If you want to try to make a solenoid motor yourself home conditions, then this scripture is especially for you.

We also suggest that you watch a step-by-step video before starting work, so that you can more clearly understand how and what is being done.

To make the engine we need:

- A big wheel from a toy car;

- a pen;

- a bolt or nail no thicker than the diameter of the handle;

- wine cork;

- a few screws;

- paper clips;

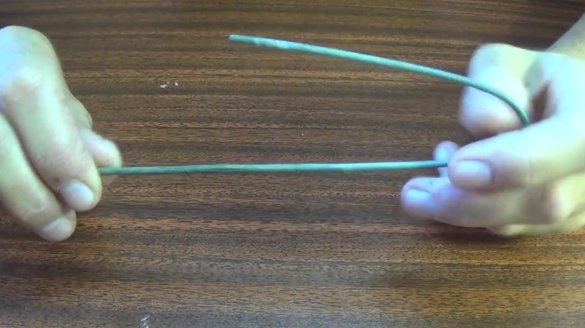

- steel wire with a diameter of 3.8 mm and a diameter of 1.3 mm;

- 1 meter of ordinary electric wire;

- copper wire in insulation with a diameter of 0.4 mm;

- 12 volt power supply to power our engine;

- a wooden block of arbitrary size, which will serve as the basis for the engine;

- pliers;

- bocares;

- screwdrivers;

- caliper-compass;

- round pliers;

- a hacksaw;

- drill 1.4 and 3.8 mm;

- a hacksaw;

- glue gun;

- screwdriver-drill.

First of all, we need to collect a solarium. To do this, we need a hacksaw, a cork, a caliper and a handle.

We disassemble the handle.

We need to cut a part with a thread from the handle, for this we use a hacksaw blade.

Next, measure from the handle body 35mm and cut them with a hacksaw.

Trim the ends and remove the burrs with a file.

The next step from the cork we make small discs with a thickness of 5 mm.

In the center of each disk, we make a hole with a diameter equal to the outer diameter of our handle.

Now, using hot-melt glue, we glue our boards on different ends of the handle. We got the foundation.

We proceed to winding the coil, for this we take a 0.4 mm wire and wind 500-600 turns.

The main thing is that all 600 skeins should be in one direction.

Pass the end of the wire through the pancake from the cork.

It is recommended to wind the coil for strength with electrical tape.

Now we turn to the manufacture of the piston. We take a bolt or a nail and cut off the hat with a hacksaw blade.

We make a cut perpendicular and a small through hole.

Now we need to make a connecting rod. To make a connecting rod, we need a 3.8 mm wire.

We need to flatten the wire so that it fits well into the groove on the bolt. In the flattened spot of the bolt, we need to make exactly the same hole of 1.3 mm.

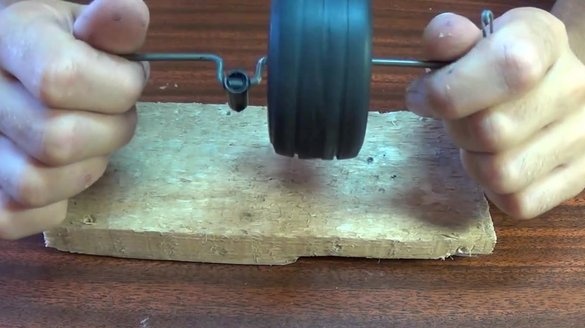

Now you can begin to manufacture the crankshaft. We will need a 3.8 cm diameter steel wire.

You will need to make a “knee” on the third wire often.

In the role of a flywheel, we will use a wheel from a large children's car.

To connect the connecting rod to the crankshaft, we will use the cap from the handle with two holes drilled to each other.

The cap from the handle must be installed on the knee, then the connecting rod will be attached to it.

You can fix our design from pre-made legs. The legs are made of 1.4 mm wire.

Now we need to make contact from a piece of copper sheet.

The tip of the crankshaft needs to be slightly bent, but during rotation it should come in contact with a piece of aluminum.

Now we install the connecting rod, the saltman and try to run.

We connect the wire and plug it into a power outlet to check the operation.