Who removed the insulation from the wires knows what a chore this is. Yes, there are wires where you can cut the insulation, pull on it or the core, and the insulation is removed itself. But with most wires, it needs to be cut along its entire length. The master came up with and made a tool that “dissolves” the insulation along the entire length of the wire.

Tools and materials:

-A metal sheet;

-Threaded studs;

-Nuts and washers;

- Bearing with bearing;

-A pen;

-USHM;

-Vise;

-Drill;

-Pipe cutter;

-Conical gears;

Step One: Metal Plates

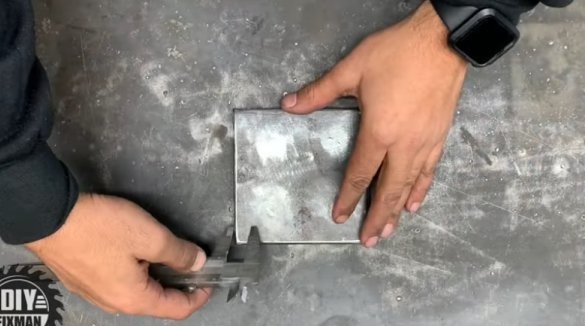

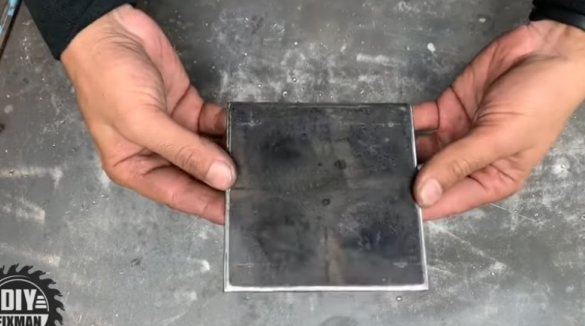

The craftsman carves two square metal plates. The size of the side of the square is equal to the length of the bearing support + 1-2 centimeters on each side.

At the edges of the plates, the master marks and drills holes for fixing the supports. In the center of one of the plates (top) drills a hole for mounting the cutter.

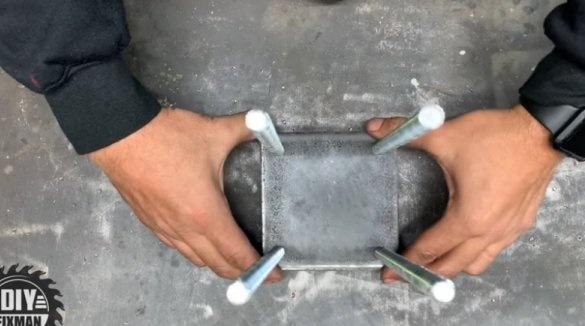

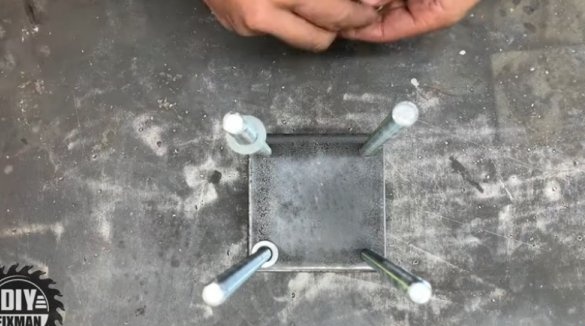

Installs studs with screwed nuts into the holes in the bottom plate.

Step Two: Broach

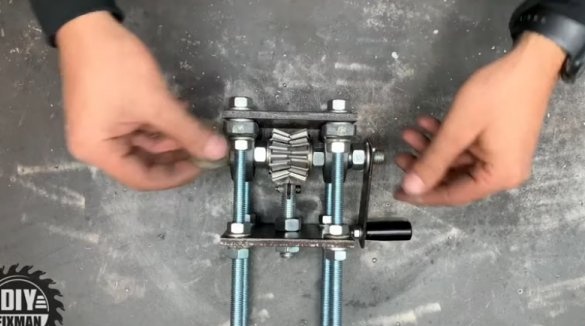

For broaching, the master took two bevel gears. Installs them on the thread and fixes them with nuts.

Installs the structure in the supports. The supports are mounted on studs and secured with nuts.

Step Three: Cutter

Now you need to make a cutter. To fix it, the master takes a threaded rod. At the end of the stud makes a cut.

A cutter removes from an old pipe cutter.

A hole is drilled in a hairpin. Sets the cutter. The cutter should turn on the shaft-bolt.

Screws a hairpin with a cutter into the central hole of the upper plate.

Screws the nuts onto the studs. Sets the top plate. Fixes it with nuts.

The excess part of the stud is cut off.

Step Four: Pen

To actuate the device you need to install the handle. The master cuts out a metal plate. Drills in it, at the ends of the hole. In one hole secures the handle, the second hole for the drive shaft.

The device is ready and the master is testing it. Fastens in a vice. Adjusts the clearance between the cutter and the gears. This distance is adjustable depending on the diameter of the wire.

Checks the operation of the device on a wire with soft insulation.

Now testing the device on hard insulation.

The master is satisfied with the test results, the device copes with its work perfectly.

The whole process of manufacturing this device can be seen in the video.