All people who have ever soldered and soldered metal products ever know how difficult it is to solder tin to metal. Of course, such acid can always be bought at the store, but it is always easier to do something. do it yourself and understand the process of making certain things than to buy ready-made products in the store.

If you want to try making soldering acid at home, then watch the video

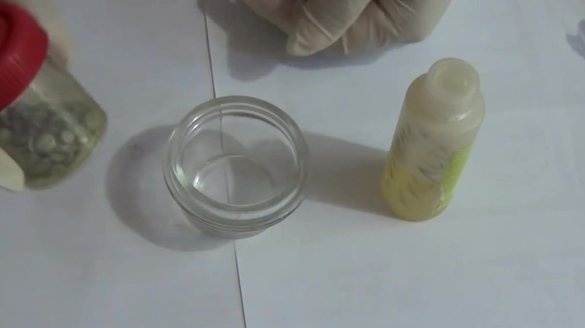

To make soldering acid, we need:

- hydrochloric acid, concentrated;

- zinc in granules or cups from old batteries;

- a jar.

If you did not find zinc in the granules, you can use barrels from old batteries or go to the non-ferrous metal purchase point, there is very often zinc that you can purchase. If you don’t have any unused batteries at your place, and there wasn’t any excess zinc in the non-ferrous metals section, just go around the market, you can often find people selling zinc there.

Soldering acid is obtained when zinc is dissolved in hydrochloric acid at the rate of 412 grams of zinc per 1 liter of hydrochloric acid.

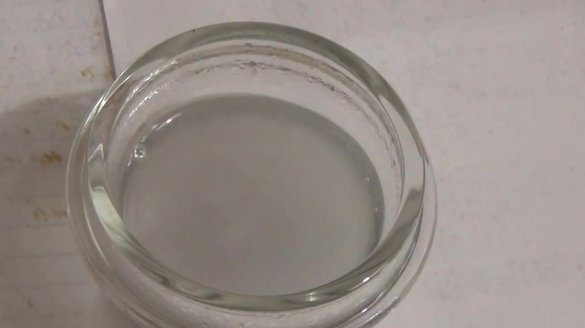

Pour zinc and gently fill everything with hydrochloric acid, but its level should not exceed ¾ of the depth of the dishes. When zinc is completely dissolved, then the dissolution of hydrogen bubbles will cease.

Important! When making soldering acid, always follow safety precautions. Wear safety gloves and eye protection.

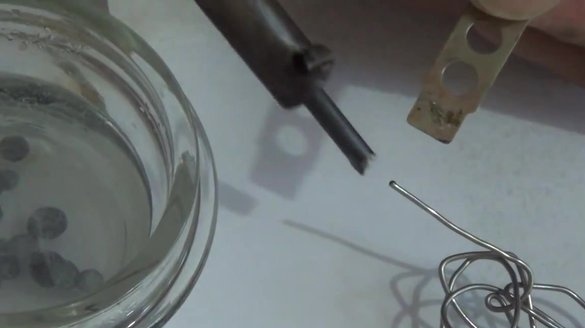

When we fill zinc with hydrochloric acid, we will have a huge number of bubbles and steam. Steam is liquid hydrogen, and bubbles are a reaction in which our zinc is completely dissolved.

The reaction will be quite long, but you have to wait until all the zinc has dissolved.

Wait for the moment when the surface of hydrochloric acid will be without gas formation. At the bottom, the residues from zinc should stop releasing gases and only then can hydrochloric acid be used.