It would seem that just recently a “Ilyich’s bulb” reigned in our homes, then halogen (which worked with overheating, that is, issued a greater luminous flux) lamps appeared. Then, halogen lamps were replaced by energy-saving lamps, which significantly reduced the cost of electricity for lighting a similar area. And finally - the LEDs! How could one have supposed 10-20 years ago that a tiny crystalline semiconductor could illuminate large spaces, while consuming only a few watts? We will not focus on the principles of operation of this device, we will only say that it was invented (may all Russians be proud!) By our compatriot O.V. Losev.

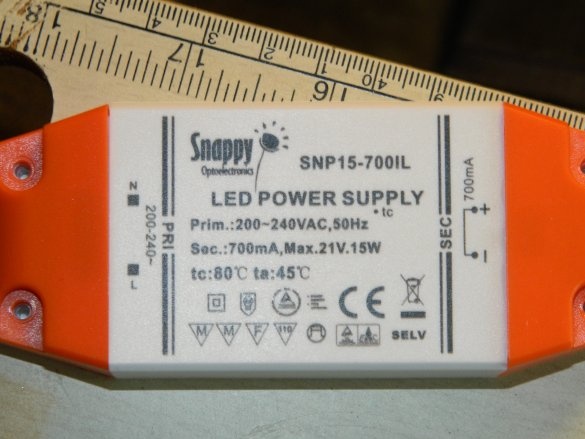

A little background to this process. To power the LEDs, a current source (PWM driver) or any other that produces direct current is used. Using a PWM driver, which produces 700 mA, will provide this circuit and 5 series-connected LEDs with a power of about 10-12 W, which corresponds to 1000-1200 lumens of light output. This is enough to illuminate the working area of the table. Then the routine work was to unravel everything.

In the built-in spots, which stood on the visor of the kitchen and illuminated the working space, there were 20 W halogens - 5 pcs. (100 watts!). I have long remade them into LEDs, but they were very hot. I decided to leave the old reliable driver and redo the spots - put other radiators.

After the assembly was completed, it turned out that the radiators did not fulfill their functions, i.e. cooling is not enough. Plus, the luminous flux decreased due to frosted glass (about 15%).

I also flew with radiators - ordinary aluminum plate. To prevent the glass from touching the LED in the lamp, the plates were cut and “concave” inward.

Measurements of the temperature on the radiator showed that it was gradually growing, and the luminous flux dropped to 200-210 lm per point. But this was enough to illuminate the desktop. The temperature increased to 55º-58ºС (and grew further), and this was already fraught.

As a result, I had to abandon the glass on the lamps. It was necessary to put normal radiators.

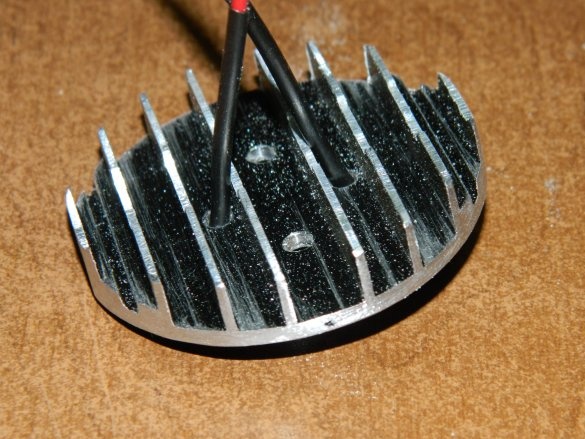

In the zashashnik I had BLA099-50 radiators. If they are slightly undermined, then they will calmly stand in the built-in spots.

Armed with a grinder, I joined in the work. Turning the radiators to the size of the spots, I started fixing them.

The central hole was used for fastening the “spots” of the spots due to the elastic plates. I had to drill holes on the sides and fix the radiators on them.

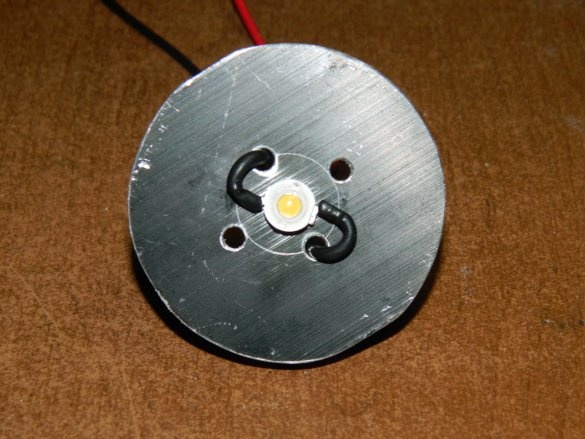

The lateral hole served for the conclusions of the supply wires. LEDs stood on the same mounting plates Ø15 mm and were mounted on hot-melt adhesive. After the glue has dried (12-24 hours), the lead wires are soldered.

After all the radio engineering and mechanical work, he turned on the lamps and after an hour measured the temperature on the radiator - it was 33 ° C. These assemblies will last me a long time.