True fishing enthusiasts prefer to make various fishing tackle on their own. A variety of baits are especially popular: poppers, marmysh, etc.

In the video you can see the phased creation of the popper.

[media = https: //www.youtube.com/watch? v = h0A1pVkG2_E]

For work, we need:

- birch bar;

- knife;

- a hacksaw;

- file;

- drill;

- file and sandpaper;

- a pencil;

- nickel-plated wire.

Before you begin to work, we decide which side of the wedge we will have a head, and where is the tail. In that part of the birch whetstone with which we will have the tail, it is necessary to make a refinement. The easiest way to do this is with a knife, cutting off the surplus to the desired size of the block.

After the initial bevel has turned out, with further work we give it the correct shape. With a knife, we correct all the bumps, bringing the tail to the desired state.

After that, you can begin to process the head part. We make a small cut with a hacksaw, after measuring the angle of the bevel. This saw cut will serve as the basis of our future spit.

We smooth out all roughnesses and roughnesses with a file. After that, as a result of processing, an almost finished bait will turn out, which remains to be equipped with the necessary accessories.

The workpiece is being finalized with a file because birch lends itself poorly to knife processing.

Since there will be a lot of sawdust and dust during operation, do not forget to substitute a small container during operation at home, into which all garbage will fall during operation.

After processing, the popper should be smooth.

Now you need to attach a spit in the head to the workpiece. To do this, just hollow it out. You can form a recess with a knife or a boron machine. Bore the recess and make it smooth. To squander a recess, it is best to take a large drill and start scrolling it inside with your hand. And smoothness can give it files and sandpaper.

With a knife we remove the extreme chamfer.

Now on the workpiece you need to make markings for the frame on the abdomen, we do this with a pencil.

On the marked line we make a small cut with a hacksaw.

Now we extend the cut with the file, until the frame freely enters into it, while it must enter fairly tightly.

From nickel-plated wire we make a frame for popper. Insert it into the cut.

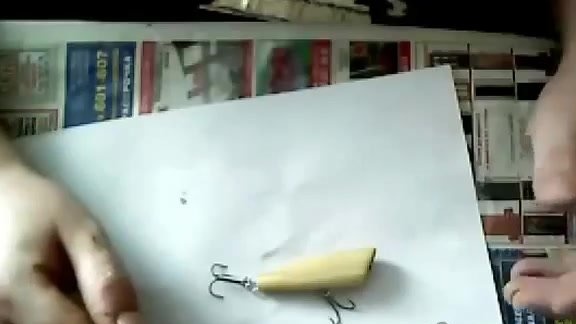

We lay down the initial load and grab the hooks, test the popper. He should stand in the water at an angle, with a recessed tail.

After the tests, we proceed to gluing the cut so that all the parts are fixed in place. We color it and varnish it.

Popper is ready.