Having little experience in woodworking and access to a carpentry workshop, the master decided to start making his dream - a semi-acoustic electric guitar. A semi-acoustic guitar is a hollow-body electric guitar.

Tools and materials:

-Red tree;

-Maple;

-A circular saw;

- Jointing machine;

-Rule;

-Pencil;

- Joiner's glue;

-Calipers;

-Drilling machine;

Milling cutter;

-A screwdriver;

-Fasteners;

-Sandpaper;

-Tape grinding machine;

-Hacksaw;

- Clamps;

- Band saw;

-Rasped;

-Grinder;

-Coating;

-Retail;

-Press;

-Nippers;

-Accessories for electric guitars;

- Paint tape;

MDF;

Step One: Design and Templates

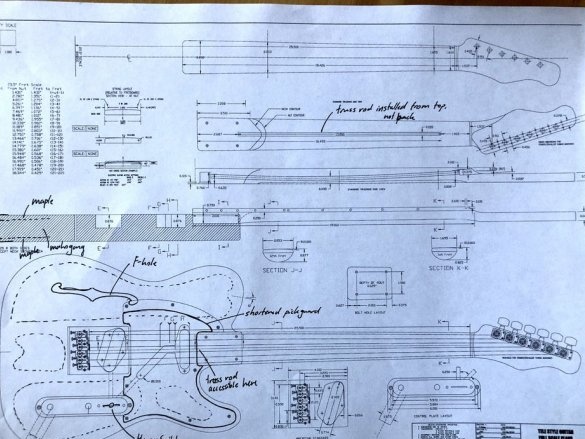

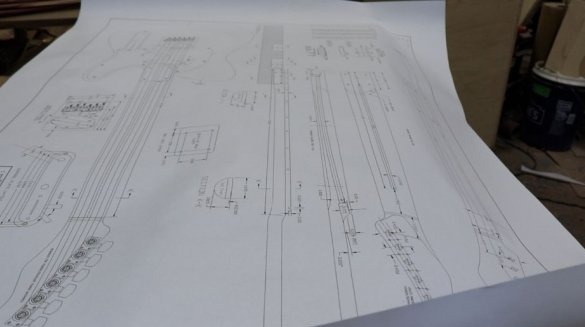

First, the master made a drawing of the guitar and chose the material for the guitar. According to the plan of the master, the deck will be made of mahogany with maple overlays. The fingerboard and head are also made of maple.

Before starting to process wood, the master makes a template from MDF. Prints on paper template. Sticks on MDF. Cuts out.

Templates can be downloaded below.

Tele-Style_Full-Std_TR.pdf

Normal Body Template.pdf

Fender Telecaster-Thinline-Bodies.pdf-

Step two: deck - middle part

As mentioned earlier, the electric guitar, which makes the master semi-acoustic. This means that the deck of such a guitar is hollow. Template master cuts a cavity in a mahogany board. Niche in which it will be installed electronics Wraps with a copper tape.

Step Three: Upper and Lower Deck

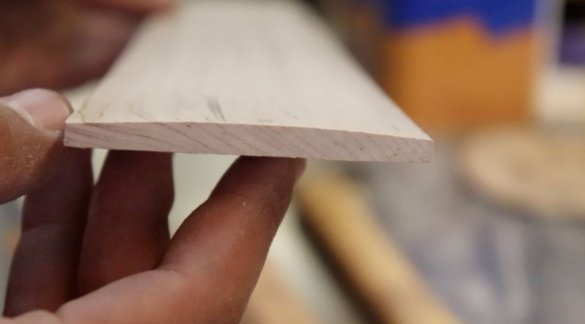

Further, the master cuts the upper, lower deck and overlay. He makes them from maple by pre-processing the board on a planer and sawing it into thin blanks.

Now you can glue the upper and lower deck.

Step Four: Processing

After gluing, the master mills and polishes the workpiece.

Makes a cutout to set the neck. Drills holes for installing the holder. Handles the edges.

Step Five: Vulture

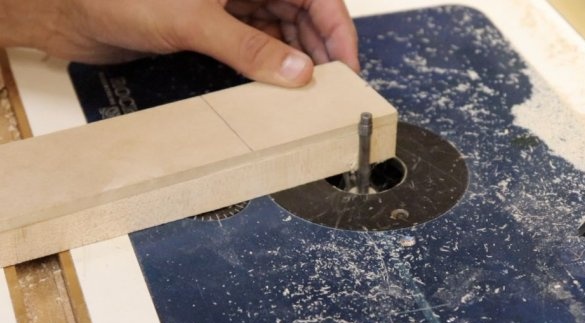

To make the pads, the master makes a template. The maple board is placed in the template and makes slits for the sills. The markup for them is done using a special program.

Then you need to grind the pad with a sanding block.This is the top of the neck.

The lower part is done in conjunction with the head. A notch is made along the neck and a rod is installed.

Holes for pegs are drilled in the head.

Glues the fingerboard.

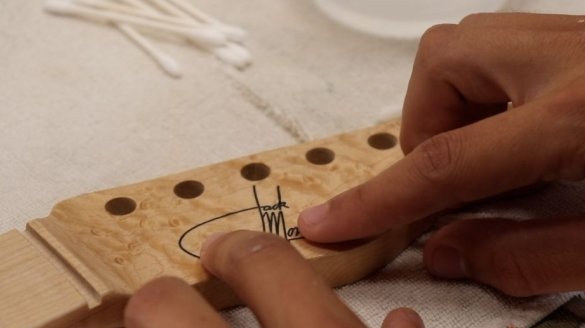

After gluing, it processes the bar, giving it the desired shape. After grinding, points were glued.

Step Six: Finish

When the parts were ready, the master coated them. First, several layers of stain with grinding between the layers. Then several layers of polished polyurethane varnish. The last coat is not sanded.

Seventh step: electric guitar accessories

Then the wizard installs the components. It is clear that he did not make them himself, but bought them.

Sets sills and strings.

Stretches the strings.

Step Eight: Adjusting the Nut

Then the master removes the strings and polishes the edges of the sills.

Checks the height of the pegs.

Sticks masking tape between the pegs. Using a sanding block, it aligns the pegs in height. Then it grinds at the edge pegs. This is necessary to reduce the area of contact between the strings and the splitting.

Now you can set the strings in place and tune the guitar.

All is ready.

The whole process of making a semi-acoustic electric guitar, as well as the game on it, can be seen on the video.