I welcome all fans to craft, I propose to consider instructions for the manufacture of a home-made conveyor for firewood do it yourself. Homemade the author made to download firewood in trailer. The design works from a gasoline engine, which makes homemade mobile and independent energetically. The author also cuts firewood with the help of a gasoline grinder, which stands at the beginning of the conveyor, branches and even trees with a not very thick trunk are used. The assembly of the homemade product is not very difficult, however, you need a lathe, a milling machine and other machines, well, or you can buy some finished parts. So if you are interested in the project, I propose to study it in more detail!

Materials and tools used by the author:

Material List:

- gasoline engine 3 hp (for card or similar);

- profile pipes, plates, sheet steel;

- bolts, nuts, washers;

- a small hand winch;

- finished belt for the conveyor or material for the manufacture;

- suitable wheels;

- chain transmission;

- threaded rods;

- bearings in housings.

Tool List:

- tape cutting machine;

- welding machine;

- grinder;

- lathe;

- milling machine;

- drilling machine;

- belt grinding machine;

- tape measure, marker and more.

Homemade manufacturing process:

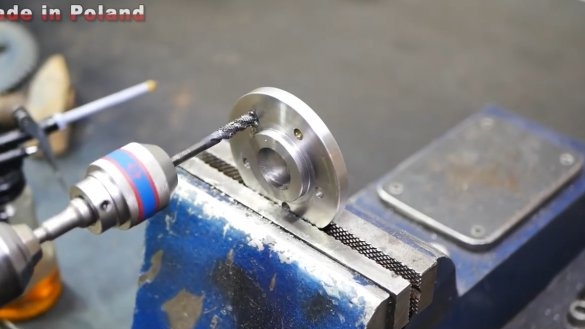

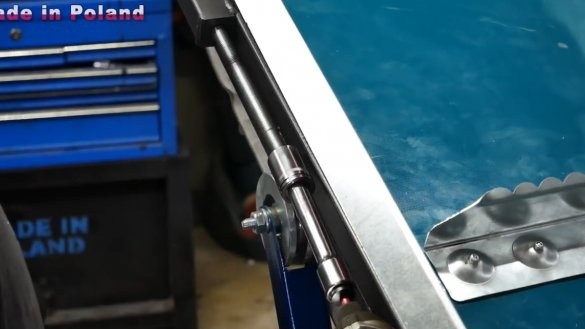

Step one. Conveyor shafts

First of all, we will produce conveyor shafts, these are rollers on which the tape will rotate. As a basis we use a round pipe of suitable diameter. The ends of the pipes need to be welded with washers, their author has machined himself on a lathe. In the center of the washers, holes are drilled under the shafts, we insert a round into the wheels and boil everything well. In the end, the author processed the details on a lathe, two excellent rollers turned out. The axis will rotate on bearings in the housings.

Step Two Driven asterisk

For the conveyor to work, the highest possible torque is needed, it is thanks to it that weights will rise in the form of firewood or others. To increase the torque, we put a driven sprocket of the largest sizes on the conveyor drive shaft. To install the sprocket, the author has carved a flange under it on a lathe. The sprocket is attached to the flange with screws.

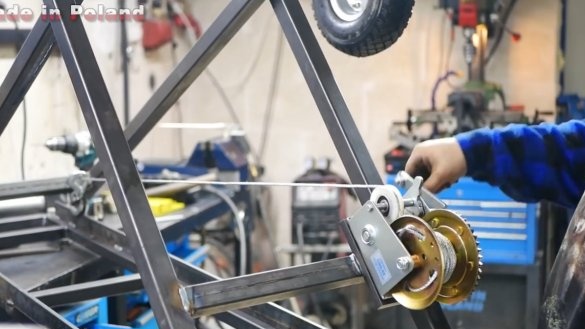

Step Three Frame and tensioning unit

We assemble the frame for the conveyor, profile pipes are an excellent material for such purposes, they are relatively light and strong. The frame design is not complicated.

The frame must have a tension unit on which the driven roller is mounted. This tension unit is a telescope in the form of pieces of pipes of different diameters, one pipe enters another. The telescope is fixed with screws and welded nuts. The tension is due to threaded rods and nuts welded to the ends of the pipes.

Step Four Lift assembly and wheels

The conveyor frame must be able to be adjusted in angle so that firewood can be loaded into trailers of different heights. Legs in the form of the letter “V” are attached pivotally to the frame, an axle with wheels is located below the pivotally connected legs. When the legs are closed, the conveyor rises and vice versa. To adjust the conveyor, the author adapted a small hand winch.

To install the conveyor, the author also made folding legs from profile pipes, do not forget to make a trailer for transporting the conveyor by tractor or car.

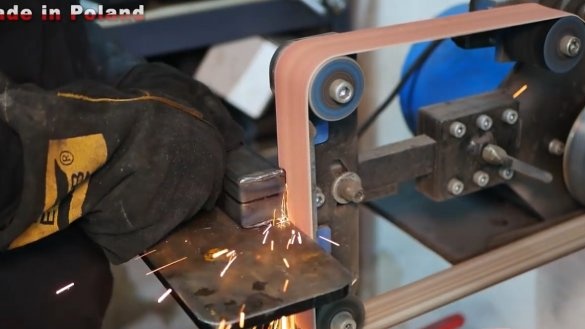

Step Five Motor

We weld fasteners for the engine from thick sheet steel, the author used a motor of 3 horsepower, such engines are used for karts. The motor is equipped with a centrifugal clutch and gives good torque at the outlet.

We also put a gas tank over the engine so that gas will gravitate into the carburetor. To adjust the engine speed, we make a handle that can be locked in position. Thanks to this control, you can adjust the desired speed of the conveyor.

Step Six Protective shield

Be sure to put a strong guard over the chain drive. Otherwise, a stick may fall into the chain, and the mechanism will fail, and this is important for safety. The author cut out the details with a plasma cutter and welded a metal shield. Fasten the casing to the frame on the cogs.

Seventh step. Gutter and assembly

We make a chute for the machine, here galvanized sheet steel or other sheet material is suitable. The author arched the gutters using a bending machine. Glue the gutters to the frame and fasten with a rivet gun.

After painting all the nodes, you can assemble the conveyor, it remains to install the tape on it. You can make such a tape yourself or you can buy a finished one.

The car is ready, you can go to the forest. The author sets the conveyor in the right place, and at the beginning he puts a stick crusher. We start the motor and set the desired speed of the tape. You can chop wood, they go straight to the trailer. Now it was a pleasure to collect firewood, you can not work at all with a chainsaw. With such useful machines, it is possible to clean entire areas of branches and deadwood.

The project is completed on this, I hope you liked the homemade work, and you found useful thoughts for yourself. Good luck and creative inspiration, if you decide to repeat this. Do not forget to share your ideas and homemade things with us!