I welcome all fans to craft, I propose to consider instructions for the manufacture of a simple blacksmith furnace do it yourself. The author adapted the old industrial hood as a blower, and the piece of a large-diameter steel pipe directly plays the role of a furnace. The furnace easily inflates coal, the blower runs on a small motor. So you can quickly undo the fittings into a screwdriver, harden the knife, and so on. If the project interests you, I propose to study it in more detail!

Materials and tools used by the author:

Material List:

- An old industrial hood (can be without a motor);

- a small motor (which will pull the impeller, can be from the washer);

- corner;

- steel plates;

- bolts and nuts;

- Sheet steel;

- pipes;

- a piece of pipe of large diameter.

Tool List:

- grinder;

- welding machine;

- drill;

- roulette;

- marker.

Manufacturing process homemade:

Step one. Motor installation

That hood, which the author found, was without a motor, it was just a case with an impeller inside. As a conclusion, we need to find a suitable motor that can rotate the impeller and supply the desired amount of air. The motor from the Watt washer is enough for 200, but you can look for something else, and not necessarily for 220V. The higher the engine speed, the greater the amount of air that the blower can produce.

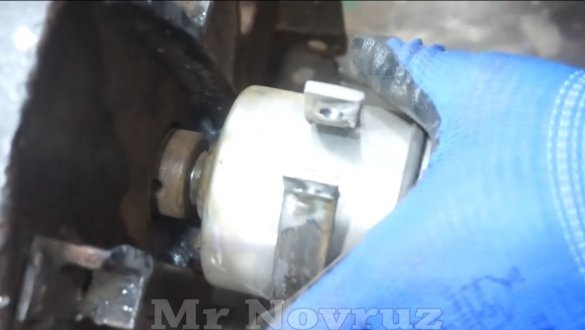

To mount the motor, the author welded a piece of a corner to the blower and made a clamp from steel plates. We bend the plates in the form of a motor and tighten with a bolt and nut.

Of course, you will need to make some kind of adapter to put the impeller on the motor shaft. The author turned on the motor, the impeller rotates quickly.

Step Two Cap

We make a cover for the blower, for this the author cut out a part from sheet steel, the decision was made to fix the cover with bolts and nuts. In the center of the plate, you need to cut a hole through which air will be sucked in.

Step Three The final assembly of the furnace

The author screwed a steel sheet to the outlet of the blower, and welded a piece of steel pipe in the center, through which air goes into the furnace.

The author himself made the furnace out of a piece of pipe of large diameter, or you can simply weld a metal box. The pipe must be connected so that it does not become clogged with ash, however, it should be blown out.

Having welded legs to the furnace, it can be started, first we kindle chips, and then we load coal. After some time, the author blew coal to a yellow glow, this will allow to heat steel to the level of hardening and forging.

The project is completed on this, I hope you liked the homemade work, and you found useful thoughts. Good luck and creative inspiration, if you decide to repeat this. Do not forget to share your ideas and homemade things with us!