Furnace design

There is an opening in the lid of the oil tank for primary fuel filling, ignition and cleaning. It is also used as a blower: the burning intensity can be changed using the cap. During the furnace, the lower part of the burner tube is red-hot. Along the pipe, which pumps heated air into the garage, a copper pipe with a diameter of 8 mm is laid under the insulation layer. A 18 liter tank is installed in the garage. From it, the oil is sent by gravity to the dispenser (“drinking bowl”). Using a drinker, you can determine the level of remaining oil in the burner. There is a valve on the tank that regulates the oil supply. Fuel consumption is from 0.5 to 1.5 l / h, depending on the intensity of combustion and oil supply. Ignition is carried out using a blowtorch or torch. The oil lights up after 2-3 minutes.

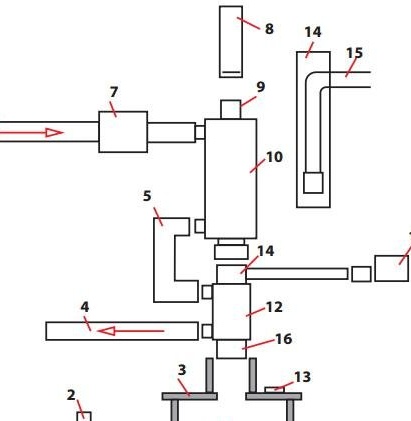

Design drawing:

1 - capacity for oil (d 240 mm, h = 120 mm); 2 - "drinking bowl" (water pipe d 20 mm); 3 - container lid (steel, 300x300x10 mm); 4-6 - pipes for air circulation (aluminum corrugated sheet, d 90-100 mm); 7 - fan for air supply; 8 - chimney (d 110 mm, L = 3 m - not less); 9 - thick-walled pipe (d 108 mm, L = 110 cm); 10 - heat exchanger No. 1 (water pipe d 150 mm, the ends are welded); 11 - burner fan; 12 - heat exchanger No. 2; 13 - hole with a lid; 14 - thick-walled pipe (d 108 mm, L = 65 cm), 15 - water pipe d 32 mm; 16 - bottom of the burner (coupling d 32 mm, welded from below, in the center - hole d 5 mm, on the sides - 7 holes d 8 mm

The furnace does not smoke; soot is also not observed during the combustion. Using the damper located in the upper part of the heat exchanger, it is possible to regulate the burning rate and, if necessary, completely extinguish the furnace.