Surely those of you who work with metal often face the need to bend a steel square, strip, and other metal rolling.

In this article, the author of the Be Creative YouTube channel will tell you how he made one of the simplest devices to solve these problems.

This homemade product is extremely easy to manufacture, requires a minimum of tools, and takes a few minutes. And as materials - almost any trim from thick metal is suitable. Yes, on this site there are more than a dozen different bending devices, they have much more functionality, but they are very difficult to manufacture.

Materials

- Steel plates 10 mm thick

- steel strip

- M10 socket head screws with countersunk head

- Screws M8 with hexagon and round head

- Engine oil or grease WD-40.

Instruments, used by the author.

— Electronic caliper

— Geyfer capture

— Screwdriver

- Drilling machine, vise

— Bulgariangrinding wheel

— Tap, drill bits for metal, countersink

- Marker, core, hex keys.

Manufacturing process.

First of all, the master marks the centers of two future holes on a steel plate 50X90X10 mm at a distance of 13 mm from the edge.

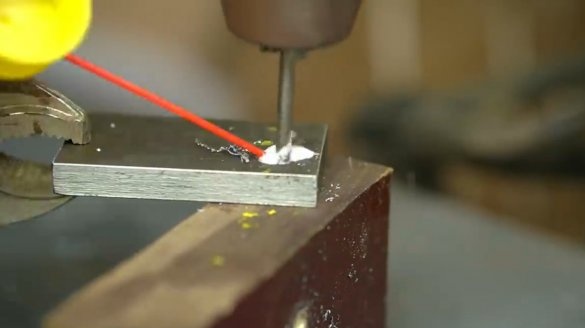

Clamping the workpiece with a geyser grip drills two through holes with the mandatory use of lubricant (for example, WD-40).

A steel strip 10X25 mm and a length of about 50 cm will be used as a handle. He finds a central line on it, marking it with a caliper on both sides.

Center the plate relative to the handle and mark the holes. Then performs drilling using grease.

Then, M10 thread is cut into the handle holes.

On one side of the plate, the holes are countersunk under countersunk heads of the clamping screws.

Now the plate is screwed with M10 screws for a hexagon with countersunk head.

At the next stage, the master marked four holes on the counter plate, drilled them, and cut the M8 thread into them. He also drilled mating holes for screws in the first plate.

All details are almost ready, the author connects them with four screws, leaving a gap of several mm between the plates.

For the last adjustment of the tool, he fixes a steel strip in a vice, puts on it device, and tightens the screws.

Then the author makes a trial bend. The angle of the pressure plate abuts against a vice sponge. He marks with a marker a layer of metal to be removed.

The presser is fixed in a vice, and excess material is removed using a grinder with a grinding wheel.

Now nothing prevents bending the steel strip at an angle of 90 degrees with a minimum radius.

The next test will be a steel square 10X10 mm. The fixture is put on him and the screws are tightened.

After performing the bending operation, the screws are loosened, the device is removed.

Such results are provided by such a simple device! They can also try to bend the pipe, but it will have to be densely filled with sand, so as not to get a “fracture” at the bend. Of course, a small drawback and inconvenience is the constant need to unscrew and tighten the clamping screws. For optimization, you can attach four eccentric clamps, then everything will be much more convenient and faster.

Also, if you fix a pipe in a vice near the workpiece, then the bend of the workpiece can be obtained with a large radius.

I thank the author for the idea of a simple but very useful tool for the workshop!

All good mood, good luck, and interesting ideas!

Author video can be found here.