On the video: the first inclusion, the test showed that the bottom bottle needs to add rigidity, which is done.

Materials and tools:

1. Old working vacuum cleaner and two hoses to it

Sewer PVC pipes D = 100mm, D = 40mm

Pipe sample

2. Thin sheet metal ~ 0.2-0.5mm or metal roof profile (must be straightened with a hammer)

3. Two plastic bottles of 2.5 liters with corks, 5 liter eggplant.

4. Scissors for metal, el. drill, drill, paper scissors, knife, PVC tape, hot melt gun, rivet and rivets

5. Welding electrodes or similar rods 6 pieces, adhesive tape wide, pencil

Appointment:

The Cyclone filter is designed for rough cleaning of the intake air; it removes heavy fractions before air enters the impeller of the pump turbine. Due to this, it is possible to suck in large enough debris, chips, wood chips and it will not damage or clog the impeller of the pump when using a vacuum cleaner without a bag or bag.

Application:

For collecting chips from the working area of the machine, drill, electric plane, saw, etc.

An example of the application of this homemade cyclone Works with CNC router

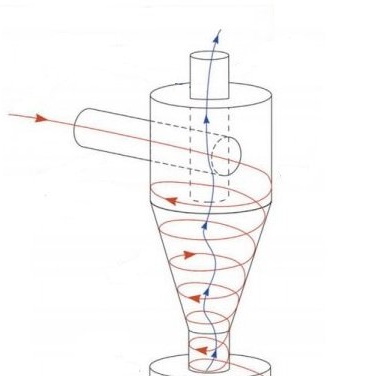

The principle of operation of the cyclone is shown in the figure below.

The sucked-in air with garbage is twisted into a high-speed spiral vortex, large particles are pressed by centrifugal force against the pipe wall, and spiral collect into the bottle under their own weight.

Manufacture:[/ u]

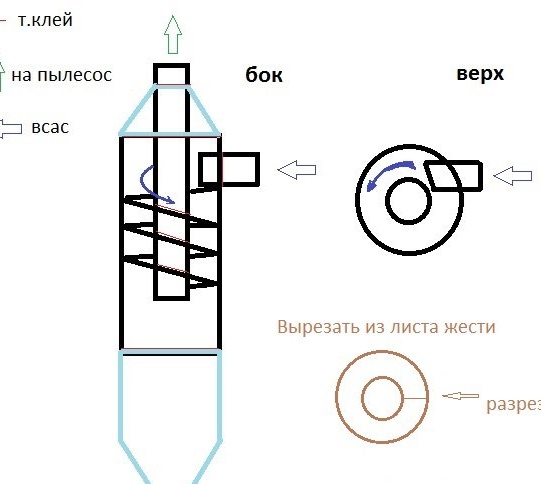

We cut off pipes with a diameter of 100 mm from PVC. straight segment 400-500 mm. , smooth, without mounting fittings, this will be the cyclone body.

Cut off from a pipe with a diameter of 40 mm. 100 mm cut. shorter than the body (this is the exit to the vacuum cleaner) and a length of 150 mm. (suction for garbage). On sheet metal, we draw three identical circles, with a diameter equal to the inner diameter of the casing pipe, it is convenient to circle directly through the pipe with a pencil, draw circles in the center of these circles equal to the outer diameter of the thin pipe, circle the pipe with a pencil.

[u] Scheme

Cut the circles with scissors for metal, then cut the circles to the middle, as in the diagram, cut out the inner circles. We connect the obtained circles with rivets in a single spiral. We put it on a thin pipe, distribute the coils evenly and additionally glue it all with hot glue from the gun.

Now we put the neatly obtained spiral construction into the body, if necessary, cut the hooks, leave the protrusion outward as in the diagram.

In the upper part of the pipe of the housing, we drill a hole for the pipe (suction), use the right knife to get the correct oval, for tight fastening of the pipe.

We insert the pipe and direct it as on the diagram, tangentially, we glue everything well from the gun.

We cut out the cap with scissors from a five-liter eggplant, remove the threaded neck, adjust the hole for the tight fit of the D-40 mm pipe, put it on the body and glue it with hot glue at the top and bottom.

Cut off 2/3 of the bottle length by 2.5 liters and put it on the bottom of the case, glue it.

We make from two plugs, gluing them together, a home-made coupling, drill the middle. The bottle, the garbage collector, must be reinforced with stiffening ribs, otherwise it will not withstand the vacuum of the vacuum cleaner and just squeezed, the ribs can be made of thin welding electrodes, after having beaten the coating with a hammer, and glued them with a corset around the circumference using a wide adhesive tape. We screw the bottle into place, attach the hoses of the vacuum cleaner to the inlet and outlet, they are ideally joined with PVC D-40 mm., Turn on and check the operation of the device.

P.S. If you use thinner hoses, for example PVC electric corrugation, then a strong whistle appears in these hoses, the cross section is not suitable for the performance of a vacuum cleaner.