Good day to all the residents of our sites.

It is known that music plays a big role for a person, it was on the basis of this thought that an attempt was made to assemble a sound amplifier that could produce decent sound.

So, for starters, we need patience, straight arms and curved gyrus, as well as tools and components for the amplifier. The chip itself can be purchased at the radio store. At the moment, it costs about 150 rubles. Actually, here she is.

You will also need a soldering iron with a capacity of about 30-40 watts.

Solder. A tin-lead alloy of 60% -40% is better.

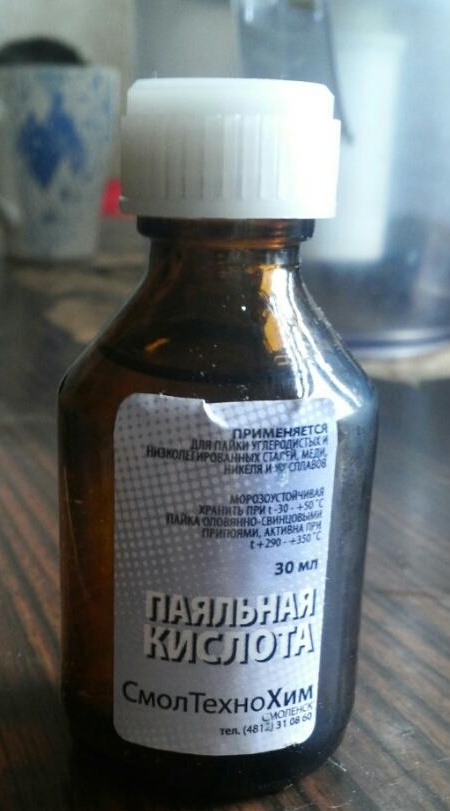

Soldering is best with soldering acid. The wires are immediately tinned without any

difficulties.

Amplifier assembly tweezers to hold the resistor and capacitor when soldering. They also need to bend the legs of the chip.

The sound input will be a 3.5 mm jack connector. Since the amplifier is two-channel, this plug is just right.

With thermal paste, the microcircuit will be better cooled, transferring heat to the entire surface. In this case, I used KPT-8.

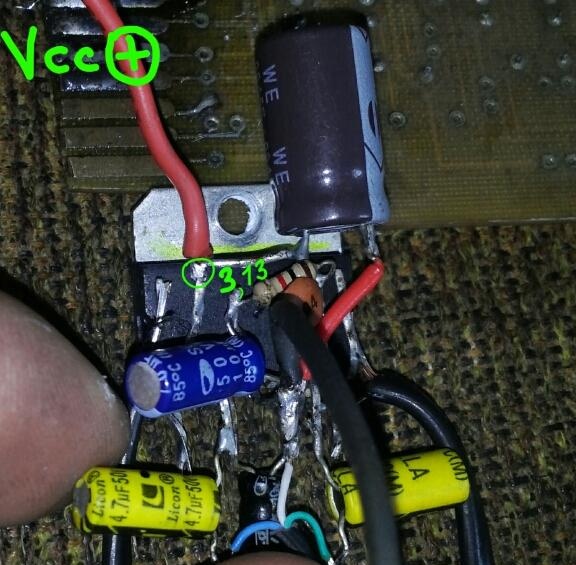

The amplifier will be mounted on this radiator. The bigger, the better. Since the circuit is quite hot, you will need capacitors, one resistor (all markings are visible in the photo), a resistor with a resistance of 10 kOhm.

To connect the sound will be a connector to two tulips.

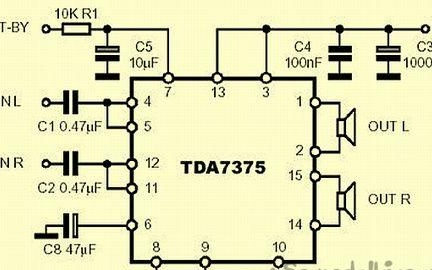

Well, all the components are ready, you can start assembling. The amplifier circuit was taken from the Internet. The amplifier has an output power of 35 watts for two outputs and a load of 4 ohms.

