A neighbor on the porch put up a washing machine-machine on the landing for further removal to the trash, as a specialist repairman told him, a kirdyk came to the motor. Not one, never in my life, will not pass by the thrown-out unit without taking it to spare parts or at least not looking inside the contents. I was the same sick, I decided to save my neighbor from hard physical work, taking the unit to the trash and took it for parts to my village.

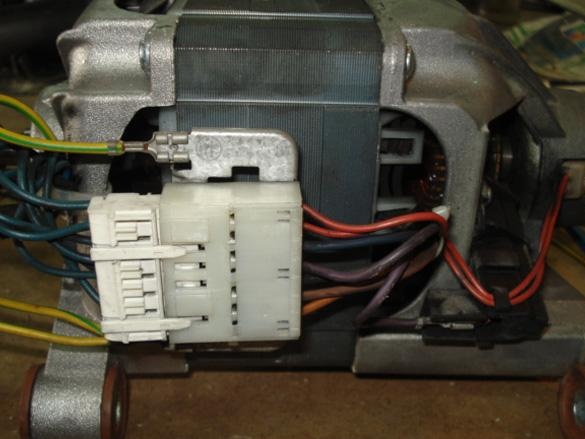

In the photo: One of the most useful elements of the insides of the washing machine.

Everything was sorted out into useful gadgets and it was time to check the condition of the motor.

Paragraph 1. Checking the motor.

To test the motor and upgrade the dimmer lighting, we need tools.

* Device (tester)

* Electric side cutters

*Dimmer

* Soldering iron

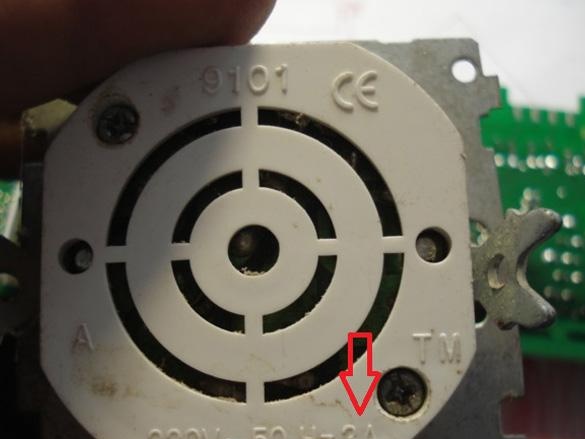

Inside was just such a universal collector motor MCA 52 \ 64 -148 \ KT11 390W. 13000 rpm

In the picture we see a seven-pin large connector, on the left are all the same blue wires (for the average person it’s more difficult to figure out) and one yellow-green (ground), on the right there are wires going directly into the motor, if you look from the top, then two red wires (on the travel sensor ), blue on the brush 1, purple on the other brush 2, black (the middle point of the motor windings), orange (two stator windings).

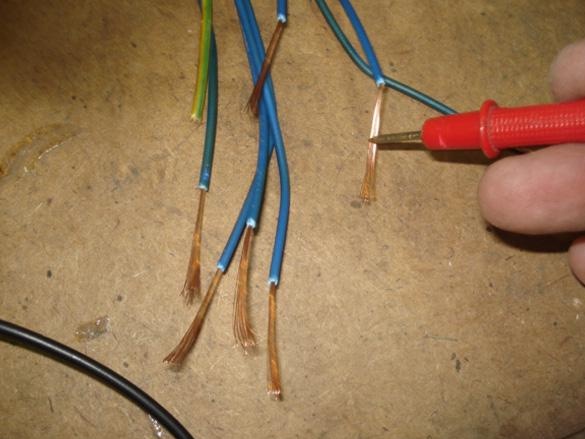

We strip all the blue wires coming out to ring them with a device.

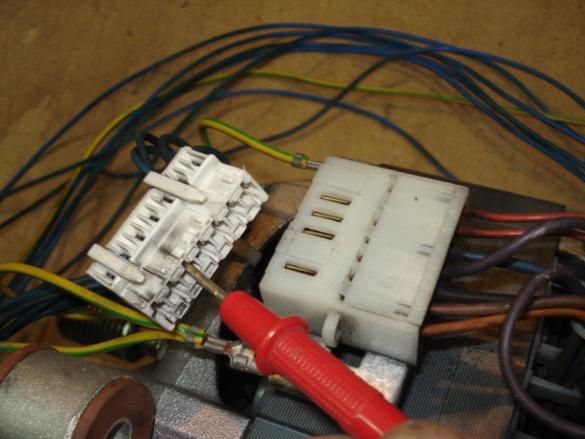

Disconnect the connector and call the tester which of the blue wires to which motor wire comes in, so as not to forget, you need to write down, sketch.

For a simple engine start, we need only two orange, blue and purple wires, the rest can be bitten off or insulated for future homemade products.

