In this article, the author of the YouTube channel "StoDel_56" will tell you how he made a special drill for making wooden plugs.

Materials

- Old wood drill bit

- Boards

- Aerosol varnish

- Sandpaper.

Instruments, used by the author.

— Screwdriver

— A circular saw

- Lathe, drilling machines

— Forstner Drills

- Grinder

— Clamps, marker, chisels

— Electronic caliper.

Manufacturing process.

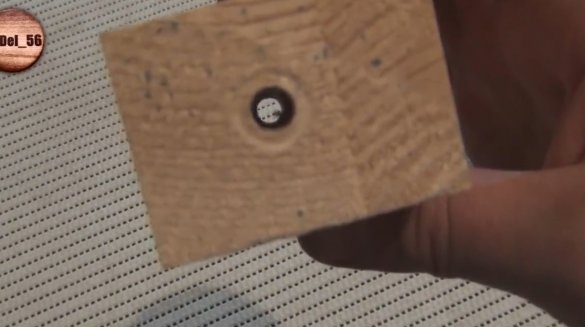

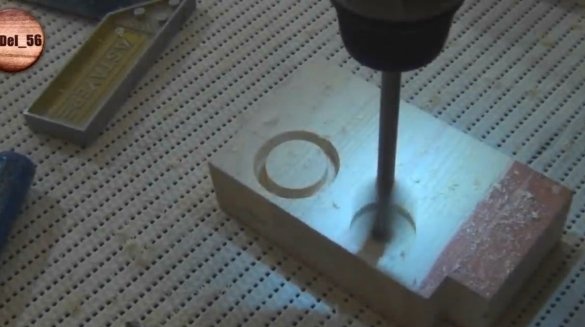

So, the first thing the master chose a suitable, but already old pen drill with a blade width of 41 mm. He also drilled a hole in the bar along the diameter of the shank.

The distance that the master needs to get between future incisors is 30 mm. On both sides of the scapula he marked the markings, inserted the drill into the block, and aligned it with the table.

Now you need to cut off the centering point on the grinder, it will no longer be useful.

Next, two slots are made for marking, and the drill must be turned upside down.

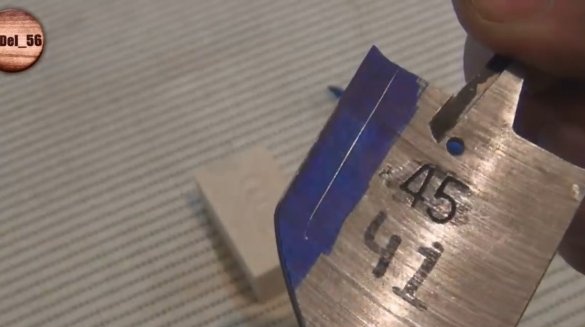

The distance between the cutters was slightly less than necessary, 29.2 mm

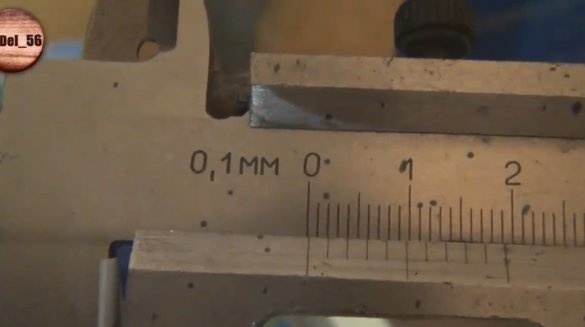

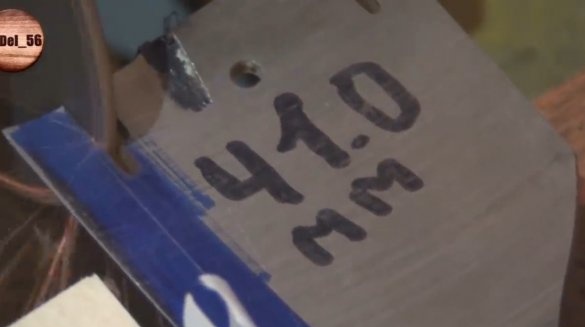

To increase the distance, you need to slide the guide near the machine by 0.3 mm, however, it will be difficult to do it manually. Therefore, the author uses a fairly simple technique, he folds a sheet of paper in half, and has such a lining between the guide and the bar. As a result, the resulting size was 29.8 mm. This is ideal for the task.

Excess metal is also removed from the center of the blade.

So, here's a little bit of a drill from the master.

He will produce enough plugs, so he drills several holes in the boards at once.

To remove the plugs from the board, the master removes a small amount of material on a circular saw.

To process all the workpieces quickly and beautifully, he grinds a small block on a lathe, and makes a hole in it along the diameter of the stub leg.

Plugs sit indevice very tight, and to make them easy to reach, the author drills a hole at an angle.

Everything is ready, the workpieces are installed on a lathe, and processed using a grinding disc and grinder.

After processing, the workpiece is simply knocked out on the back with a long bit or a screwdriver.

As a result, in less than half an hour, the master turned out a whole hill of such products.

In an unnecessary bar, the author drilled a test landing hole with a Forstner drill with a diameter of 30 mm. As you can see, everything is perfect.

Now the master paints all the blanks with spray paint.

After the first coat of varnish has dried, sanding is done manually with sandpaper, and a second coat of varnish is applied.

This drill has a very high accuracy, and it has no beats. The author achieved this when turning, when he used a guide bar, and turned the drill in it.

Both the outer diameter of the stub leg and the distance between the cutters was 29.8 mm.

It is also possible to make small cylinders to which decorative overlays are glued.

Of course, some may object that such plugs can easily be purchased at the store. However, the master made 100 such plugs in a short time, and one costs about 25 rubles. The savings amounted to 2500.

You can also make them any desired type of wood, and the required diameters.

I thank the author for a simple but useful tool for the workshop, and the technology for the production of plugs!

All good mood, good luck, and interesting ideas!

Author video can be found here.