Assemble the amplifier can be mounted.

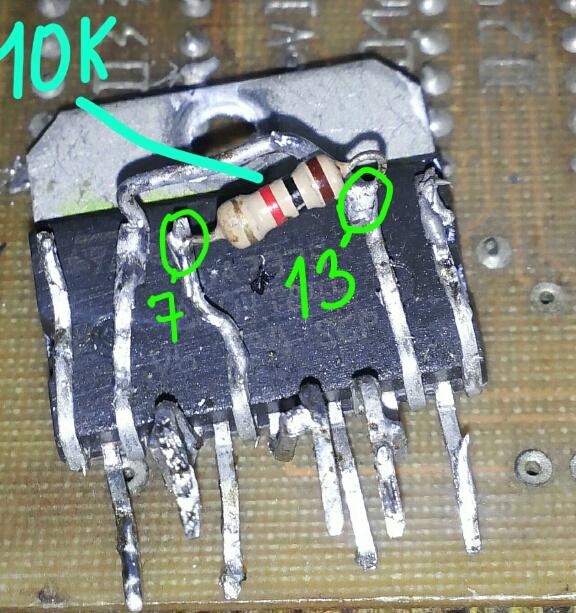

First of all, carefully unbend the legs of the microcircuit. For the convenience of soldering, we do it with tweezers.

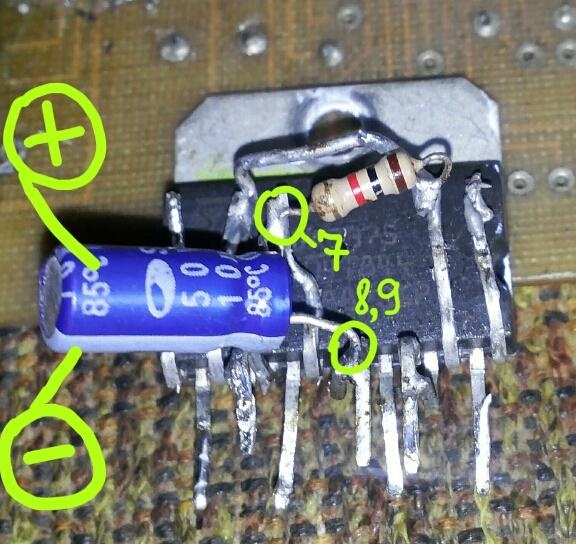

Then you need to solder 4 and 5, 9 and 8.11 and 12 legs of the microcircuit together.

3 and 13 legs are plus power, solder them with wire.

Between the 7th and 13th legs we solder a 10 kOhm resistor.

