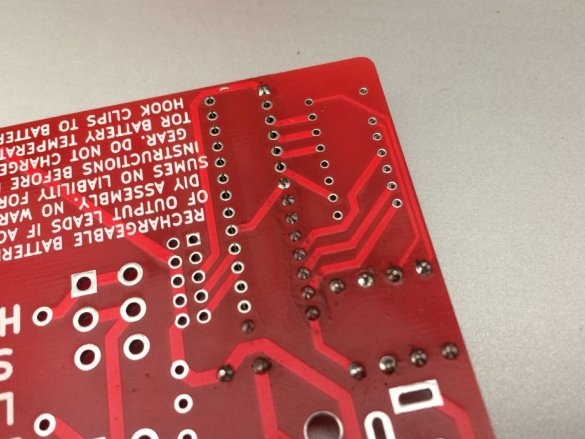

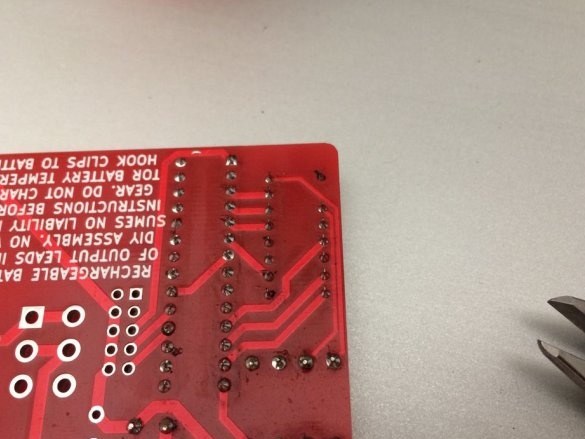

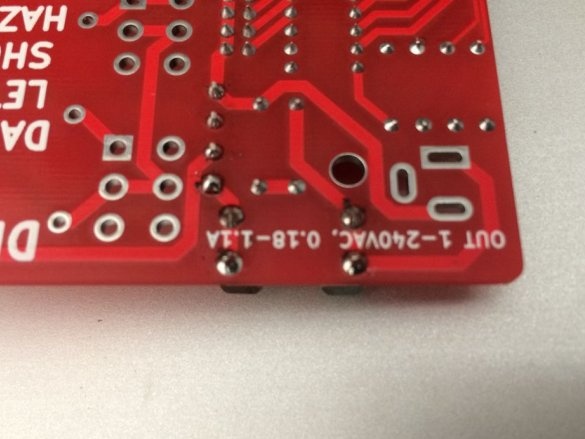

Soldering completed.Do not forget to remove flux residues.

Step Three: Connect, Verify

IMPORTANT: turn off SW4.

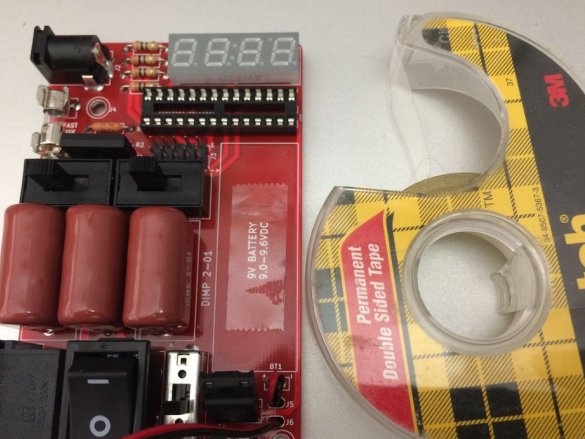

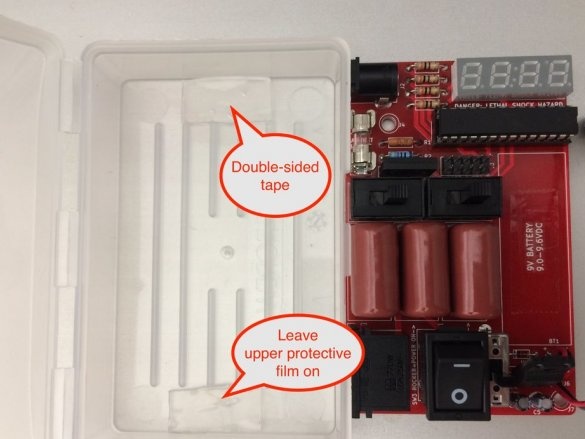

Connect the battery to the connector. Glue double-sided tape to the pad.

