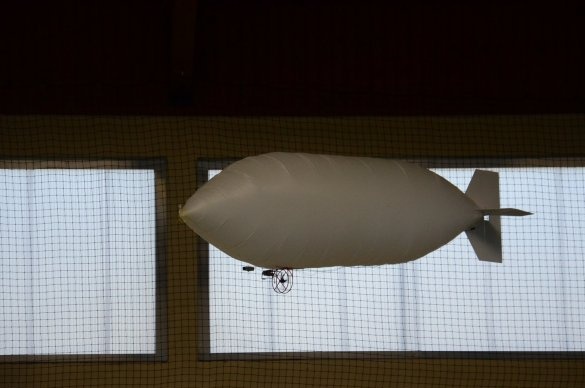

I welcome everyone. This article discusses the manufacture of simple home conditions of a model of a radio-controlled airship. Model of this airship is based on the Silent Runner model from the team Windreiter.

Before proceeding with the manufacture, I suggest conducting a short excursion into the history of this aircraft. An airship is a controlled balloon. The first airship took off on September 24, 1852 from a racetrack in Paris to a height of 1800 m and covered the 27-kilometer route to Elancourt at a speed of about 9 km / h. On August 9, 1884, Captain Charles Renard and captain Arthur Krebs overcame Chalet-Meudon A 7.6-kilometer route on the La France airship at a speed of almost 20 km / h (5.5 m / s). It was the first airship to have an electric motor as a drive (the previous one was a steam installation). At the beginning of the 20th century in Germany, Ferdinand von Zeppelin (1838–1917) built a new type of airship - Luftschiff-Zeppelin 1. Instead of a gas-blown shell, which kept its shape, he used a frame covered with an impregnated fabric. Thanks to this, the airship received a solid structure. The first real airship had a length of 126.8 m and a diameter of 11.6 m. It was driven by two 5 kW Daimler internal combustion engines. On July 2, 1900 at 20:00 he got up with 5 people and 350 kg of ballast, after which he made an 18-minute flight from Friedrichshafen to Lake Constance. Already in the second test, he reached a speed of about 27 km / h.

Now let's go over the technical characteristics:

Size: 2.30 x 0.64 m (92 x 25.6 ")

Volume: 0.5 m3

Engine: TURNIGY 2211, 2300 kV

Stroke: Hobbyking XC-10A with reverse

Screw: three-blade 5x3

Battery: 2S 25C 950 mAh

Inspired by the construction seen, a copy of the observation airship on a scale of 1: 7 during the First World War, the author wanted to build a small maneuverable airship for hall flights, capable of carrying a small camera on board.

Shell

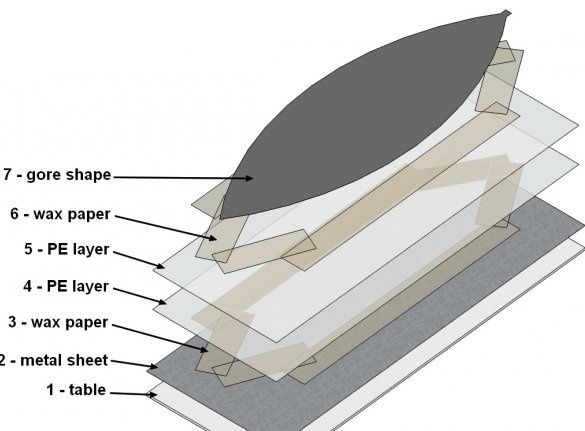

Already having a not very successful experience with foil polyethylene, it was decided to use ordinary polyethylene with a thickness of 70 microns for the cylinder. First, the author checked the retention of helium with several available samples of polyethylene. One of them, with a thickness of 70 microns, had the best retention with a suitable weight to create a not too large shell. The disadvantages of the polyethylene film are less good helium retention compared to the polyurethane film and lower strength. But it is very cheap and easily soldered.To make a shell, you need to put such a sandwich on a table or any other flat surface:

- a metal sheet

- wax paper

- two layers of polyethylene

- wax paper

- pattern

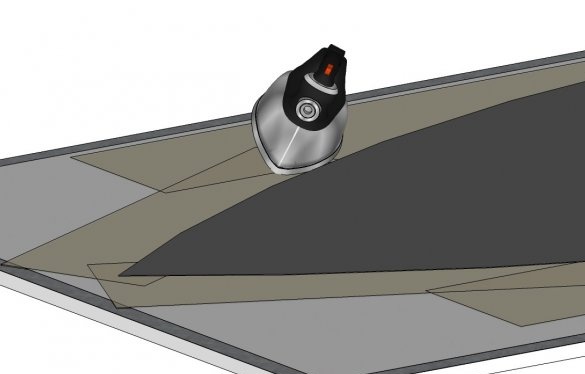

The iron is held along the pattern along the film edge, at an angle of about 45 degrees.

The author used some thick paper as a pattern. Having some experience in such a design from myself, I can say that for these purposes it is better to use a thin 2.5-3 mm fiberboard, this material is quite cheap, 2 bucks per sheet 2440x1220. Especially if the plans are experiments with different films or the need for multiple repeatability.

From the first time, everything may not work, practice before welding on the scraps of the film that you will be soldering. With the right joint, a uniform strong seam should form, and the excess film should be cut off from soldering by itself.

The finished balloon is filled with helium, which can be purchased at offices that decorate rooms for the holidays. The shank, through which the shell is filled, is wrapped several times and clamped.

Tail

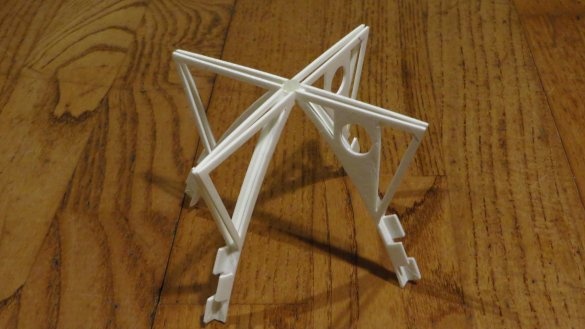

The tail unit is made of two main parts - the mount printed on a 3D printer and the tail unit made of sheet foam (in the original 3 mm Depron, we have a ceiling, a substrate for the laminate), which is attached to these mounts. You can download the print files at the end of the article, however, such a simple design is easy to make with your hands, without any printers.

The rudders and heights are controlled by nine gram servos. The rudder planes are reinforced with carbon rods.

Engine

The engine nacelle consists of two plastic rings interconnected by carbon rods. The details are again printed, but it is also easy to make them yourself and connect, for example, with bamboo skewers. The gondola itself is attached to the shell with two carbon rods with ordinary scotch tape, you can tear off scotch tape from polyethylene unless with the polyethylene itself.

Pieces of heat-shrink tubing are put on the edges of the rods, according to the author this prevents the shell from penetrating when the motor unit hits the ground.

To control the engine, a small ten ampere speed regulator with reverse was used, allowing the airship to go in reverse. Since the task of creating lift in this aircraft is not assigned to the engine, such power is more than enough. Servo drives are connected to the receiver through a lightweight twin extension cord, in which only 2 power wires are left, supplying both servos and 2 signal wires, for each machine. From myself, I can say that this is probably one of those few models that the home-made engine, rewound from the engine from the CD drive, is suitable for.

Video flight demonstration:

Here is such an unusual model can be made from ordinary polyethylene.

You can download everything you need here.