Paper is the material we use every day. And throw it away every day. Cardboard boxes, egg trays, millions of sheets of advertising newspapers and magazines. Part of this paper is recycled, and part is sent to landfills.

The master decided to try to recycle paper in home conditions, and the manufacture of volumetric objects from this paper. The master believes that 3D-molded cellulose has two main advantages: it can be a replacement for plastic and can be made from paper products of the final cycle, which can no longer be processed by traditional methods.

Tools and materials:

-3D printer;

- Paper shredder (option);

-Scissors;

-Libra;

-Blender;

-Gauze;

-Vise;

-Various paper, cardboard, etc .;

-PVA;

-Rice or corn starch;

-Water;

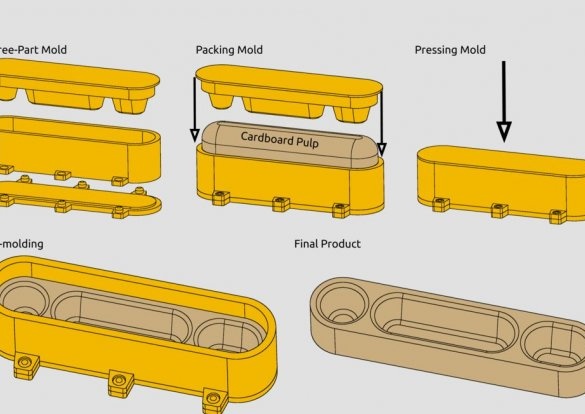

Step One: Molds

The first step for recycling paper into a new form is to create a form. In this section, the wizard will talk about his molds, and how to make your molds.

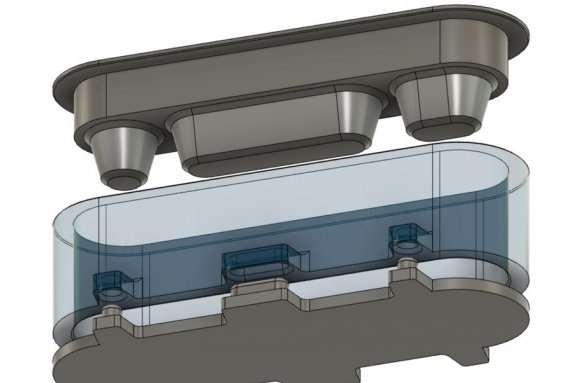

In his work, he used a three-component 3D printing system to create most of the molded pulp.

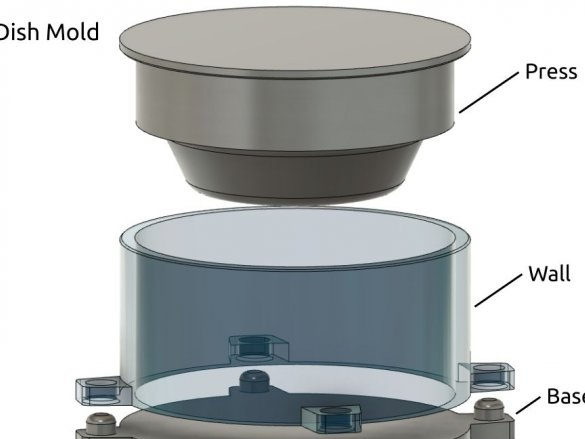

Base

A frame with straight walls that is perpendicular to the base

Press - a moving element that is pressed into the wall and compacts the paper pulp

All mold STL files are available for download at the bottom of this step and in Thingiverse.

The following files are available there:

Cup holder 60 mm (coasterMold1 / 2.STL)

25 mm cube (cube_base / cube_frame / cube_press.STL)

Triangle (Mesh_base / Mesh_frame / Mesh_press.STL)

Wave (Box_base / Box_frame / Box_Sine_press.STL)

Mt. San Antonio Topographic Map (Box_base / frame / Box_terrain_press.STL)

Dish (Dish_Base / Dish_Wall / Dish_Press.STL)

Desktop Tray (Tray_Base / Tray_Wall / Tray_Press.STL)

For the first attempt at molding the pulp, the master recommends starting with a 25 mm cube.