Before installing the ATMEGA48V-10PU in the DIP connector, you need to check that the line voltage regulator supplies 5 V to the Vcc pin. SW4 must be turned off (the drive is shifted down to the bottom edge of the board).

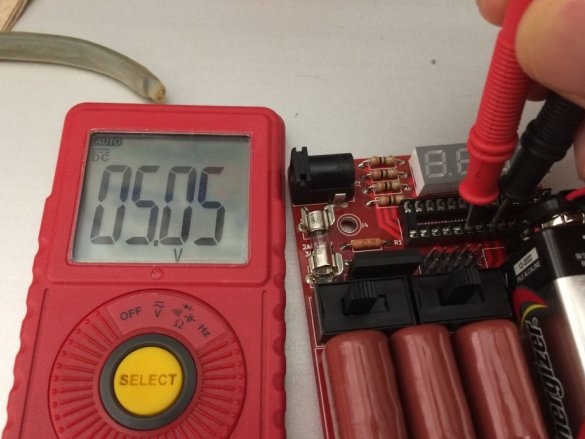

Install the multimeter in voltmeter mode and install the test probes on pin 20 (Vcc) and pin 22 (GND). Pin 20 is the sixth pin from the lower left corner of the DIP socket.

Set switch SW4 to the on position. The voltage should be 5.05 V, with a new 9 V battery.

After checking, turn off SW4 and remove the 9 V battery from the holder.

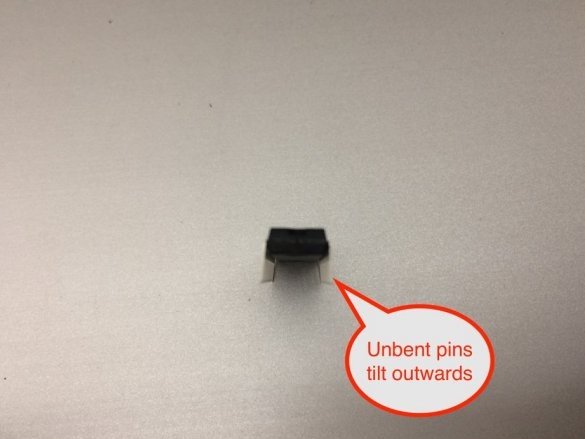

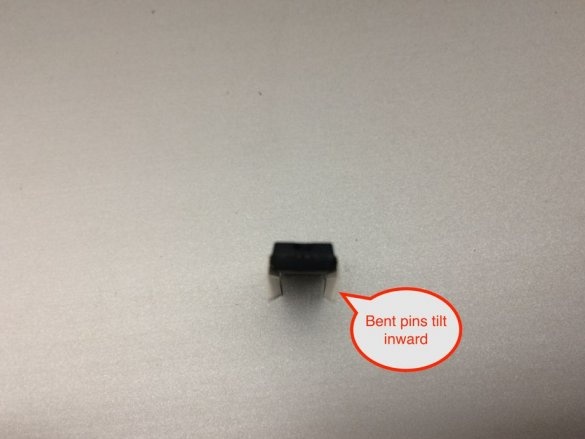

ATMEGA48V-10PU can be supplied with pre-bent contacts or not.

Look at them and see if they are straight. If the legs are not bent in advance, very carefully bend both sides slightly inward. This can be done by resting the legs on a hard surface, such as a countertop, and pushing.

Then find a tiny dot that points to pin 1 or a semicircular notch in the upper part of the microcircuit, and orient it towards the end of the DIP socket with a semicircular notch cut out.

Gently push the chip into the slot, applying even pressure to the entire chip so as not to break.

