Winter lure can be done in a simple non-traditional way, unlike when the lure is soldered with a soldering iron. This method is good enough, but it requires some skill and ability to handle a soldering iron. Small baubles to solder quite conveniently. But with large things are much more complicated, because they can be overheated, it is almost impossible to make several lures the same, the main thing is to find your own shape.

How to make a similar winter spinner - look at the video

For the manufacture of spinners we need:

- plastic container;

- a piece of brass;

- alabaster;

- drill;

- a candle;

- lighter;

- file;

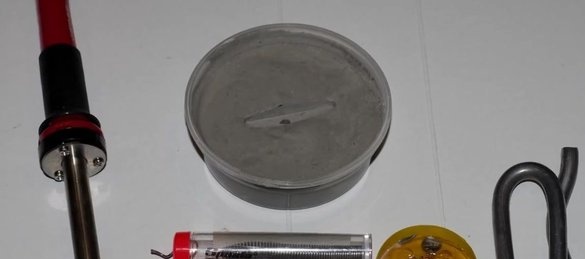

- soldering iron;

- sandpaper.

The spinner is about 4 cm long and weighs about 5 g.

The essence of the method is as follows. Make a reusable fill form for a particular spinner and just then cast all the spinners in it.

To do this, take a plastic container. As the manufacture of the casting mold, we will use alabaster, it quickly hardens and creates a fairly strong durable form.

Cut a plate of brass of the right size and bend it at the right angle along the workpiece. At the edges of the plate, small holes for the rings are immediately drilled.

After that, we make a tamper for the filling mold. This can be done only once at the very beginning. We light a candle and drip paraffin onto the plate. There is no need to rush, let each layer harden and only then drip the next. We process the tamper with a file, giving it the desired shape. We dilute the alabaster with water in a plastic container until a creamy consistency and temperament make an imprint in this pouring form.

When the alabaster is completely frozen, the tamper is removed with an awl or boiling water. A through hole is made in the mold, which is necessary for the convenience of removing the finished blanks from the mold.

It is necessary to tin a previously cut plate. We place it in the pouring form, prepare the desired amount of tin, about 5-6 g and melt it. Pour molten tin into the mold. It’s not worth pouring a lot of tin, because otherwise you will have to work more with a file.

When the tin has cooled down with a file, we bring the disc to the desired shape. We drill to the end of the hole, polish the entire plate with a sandpaper.

After that, the plate can be painted or decorative glitter can be glued with car varnish. After gluing the spangles, the surface is covered with several more layers of varnish in addition, with intermediate drying.

Winter baubles ready. Do not forget to polish the brass plate before each fishing trip.