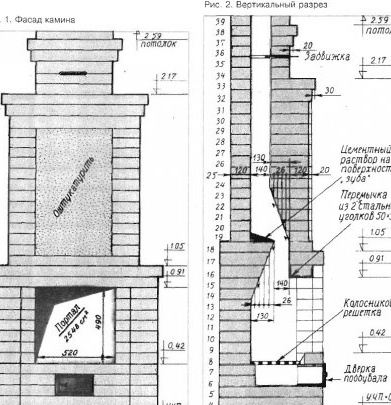

Fig. 1 Facade of a country fireplace; Fig. 2 Vertical section of a country fireplace.

In summer cottages and garden houses, the sizes of rooms are usually small, therefore it is advisable to make a fireplace small and place it in one of the corners of the room. The design of the corner fireplace with a facade, a vertical section and with all orders is attached in figures 1-7.

There are many other options for the design and placement of fireplaces. It can be located in the middle of the room, and against the wall. There may be collapsible light fireplaces that are used in the cold season, and they are cleaned for the warm period.

The proposed type of corner fireplace is designed for a room with an area of 12.5-13.0 m2 with adjoining it to brick walls. For a room with an area of 15-16 m2, the height of the portal needs to be increased by 1-2 rows of bricks, because the size of the portal depends on the area of the room in which the fireplace is located.

Need for brick on construction country fireplace is 415-420 pcs.

Foundation

The foundation is laid out on a good foundation from strong materials - rubble stone, limestone, iron-brick or concrete. In wet soils, brick-iron should be used (ordinary brick from dampness can be destroyed), rubble stone or concrete. The dimensions of the foundation in the plan should be 5 cm wider than the base of the fireplace in all directions.

According to the size of the foundation, a hole is dug, the depth of which depends on the density of the soil and the hydrogeological conditions of the construction site.

The depth of the foundation under the fireplace should not be higher than the depth of the foundation of the house itself. The bottom of the pit is carefully leveled, and in case of weak soil it is compacted with flooding of crushed stone.

The foundation is laid on a cement mortar with a composition of 1: 3-1: 6. To save cement, complex or mixed solutions are used in a ratio of 1: 2: 8 or 1: 1: 9, that is, up to 2 parts of lime dough and 8-9 parts of sand are taken for 1 part of cement.

Foundation laying is completed below the level of a clean floor by 140-150 mm (into 2 rows of brickwork). The surface of the foundation is checked for horizontal (preferably level) and leveled with cement mortar. Then they put a row of bricks, and on it - a waterproofing of 2 layers of roofing material. On top of the waterproofing, another row of bricks is laid, which almost reaches the floor level. Above lay the fireplace itself.

The foundation should be 50 mm from the foundation of the house. The gap is covered with sand.

Work and materials

The thickness of the joints should be no more than 3-5 mm, and when laying from refractory and refractory bricks - 3 mm. The thickness of the joints of the pipe masonry on lime and complex mortar is allowed up to 10 mm.

It is strictly forbidden to grease the fireboxes and smoke channels with clay mortar. They are mopped (wiped) with a sponge brush or a wet rag. All turns and angles must be rounded off, and make the narrowing or extension smooth - this increases traction.

The grate is placed below the furnace hole for 1-2 rows of masonry with a gap between the grate and the masonry around the entire perimeter of at least 5 mm.

Normally burnt brick is pricked without a notch, slightly burnt with a preliminary notch up to 5 mm deep along the entire chip contour:

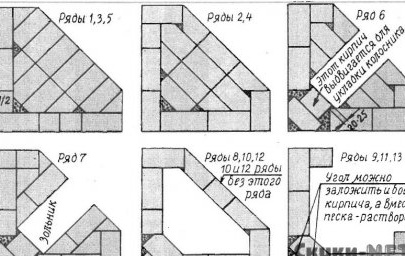

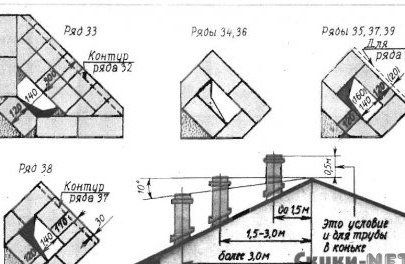

Fig. 3 Laying bricks of a country fireplace in rows.

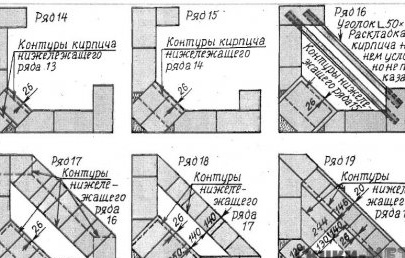

Fig. 4 Laying bricks of a country fireplace in rows. (Continued)

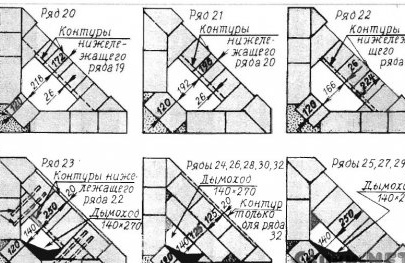

Fig. 5 Laying bricks of a country fireplace in rows. (Continued)

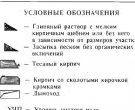

Fig. 6 End of construction of a country fireplace.

