Papier-mâché material is a paper and cardboard pulp processed by a special technology that ensures the strength of the starting material. Its strength is equal to the strength of hardwood. It lends itself perfectly to a wide variety of machining: it is sawn, planed, grinded in all directions, unlike wood, which splits along the layer.

Special quality crafts from papier-mâché lies in the fact that the body of the product, called the "body" in production, is very light and cast, as it were. no seams. This provides high mechanical strength.

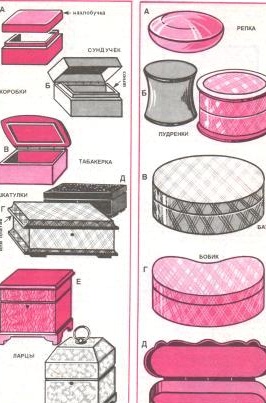

According to the type of enclosures, the products are divided into two main groups: rectangular, i.e. “Rigid” (Fig. 1), and round, oval (with rounded edges), i.e. “Soft” (Fig. 2).

In turn, rectangular “rigid” cases are divided into boxes (Fig. 1, a, b, c), caskets (Fig. 1, d, e), caskets (Fig. 1, f, g). Round types of cases have their traditional names: “turnip”, “powder”, “baul”, “bobby”, “pencil case” (Fig. 2).

If the body shape is rectangular, with clear flat faces, then the blanking test is performed by simultaneous crimping in two directions. This is done in a corner press or using two clamps. Figure 3 shows a diagram of the crimping of a workpiece in a corner press, consisting of a frame entering it on the sides of two screws, which, through the cheeks of the mortgages and overheads, compress the workpiece (bobbin with a winding).

Soft rounded shapes are crimped with a tourniquet or rubber band, tightly fitting the workpiece.

Another feature of papier-mâché technology is that almost all technological steps are long-term, requiring more time for drying and aging workpieces. The longer these processes continue, the better the quality of the product. It is better if the work has a constant rhythm. You can make one box, but still the technology itself requires at least a small but a series of things.

Stages of making a casket:

- The main types of products

- Necessary equipment

- Materials for making papier-mâché

- Winding and gluing blanks of the body

- Pressure testing and drying

- Workpiece boiling

- Filing

- Hardware fittings

- Casket decarning