Mold parts must withstand strong pressure. Accordingly, you need to configure printing.

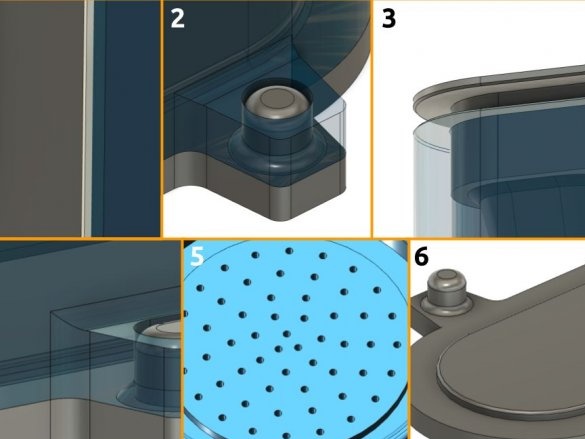

If you are going to make your molds, then you need to consider the following:

Between the walls of the frame and the press there should be a small gap of 0.4-0.5 mm.

The presence of connecting pins is mandatory.

Drain holes are only necessary in molds with a large surface area of the base. Their diameter is 1-1.5 mm.

Step Two: Paper

Almost any paper will do:

cardboard

White paper

newspaper

packing boxes

egg trays

The only paper that does not fit is glossy paper and coated paper. You can mix different types of paper.

Paper needs to be cut into small strips or pieces. A paper shredder is great for cardboard and sheets of paper. If there is no shredder, you can use scissors. The size of the pieces should be no more than 2.5 cm.

Step Three: Bonding Material

Now you need to choose a binder material (glue) to keep together the formed paper pulp. Binder material increases the strength of the final object and prevents the decay of the material upon drying. It must be water soluble for mixing with cellulose and impregnating paper fibers. The master conducted experiments with three types of binder material: PVA glue, rice paste and corn starch.

Here are the pros and cons of each:

PVA glue

Pros: it is the strongest binder, it is easy to obtain

Minuses: this is chemistry

Rice paste

Pros: organic material

Minuses: great impregnation time

Corn starch

Pros: organic material

Minuses: weak binding effect, boiling water should be used in cooking

For beginners, PVA glue is the easiest to use. The master mainly works with rice paste, because it is a strong binder and organic material.

The recipe for making rice paste.

Take the white rice. Simmer constantly stirring until a homogeneous mass is obtained.

If you cooked more than you need, then the remaining mass can be saved by adding clove oil to it.

Step Four: Shuffle

It is difficult to predict how much paper is needed. The density of paper fibers may vary depending on the geometry of the shape. Obviously, it is better to make more molding mass. Here is an approximate composition of the mass for the molding of copyright details:

Tray: 60 g

Disc: 10g

Dish: 40 g

Wave: 35 g

Triangle: 25g

Card: 25g

Cube: depends on height

The ratio of paper to binder material:

PVA glue: 30 g paper: 25 tablespoons

Rice paste: 30 g paper: 2 tablespoons

Corn starch: 40 g paper: 2 tablespoons

Mixing master produces in a blender. The last ingredient is water. The goal is to turn paper and binder into a homogeneous mixture with a minimum amount of water. Constantly add a small amount of water to the blender and run it until the mass is smooth.

After mixing, squeeze the resulting mass. The master does this by wrapping her in gauze. The resulting material should look like wet clay.

Step Five: Forming

Assemble the base of the mold and frame. Reinforcing the mold with clamps will prevent bending and deformation.

Fill the form with prepared mass. Leave some space at the top of the form. Insert the press into the mold and make sure that it is in line with the wall.

Put the whole assembly in a vice and twist them. It is necessary to tighten the vise until it stops.

