What avid fishermen just do not come up with for successful fishing, as soon as they do not try to feed the fish in order to only get a good catch. But not everyone knows that you can use small feeder feeders, which are easily made in home conditions. Moreover, the material will not cost a lot of money, and by making feeders in batches, you will save a lot of your time. They will be very convenient for bait fish in water with a strong current.

How to make such a feeder, see more details on this video:

To create a feeder you need to cook:

- building mesh;

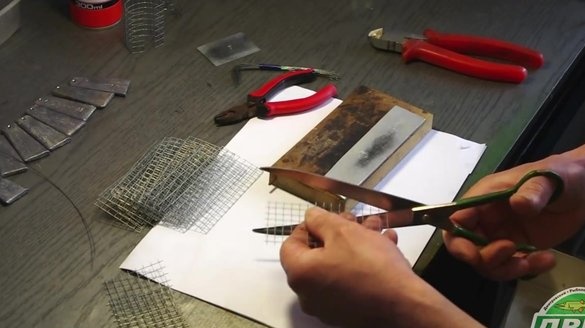

- scissors;

- pliers;

- soldering iron 65V;

- wire;

- nippers;

- sinker;

- file.

Building mesh must be taken with squares no more than 6 mm. From a large canvas we make small rectangular blanks (7 by 15 cells), which we will use further. And we try to trim them so that the edges are even, nothing sticks out.

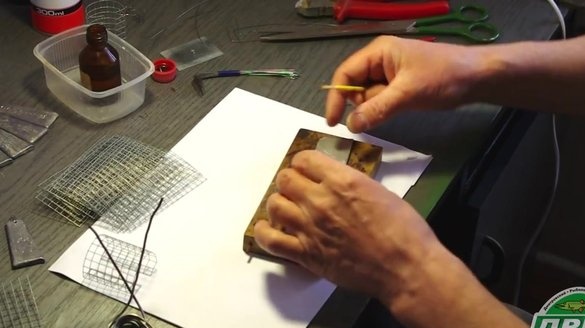

Each end of the workpiece must be bent 90 °, the size of the fold 2 cells. The part of the workpiece that was between the folds must be carefully bent into an arc.

Since the mesh is quite soft, the edges of the curved blank bend a little. This should not be. To eliminate the deflection, it is necessary to solder the shell along the edge (stiffener).

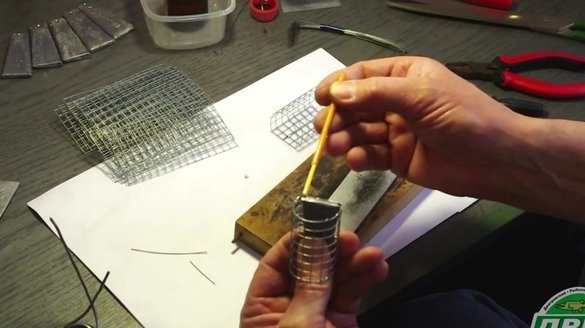

The shell is made of spring wire 62C. We cut it off about 100 mm and bend it in the same way as the contour to which it will be soldered.

For the sinker you will need a loop on which it will hold. We make an eyelet from a thinner wire. We bend its edges a little, bite off the excess so that nothing sticks out and we pass it through the hole in the sinker.

A sinker can also be made at home, taking a certain weight (about 50 g) of metal, which melts easily, and pouring it into a mold that is heated by gas.

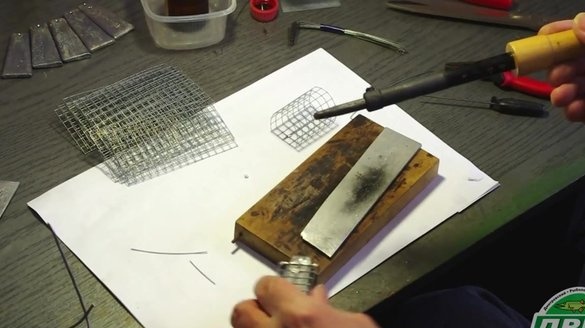

We solder the shells on both sides to the preform, preliminarily grabbing the edges of the preform itself. Also, the edges should be slightly cleaned with a file. We bite off the remaining tail with pliers.

We solder a loop on a sinker.

To solder the mesh to the sinker, it is necessary to clean the joints at the file, remove the oxide film.The sinker is soldered inside the net along the edges, to the flat part of the workpiece.

With pliers, slightly bend part of the sinker with a ring for ease of use.