My wife bought an iron made in China using American technology. I worked for three months and stopped turning on. I decided to figure out what was going on and began to study all of his data. And I was very surprised when I read on the plate that its power is 2000-2200W. Where so much? This is the current under 10A, it turns out that when the wife strokes the linen she also heats the room. Yes, we already have hot batteries and the housing and communal services are tearing at the meter maximum in any weather.

Come on, something I'm not talking about. In general, I dismantled the iron with the nerves, the fact is that almost all the parts are latched and they break in infection when disassembled. The reason for the failure was immediately determined - there is no connection in the temperature sensor that turns on the heater. I washed it with alcohol, but there was still no contact, even with the mechanical regulator turned as much as possible. It is not clear what material these contacts are made of, well, certainly not of silver. In short, he mechanically cleaned with a scalpel and contact appeared. The reason for this malfunction is that with such an iron power, the heater turns off frequently, as the temperature is reached very quickly. And the frequent inclusion of the heater is due to the fact that the mass of the heated part is not large and is made of light metal of unknown origin. That is, the heat quickly leaves. Yes, I forgot to say that there is still water to create steam, it also cools.

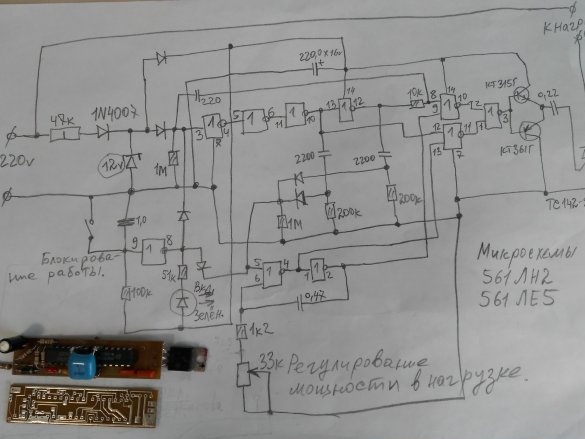

In general, I decided to assemble a power regulator for the iron. The appearance will be similar to the previously published homemade, only instead of the fixed settings I will set the potentiometer. The scheme is grandfather, but very reliable.

Its main advantages are:

1. There are no failures and disruptions of synchronization when turned on.

2. Very low current consumption.

3. It works in a wide temperature range.

4. Can control any power triac.

5. Accessible parts list.

Sponsor articles online store where you can world stamps to buy.