If you often do construction and finishing work, then you probably have to very often clean any surfaces. It's no secret that this is done with ordinary sandpaper, which becomes unusable in a very short time. If you compare the price of one leaf of sandpaper and a circle with Velcro, then the price will be completely the same, only the circle has a diameter of 12 centimeters, and the leaf is three times the size of this circle.

Watch a video on how to make three Velcro discs from a sandpaper sheet

To work, we need:

- 1 round disk bought;

- a sandpaper sheet of the standard size;

- double sided tape;

- scissors.

We need a base to which we will attach sandpaper and tape.

Then we take a double-sided tape and cut off a large piece, which is glued to the very center of our circle. Scotch tape must be taken very, very sticky, otherwise it will not hold

Now cut off about 8 small pieces of tape and glue them around the perimeter.

Now remove the protective film from the tape.

We take our sheet of sandpaper and turn it with the rough side to the surface of the table.

In the corner of sandpaper we glue our blank. Be sure to glue it in the corner, otherwise we will have to leave a lot of sandpaper in vain.

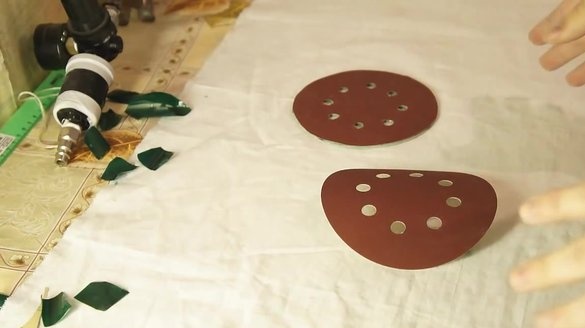

Now we cut out all this business.

The disk is almost ready, the most recent remains - it is to make holes in the disk. To make holes we take a drill and any drill on a tree.

Now we put any piece of wood on the table, put the reverse stroke on the drill and start making holes.

All our grinding disc is ready, now it can be hooked onto a typewriter and used.

This approach has several advantages. Firstly, it’s cheap, and secondly, you don’t have to run to the store if you have run out of round Velcro discs. Thirdly, a disk can be cut out of the sheet if the desired mushroom is not on the counter.

Of the minuses, although he is one, but he is. Disks need to be done do it yourself and spend your time and your energy on it.