Hello everyone, dear friends, I recently forged all my free time in my blacksmith shop until the very first snow, but unfortunately it was snowing all the time, it’s my temporary lair. Recently I did a roof repair and there was a lot of old slate left, I decided to cover myself with a blacksmith. How will I finally do it again in business. And now there is nothing to do while I’m walking on the Internet. I saw an interesting work and decided to re-publish here.

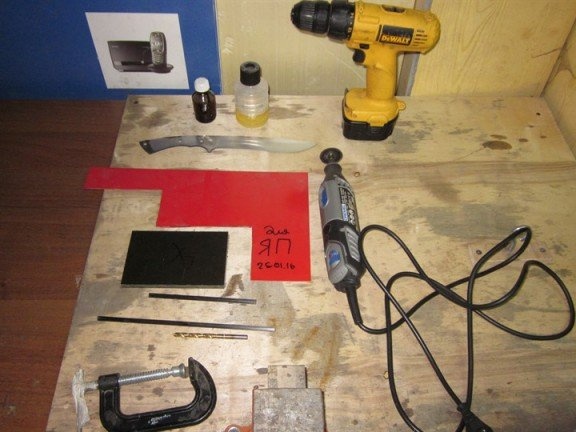

Need a tool

- Bulgarian

- Grinder

- Mikarta for the handle

- Rivets and epoxy glue

- For a sheath a piece of leather

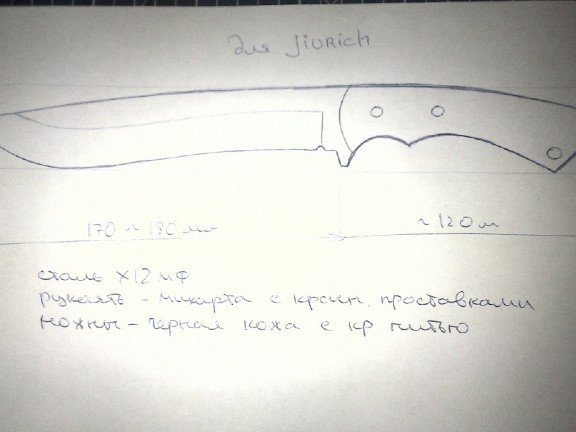

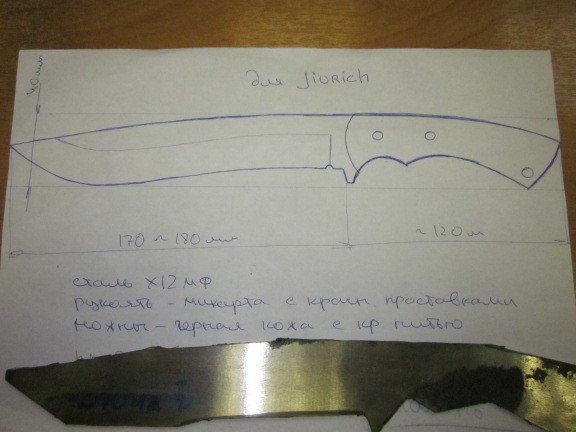

And so for starters, the author draws an accurate sketch of a knife on paper. For the blade itself, the author, thanks to a friend, uses a strip of steel h12mf 3 mm thick. Alloy steel. The presence of chromium, carbon and vanadium in the composition makes the metal solid, durable. Steel is considered instrumental. When working with metal, it is strictly forbidden to heat, so as not to overheat, you need to cool often. We cut out a sample from paper, apply it to a strip and draw a contour. With a cutting disc, the author roughly cuts the contour of the knife. After the contour is polished completely, everything that is needed is output, but the descents are not polished to the point so that the blade does not burn during hardening.

The next stage is hardening. Cool the workpiece to the handle, cool in water, it is possible in oil. Here is a view after hardening. Now the entire surface of the knife is polished and the descents on the blade are displayed. The following are the descents on the grinder with a special device.

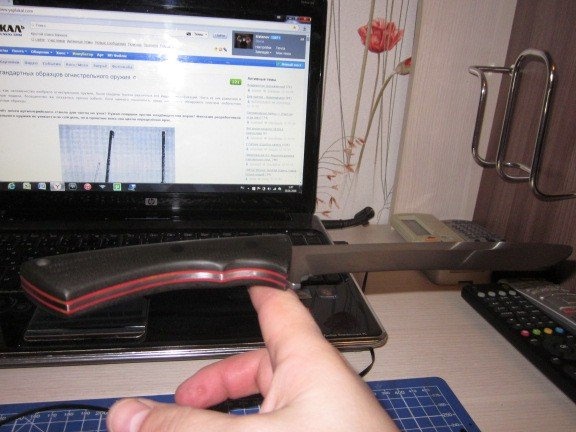

Well, that's all the time has come for the manufacture of the handle. The author took two suitable pieces of mycardum 4-5 mm thick and two pieces of red plastic. An approximate form of mikarda and plastic is cut out, all holes for rivets are drilled. Everything is ready, everything is going in its place and customized. For better gluing, the author scratches the surface. After fitting, rivets are put into the mikarda, spilled with glue, then plastic and blades, the remaining details of the stud handle are split and clamped in a vice for a day for complete drying. After drying, the desired shape of the handle on the grinder is polished. That's all, it remains to grind everything clean with fine sandpaper and polish

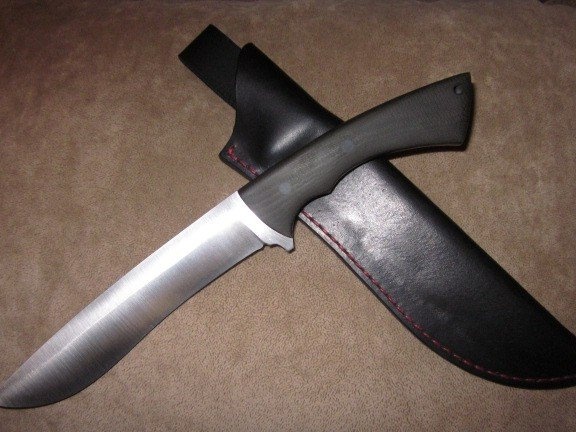

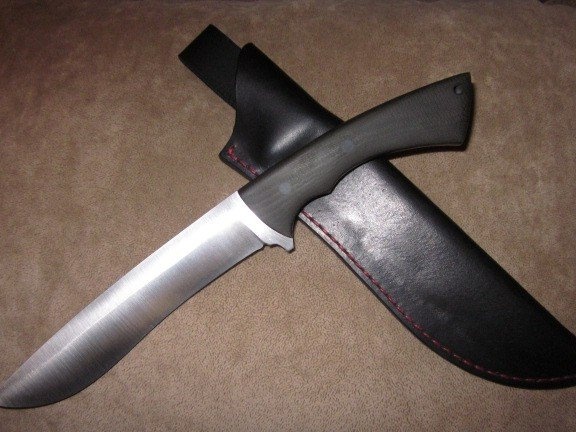

Now the author proceeds to the manufacture of the scabbard.For the sheath, the author draws the desired contour on a piece of leather. It cuts according to the pattern and so that after the firmware the knife does not cut the stitch, the author cuts the clip from the same skin. To work with the skin, the author moistens it and it becomes soft, after drying it will become hard again. The knife is wrapped with film and wrapped in leather, clamped with something suitable. After the skin is slightly dry, the scabbard is prostrated. Well, that's all the knife is ready, such a knife is easy to manufacture and beautiful in its own way.

Thanks to the author for the review and creation. Good luck to everyone and to new Homemade friends