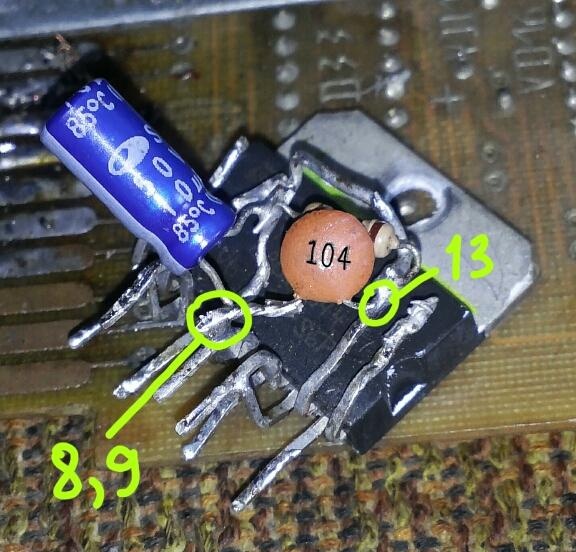

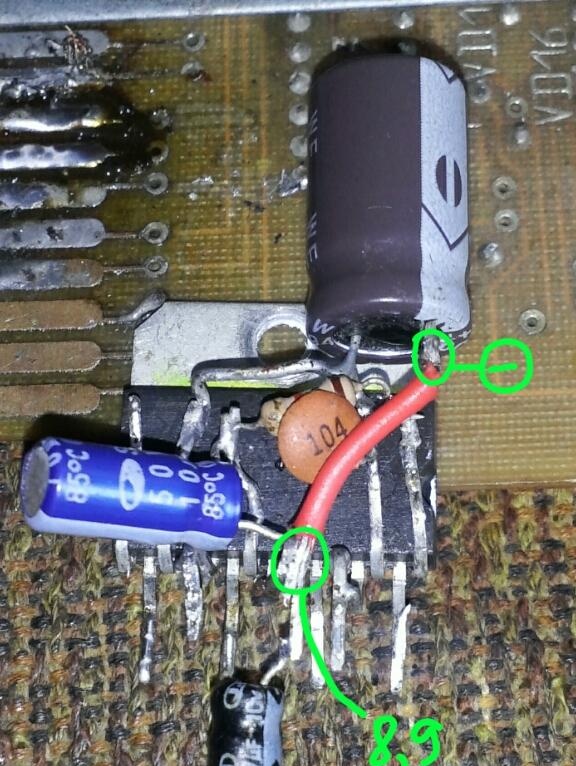

To the leg 7 plus solder the capacitor to 10 microfarads. Its other end is to 8.9 legs. To the 8.9th leg of the microcircuit, we put a dry capacitor with the marking 104, connected to the 13th leg.

To the 6th leg, a capacitor for 47 microfarads, connect its minus with 8 and 9 foot microns.

Now you need to put the power filter (this is a capacitor for 1000 microfarads), plus it is soldered to the 13th leg, and minus to 8 and 9.

The sound filters are 4.7 mF capacitors. Plus, each of the two goes to the 4th, 5th leg, the other capacitor to the 11th, 12th leg.

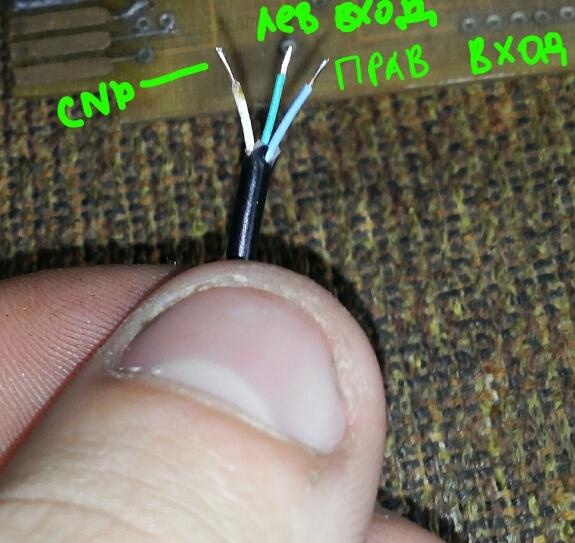

The next step: soldering the sound input (the plug itself). White is a minus, the other two wires are responsible for stereo mode, that is, the left and right inputs.Pre-tinning the wires, we solder to the conders.

Then it remains to solder the sound outputs, there are two, plus and minus power and arrange it all in a box. It is necessary to coat the back of the microcircuit with thermal grease with a thin layer and fix it to the radiator.

Now the final, cosmetic phase. We create the case, the basis was a black cardboard box.