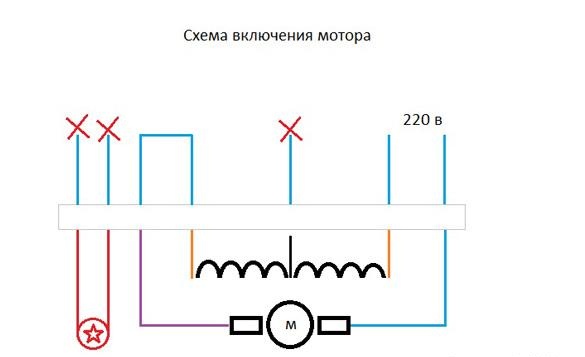

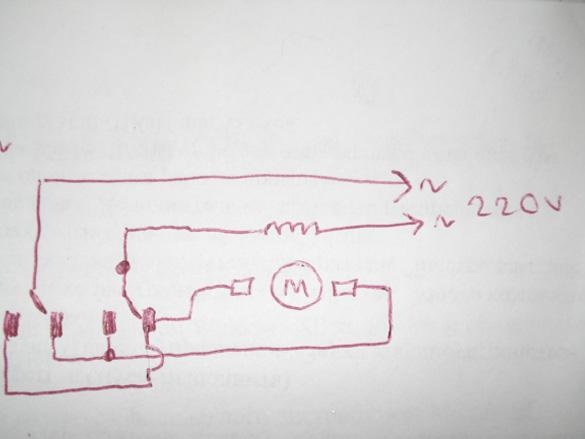

According to this scheme, you need to connect the motor.

You can check the operation of the motor, everything works (as in most cases it happens), only it is desirable to replace the bearings.

That's how repair specialists conduct diagnostics, the price of such a new motor is 6,000 rubles + installation work.

Point 2. Reverse.

This type of motor can be reversed, which is what the washing machine does during washing, for this it is necessary to change the brush attachment from one winding to another, only do this after a complete stop and de-energization of the motor.

Scheme. Reverse with the toggle switch.

Toggle switch itself.

Point 3. Speed control dimmer light.

It is also possible to regulate revolutions by reducing - increasing current, for example, using a wire rheostat of the required power or using a triac with a PWM controller.

As the simplest and most affordable, this is a dimmer for lighting (photo below), only be sure to look at what maximum current the regulator is rated before the first connection, we need a tenfold overlap of the rated motor power, because the starting current from our motor jumps from 8-10A and higher, even without load.

The cheapest dimmer.

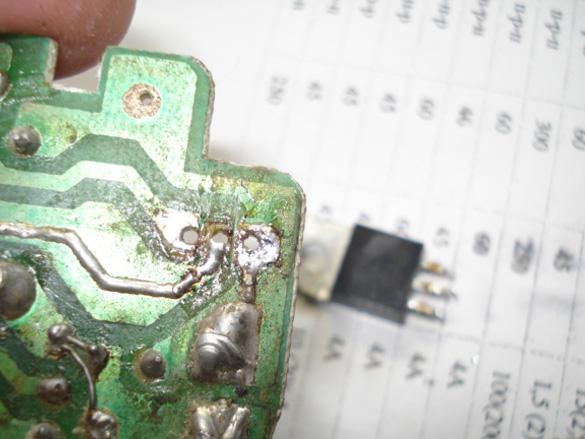

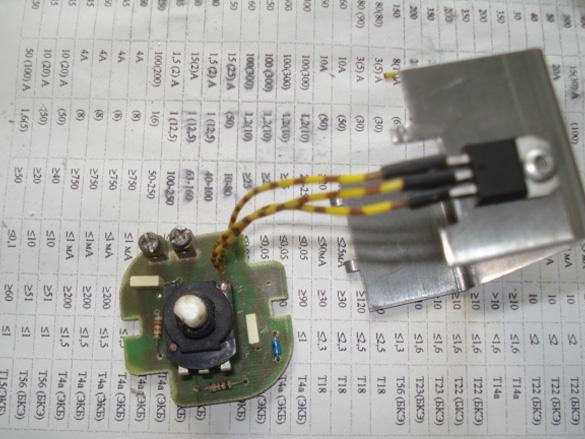

If the Dimmer turned out to be 3A like mine, then it can be finalized by finding the necessary triac right on the control board of the washing machine itself, where all the parameters are just calculated for this motor.

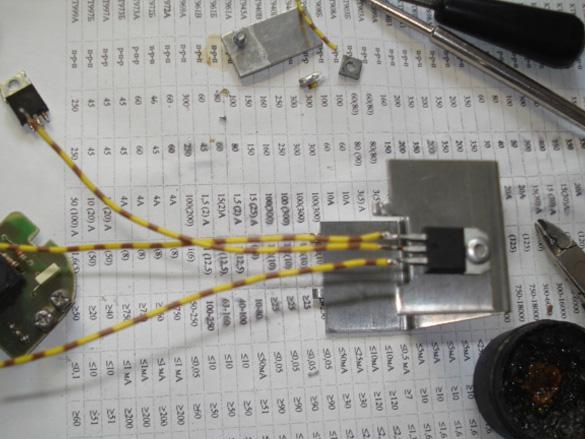

To do this, we will trace the path from the connection point of the motor terminal to the board and along the widest paths, one of which will definitely fit on one of the legs of the part we need (in my case, this is a BTB16 triac with three legs).

We disconnect the radiator mount and solder the part trying not to overheat.

The soldered triac along with the radiator is soldered to replace the old part in the regulator, now you can safely connect a load of 10 A and even up to 16A at the time of start-up.

We connect the regulator (Dimmer) to the gap of one motor power wire, turn it on and turn the knob of the regulator, the motor should start rotating, and the speed should correspond to the position of the regulator knob.

If, when connected to the network, the motor is in any of the positions of the regulator or is constantly working without changing speed, then the part (triac) turned out to be broken (burned out), provided that the regulator itself was initially operational.

Now we need to make a new building for Dimmer, the old one has become small for him. But that's another story.