Hello dear the inhabitants of our site and site visitors.

Many of you have your own garage or workshop. In the cold season, it is more comfortable to work in the warmth without fear of catching a cold or getting sick, so they try to make these rooms heated. But even the cheapest stove gas stove on an ad site costs from 5,000 rubles. It’s easier to do it yourself with the tool and the ability to use it. So, the author of the YouTube channel Creates DIY Ivan decided to independently assemble a furnace for heating the garage in the cold season. For stable maintenance of fire, the stove will be equipped with a blower with an adjustable damper, which will allow wood or coal to burn longer and, accordingly, a longer time to heat the room. If you are interested in this article, then let's look at the process of creating a furnace in more detail.

So, for work, the author used tools such as:

-welding machine,

-USHM and drives to it,

drill with drills

T-shirts

gas key.

The author’s basis for the furnace is a gas cylinder, which he bought at a metal receiver.

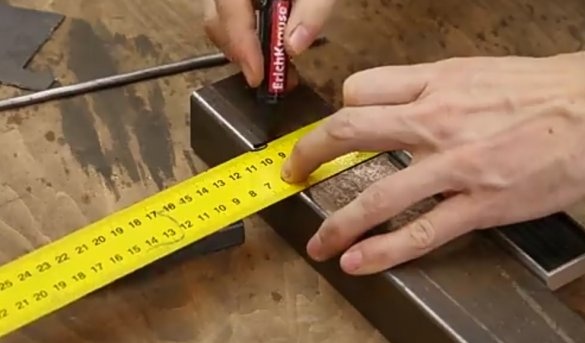

To begin with, the author completely unscrews the valve so that the remaining gas leaves the cylinder and then fills it with water for flushing. After that, he begins to make all the necessary components for the furnace. To do this, a profile pipe, metal threaded rods and a small section of sheet metal will be used. After sawing off the necessary size of the part from the pipe, sheet and stud, Ivan proceeds to assemble the blower for the furnace. For this, two through holes are made in the section of the profile pipe on the sides. A stud is inserted into these holes. A small piece of sheet metal, which will serve as an air damper, is welded to this stud inside the pipe. A washer-spring-washer-nut is put on one of the protruding sides of the stud. This fastener is necessary so that the shutter remains in the position in which the author installed it, i.e.did not change the clearance of the air supply to the furnace. A handle is welded to the opposite end.

Now balloon preparation. An aluminum plate is cut from its top. Using the template, the author marks the location of the door and cuts it along the contour with a grinder. Further, the cylinder is placed on its side and a place is marked for welding the pipe, which will serve as a chimney. The marked area is cut out. Next, Ivan takes out the preparation of the furnace to the street and makes a fire in it. As I understand it in such an extravagant way, the author wanted to get rid of the paint that painted the product at the factory.

The next thing the author does is prepare blanks for the door handle and legs for the cylinder. The handle is cut from a piece of sheet metal. A cut is cut out in the workpiece, which will be worn on a stud welded to the side of the door. At the other end, a hole is drilled for attaching to the door. The legs are made of pipe, one end of which is sawn at a right angle, and the other has a small angle for more convenient fastening and snug fit to the bottom during welding work.

The cut off top of the cylinder is cleaned of rust. Having cut off a piece of a metal plate, it welds it to the place of the twisted valve.

A hole is made near the hole for the pipe, into which a sheet of metal is inserted and welded. This is a spark arrestor to prevent them from flying into the pipe. Then the elbow of the chimney pipe is welded. Also, stops are welded in the inner space of the door opening, due to which the door of the stove will not go into the working space. The author places a door on these stops and welds a hinge to it. A bar is welded to the door itself, on the end of which a bolt is welded and a locking mechanism is attached to it, to which the author attached a handle. At a distance at which the shutter pulls out, a pin is fastened onto which the door closing mechanism is thrown preventing it from opening independently.

A rectangular hole is cut out under the door for welding into it by a blower. The legs are welded and the finished oven is covered with thermocaque for a more salable appearance.

In the end, the author turned out like this without a grate furnace for heating a garage. All residues that are obtained after burning wood or coal remain at the bottom of the stove and are removed using a dustpan. According to the author, this does not affect the efficiency of combustion. The furnace quickly warms up a garage of 50 sq.m. She performs her functions perfectly.

Thank you all for reading.