Step Six: Dry

After about a day, you can remove the mold from the vise and carefully remove the press from the mold. Next you need to leave the mold to dry. The molded paper pulp shrinks when dried, so it gradually breaks away from the walls of the mold. As soon as it becomes dry and hard to the touch, you can push out an object molded from paper. For pushing, you can use the press.

To speed up drying, you can place the item under the fan.

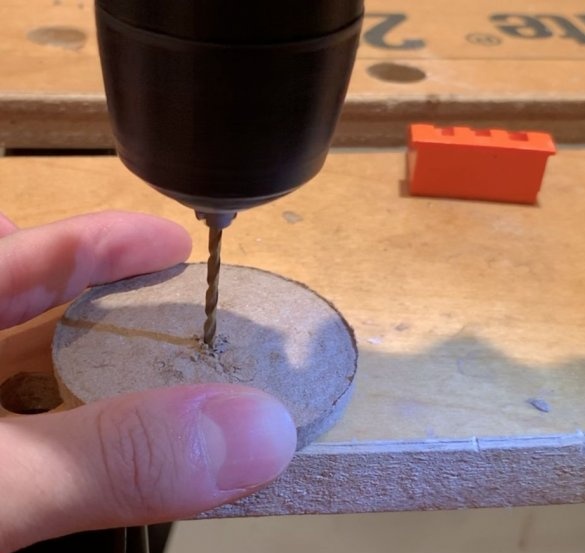

Seventh step: processing

Now you can process the resulting object, process the edges, drill, if necessary holes, grind, etc.

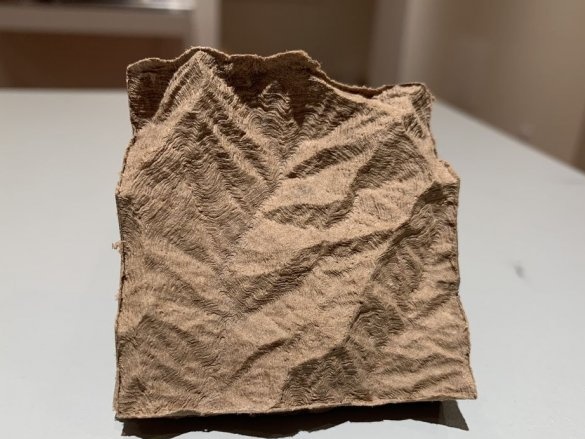

Step Eight: Result

The final molded cellulose on the surface resembles paper, but its volume gives it a wood feel. It is very hard and very similar to plastic.It tends to retain the color of the paper from which it was made, but it darkens in places that are subjected to strong pressure. In general, the stucco molding looks almost marble, especially from white paper / newspaper.

Although the master did not test the strength of this material, he says the material is surprisingly durable. No form can be broken manually. It took several hammer blows to cause significant damage to the dish.

As mentioned earlier, molded paper deforms when dried. The material expands along the pressing axis and is compressed along two other axes. The compression ratio depends on how tightly sealed the paper fibers are, which will depend on the geometry of the shape. Stronger mold compaction and the addition of cellulose will reduce shrinkage.

Since items are made of paper and water-soluble glue, it is obvious that they are not waterproof. Soaking in water quickly leads to their destruction.

Molded cellulose must decompose well in the natural environment, which makes it a good substitute for plastic in some non-moist environments.

Step Ten: Some Questions For Further Use

The wizard has not yet completed work on this project. In the future, he wants to work out the following questions.

Investigate the issue of composting products made from such a material. Over what period of time will the process of complete decomposition of cellulose take place.

Try to solve the mixing process without using water.

Find a solution for moisture protection, while maintaining environmental friendliness of the material.

Try to make large blocks and try to process them using CNC machines.

Make a hydraulic press to replace the vise.

Another question, is it possible to use material with the appropriate additives as consumables for a 3D printer? Naturally, this will not be the same eco-friendly material, but still, an order of magnitude better than plastic.