The brick is previously laid out dry (at the rate of 3-5 mm per seam). Then the bricks, one at a time, moistened in water, are placed on the clay mortar in place. Red brick is moistened in water for 5-10 seconds (until air bubbles are released). Scarlet brick cannot be wetted — it is soaking and falling apart. Refractory brick is only rinsed.

Refractory bricks are placed on a solution of refractory clay without admixture of sand.

Instead, finely chopped fireclay is introduced into the solution in a 1: 1 ratio.

The thickness of the fluff is at least 260 mm with the insulation of wooden structures with sheet asbestos. Wooden rafters and laths must be separated from the outer surfaces of the outer pipes by at least 130 mm (half a brick).

For fastening the frames of the blower doors, strip steel 15–20 x 2-3 mm is used. Securing the doors with chimney wire is impractical.

After laying, the fireplace should be well dried. During the drying process, all valves and doors must be open 24 hours a day. It takes about 10-12 days to dry.

! It is not allowed to use silicate and perforated bricks for laying foci and chimneys.

1) the cross-sectional area of the chimney should be at a pipe height of 6 m in size

14 x 27 cm, the ratio of its section to the area of the portal was 1: 3-1: 10. The cross section of the chimney is best done in size 27 x 27 cm;

2) the size of the portal depends on the size of the room and is usually 1/50 of its area. The large portal will supercool the room and form drafts, the small one will not produce enough heat;

3) when the fireplace is ignited, until the chimney warms up, there is a clogging of smoke in the room. To avoid this, the chimney must be heated by burning a bundle from a newspaper or by providing artificial draft through a portable household fan;

4) to regulate combustion and eliminate clogging of smoke into the room, it is desirable to make a shutter made of roofing iron or duralumin or a decorative grille.

Due to the fact that the masonry, the fireplace comes with a wall thickness of half a brick and on a weak clay mortar, the dressing of the joints must be ensured by min 1/4 of the brick.

Pay special attention to the thoroughness of the tees and surface treatment of the brick for laying out the “tooth” and the areas in contact with the fire, which is achieved initially with a pickaxe, then polished with corundum stone or hard brick (brick on brick). The processed brick can be pre-wetted - it becomes somewhat softer.

The ash pan size is specified locally depending on the size and type of the grate and the blower door.

The rear wall of the firebox from 1 / 3-1 / 2 of the height should form an inclined plane. The smoother and smoother the inner walls of the firebox, the more heat is generated.

To increase the heat transfer of the firebox, its rear and side walls are lined with 8-10 mm thick bronze sheets.

The height of the chimney depends on its location with respect to the roof ridge (see Fig. 6).

Brick pipes above the roof, as well as 50-100 mm below the roof, are plastered with cement mortar.

Recommendations for the preparation of solutions.

To prepare the solution, sand is sieved through a sieve with cells from 1 x 1 to 1.5 x 1.5 mm. Clay is soaked for 1-2 days and filtered through a sieve with a 3x3 mm cell.

Pour a layer of sand into the box, then pour the filtered clay, fill it with a second layer of sand and mix everything thoroughly. Such a solution is considered good when, when rubbing it between the fingers, a rough layer of grains of sand is felt, and not a slippery film with individual grains of sand in it. A normal solution looks like thick sour cream, it easily slides from a steel shovel, and does not spread on it. The solution is prepared at least 1-2 days before use.

The masonry requires an amount of mortar equal to 1 / 10-1 / 13 of the external volume of the fireplace. On average, it is believed that for 100 bricks, you need to take 2.0-2.3 buckets of clay and 1.5-2.0 buckets of sand.

Clay solutions - solutions of low grades (their strength is 4-8 kg / cm2). To increase strength, add 100-250 g of table salt or about 0.75-liter can of cement to 1 bucket of solution. The salt is pre-dissolved in a small amount of water and only then added to the solution. Cement is shut with water until a liquid creamy mass is obtained, which is poured into the solution.

When compiling a lime mortar, 0.5-5.0 volume parts of sifted sand (usually 2-3 parts) are taken per 1 volume part of the lime dough.

A complex solution usually consists of 1 part cement, 1–3 parts of lime paste and 6–15 parts of sand.

For plastering a fireplace, the following solutions are recommended:

1) clay, lime dough, sand, asbestos - taken in a ratio of 1: 1: 2: 0.1 (parts by volume);

2) clay, sand, cement, asbestos (1: 2: 1: 0,1);

3) gypsum, lime dough, sand, asbestos (1: 2: 1: 0.2).

Solutions are prepared as follows. Sieve all dry materials through a clean sieve. Then they make a dry mixture and mix everything thoroughly.

Having mixed thick clay milk (or milk of lime), mix it well with a dry mixture of other components and get a stucco solution.

For spraying, water is added to the solution until a creamy mass is obtained. A second layer of soil is applied to freshly applied spray, level it and rub it.

Solutions with gypsum should be put into operation no more than 4-5 minutes after its preparation.

After drying the plaster and fixing possible cracks and irregularities, the walls are painted (bleached) with milk of lime and salt (100 g of salt are taken per 1 bucket of milk of lime).

Good luck to you, dear craftsmen!