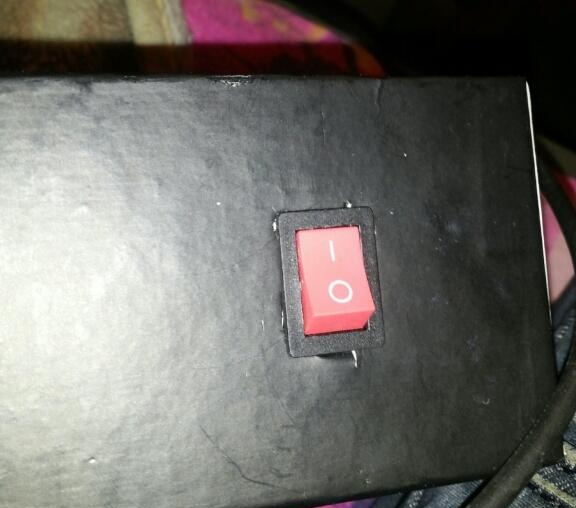

Cut a hole for the switch with a clerical knife on the front of the case.

On the reverse side, solder two wires to the lower contacts of the switch.

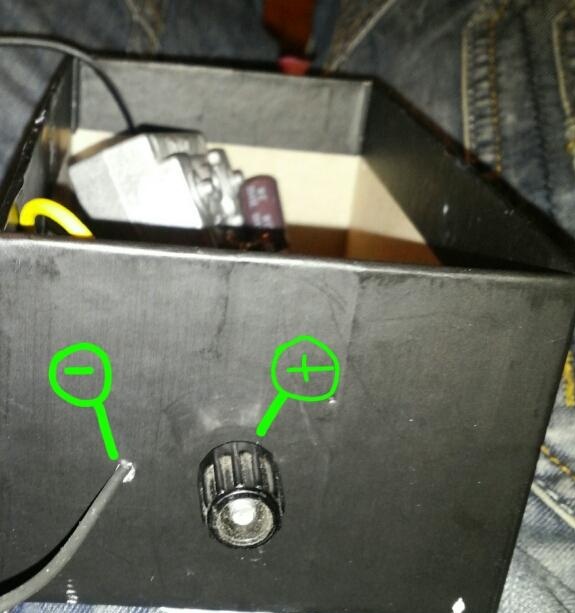

At the front of the case we have sound outputs for connecting tulips. On the reverse side we fix with hot glue.

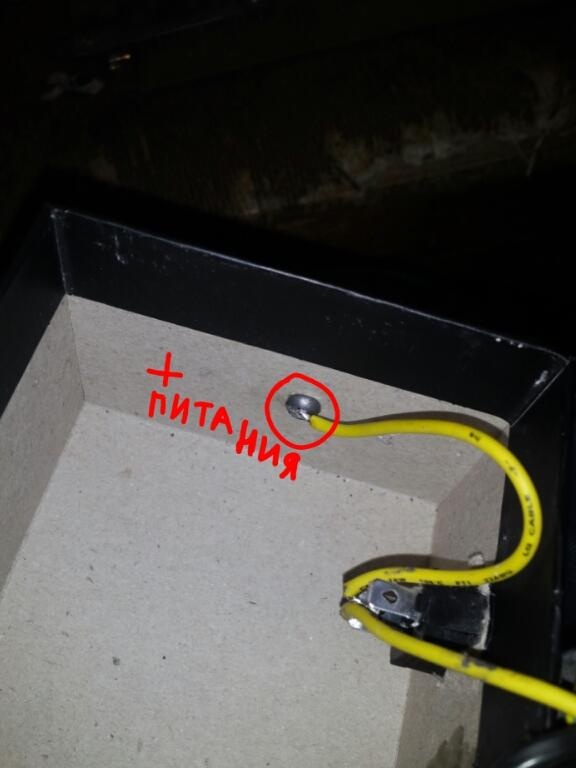

We take out a clip on the side for connecting the power plus and a black wire (ground).

On this, the amplifier is almost ready, it remains only to close everything on top with a lid, after having previously measured the dimensions. After the lid is fixed to hot melt adhesive.

Such an amplifier is suitable for home use, as well as in car.

The amplifier can be powered either from a computer power supply or from a car battery. Everyone enjoy listening to music.