Today we will look at some version of the Tesla Coil, called Browin Kacher. I will not go into history but I will say that the effect of quality (reactivity rocker) was discovered by a certain Brovin and patented the technology under his own name.

All welcome friends. I'll start my article with the word electricity. Electricity, as everyone knows, is fascinating; it can be both dangerous and useful. With electricity, you can move something; with electricity, you can light your way home. But today I will show how you can surprise with electricity.

Everyone has heard of the great genius Nicole Tesla and his Tesla Coil coils. At present, this device is gaining more attention than before. In appearance it is a complex device but in fact very simple. Today we will look at some version of the Tesla Coil, called Browin Kacher. I will not go into history but I will say that the effect of quality (reactivity rocker) was discovered by a certain Brovin and patented the technology under his own name.

But what is this kacher? Kacher is a high-frequency generator of high voltage, it means the swing of reactive power through the generation of a transistor (mosfet).

So, to make it and get such a beautiful effect ...

We will need: copper wire with a diameter of 0.1-0.3 mm, a copper busbar with a diameter of 2 to 5 mm, a pipe with a diameter of 2 to 7 cm and a length of up to 30 cm, a pipe of a larger diameter than the first, a mosfet (irfp460, iff840 and other similar ones), a pair of 1 kΩ resistors and 50 kOhm, dual Zener diode 1.5KE12 or similar, non-polar capacitor 400 volts 0.5-4 microfarads, diode or diode bridge for current up to 10 amperes and voltage 800 volts, inductor from LDS or primary winding of the transformer (participates as a current limiter, the power must be at least 50 watts), a radiator for a mosfet with an area of at least 50 squares

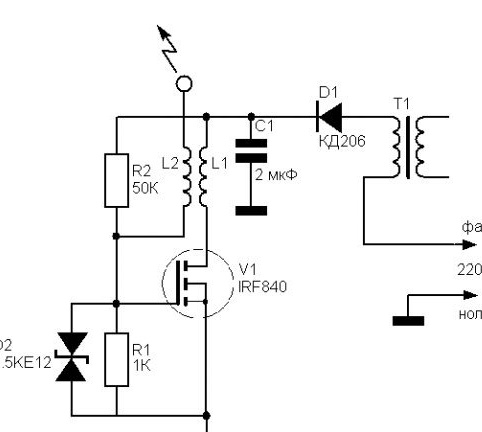

Here is such a sketch

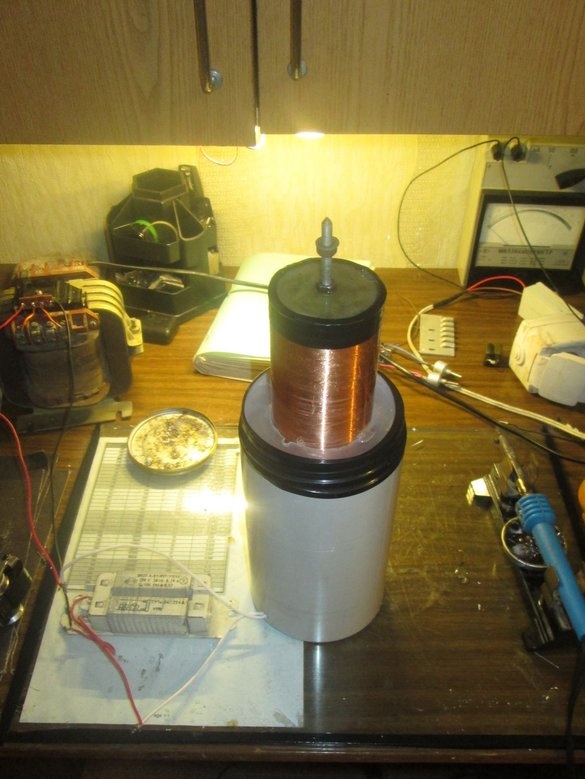

Everything needs to be prepared before assembly: the primary winding is wound in 1 layer with a thin wire onto a pipe of small diameter (800-1500 turns), after which it is impregnated with epoxy glue or other similar. The secondary winding is wound with a tire on a pipe of a larger diameter (5-9 turns) after which it is fixed with hot-melt adhesive or other similar.

After these manipulations, you are ready to build

Everything is going exactly according to the scheme (who does not know how to solder, learn, it will be necessary). When you finish soldering, it's time to check the device.This is done like this, add a 60-watt incandescent bulb to the circuit successively (if the circuit closes somewhere, the bulb will light up and nothing else will happen). If nothing works while the light is dim, this does not mean the assembly is incorrect, just swap the terminals of the primary winding and that’s it.

At the first improper start with the wrong scheme, expect: a loud babakh (the mosfet will burst), a lamp burning in full heat, the appearance of smoke or a burning smell. With the correct start-up and working scheme, expect: sparks will appear on the terminal (end of the secondary winding), the light will glow but not so brightly, the mosfet will confidently warm itself on the radiator (it should be so). After checking for operability, the bulb can be removed.

When all the tests have been successful, then it's time to think about the case, since without the case this rubbish that you have in the workplace will not look very kosher.

I use a pipe for the case, you can use the case from the computer’s power supply, everything is limited by your imagination.

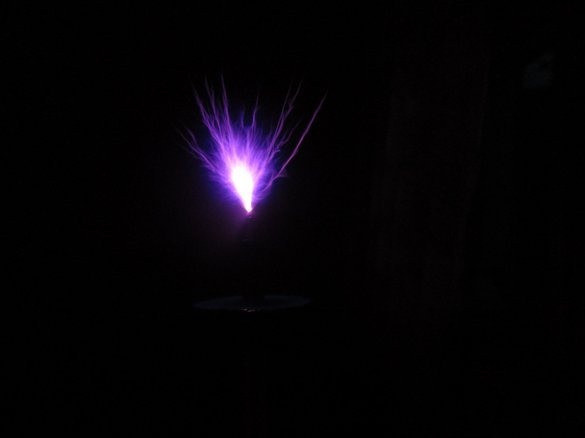

To complete the article, I will offer some beautiful photos of the received categories.