Hello everyone, today I would like to tell you about the next manual work that I liked, well, and I hope you will like it. Handmade knives have always fascinated me. They have a soul, and not just stamping. On the Internet a lot of samples and types of knives, this article is one of. I hope with each of my work I will become better, but for now I admire other people's work.

Steel 95 × 18 is suitable for the manufacture of knives for hunting and tourism, but such knives do not like the transverse load on a break. Such steel contains 1% carbon and 12% chromium, i.e. steel is not subject to corrosion and does not require special care conditions. Knives made of this steel are very quickly and easily sharpened, you can easily correct a knife in the steppe against a stone, which is why many hunters like it. For my convenience, I usually make knife blanks in the form of plates of different thicknesses or almost ready-made knives that just need to be peeled off the ear.

Need a tool

- Ushm

- Dremel

- Billet steel

- Grinder

- Sandpaper Ribbon Set

For the knife of this article, the master took the finished steel plate 92 × 18. The author polished the plane, then applied the template to the plate. Now the next stage is the jewelery work of the ushm. When working with ears, we do not allow the metal to get very hot, but if the workpiece is not thermally processed, that is, it is not hardened and tempered, then there is no particular need to steam it.

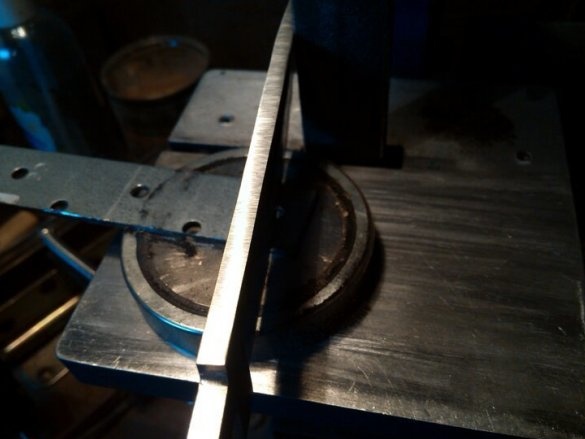

Now the author proceeds to the formation of a wedge on his device, in order to limit the grinder tape, the author sets the crimp to the desired distance and proceeds to the wedge. Cool deviceI have it, only metal. Well, what the author did in my opinion is even nothing. The author forms a wedge on the Grinder, if there is no grinder, you can use the grinder. Now the author polishes everything, changing the grain from coarse to 1000ki, now everything is like a mirror.

Now the next stage, the author proceeds to the hilt. For the handle of the knife, the author took an African ebony and a Brazil nut, and for spacers and guards - a piece of stainless steel. Cutting pieces of wood and metal that are necessary in size.

Having adjusted all the details, the author drilled holes in the center of the bar and adjusted everything to its place, upsets the entire bay with glue and sent it under the fixture, having pulled everything well, leave it to dry.After the glue has dried, the author polishes the desired shape on the grinder or dozes off at all, which is convenient for anyone.

Well, that’s all, the knife is very easy to manufacture and looks very much nothing in general, thank you for your attention.

A couple of works by the Author