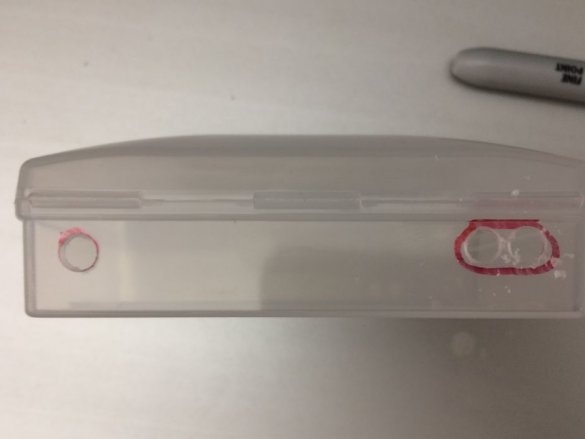

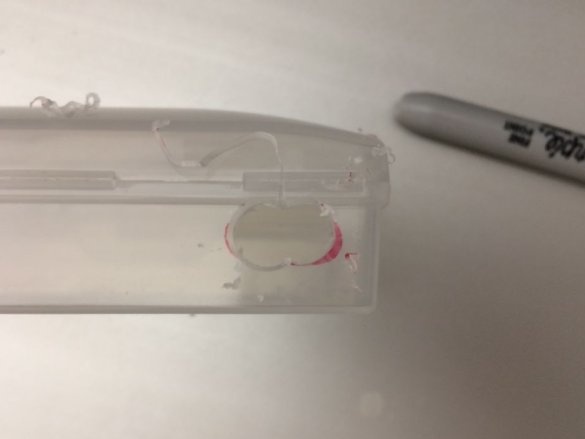

Step Four: Installing the Device in a Case

Cut the leads from the slide switches SW1 and SW2.

Installs the board in the case and marks the places for connectors. Then it cuts out the holes for them and sticks the board on a double-sided tape.

Step Five: Checking the Circuit

Check voltmeter circuit.

Make sure the circuit board is in a safe place and the AC power cord is not connected to DIMP 2. Make sure the SW3 toggle switch is off (0). Make sure the fuse is installed.

Turn on SW4. You should immediately see 000.0 on the LED display.

Turn off SW4.

On the battery, check the voltage with a multimeter.

Connect the wires to J2, then attach the clamps to the battery, observing the polarity.

Turn on SW4. The display should have a voltage equal to the previously checked multimeter.

Since you do not know who can use DIMP 2 in the future, be sure to make or buy at least one warning sticker: Danger of electric shock.

Step Six: Desulfurization

DANGER: This step includes testing for deadly high voltages.

IMPORTANT: Always wear protective equipment.

Place the DIMP 2 and the battery on a fireproof, non-conductive, stable surface.

MAKE SURE THE AC CABLE IS NOT CONNECTED.

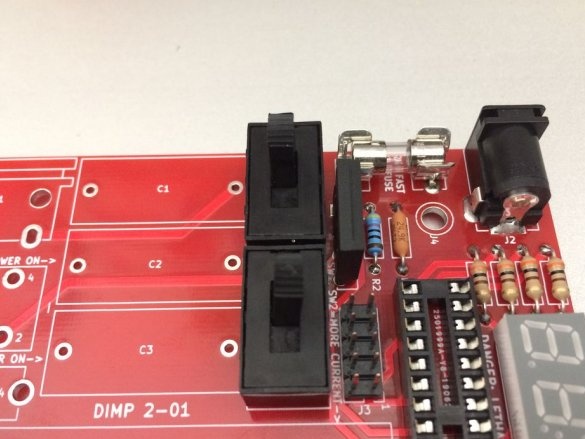

Set the two sliders according to the current required to charge the battery. For the smallest current (for AA batteries), slide both switches to the left (with DIMP 2 orientation so that the LED display is in the upper right corner). To increase the current to medium, slide one of the two switches to the right. To maximize current (for most power tool and car batteries), slide both switches to the right. As a rule, it is better to use less current.

Insert the output wires into the DIMP 2 connector.

Connect the output wires to the battery, making sure the black wire goes to the negative terminal of the battery, and the red wire goes to the positive terminal of the battery.

Turn on the slider and monitor the battery voltage.

Connect 220V to the device.

Turn on the toggle switch and watch for a slow voltage change. It should not change very or very quickly. If the voltage rises sharply and does not drop, the battery is almost certainly not fully recoverable. The voltage on the moderately sulfated battery should jump quickly, then at the rated voltage, drop almost as fast, and then gradually rise as it charges / desulfates. A strongly sulfated battery will immediately rise up, and then hours or even days will decrease to the rated voltage.

Monitor the temperature of the battery and its voltage during charging / desulfation. Heat is bad for your battery.Lithium batteries must be constantly monitored as they may catch fire. Lead acid batteries can give off gas.

Turn off the toggle switch when the voltage reaches approximately 110% of the rated voltage. NiCd and NiMH batteries for power tools typically achieve this from 15 minutes to half an hour. Lithium batteries also charge quickly. For lead-acid batteries, this process takes hours. The voltage should drop, and then find a stable value. If this value is higher than the rated voltage, everything is ready, and you can proceed to the next step. If the voltage drops below the rated voltage, you can try again to go through this cycle, but it is possible that the battery cell or battery pack may not be completely desulfated.

If necessary, you can repeat the cycle.