Today we will assemble a simple pulse soldering iron

Let's watch the video:

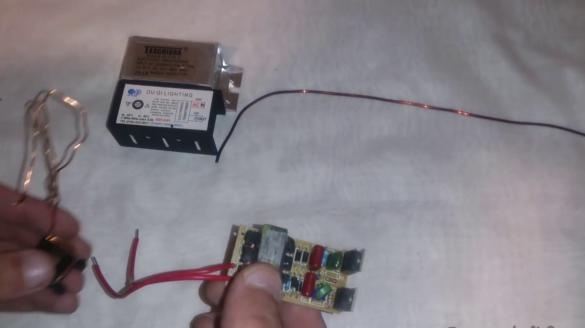

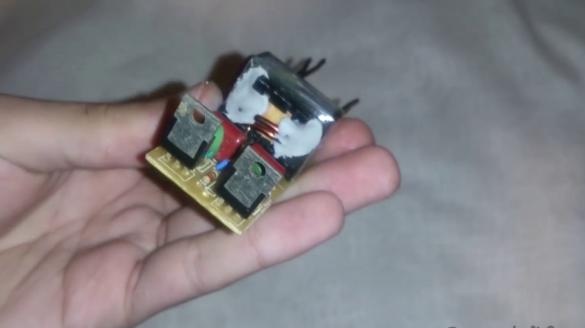

To work on, you need a few simple things, in particular this is a power supply, in the form of a Chinese TASCHIBRA transformer or similar

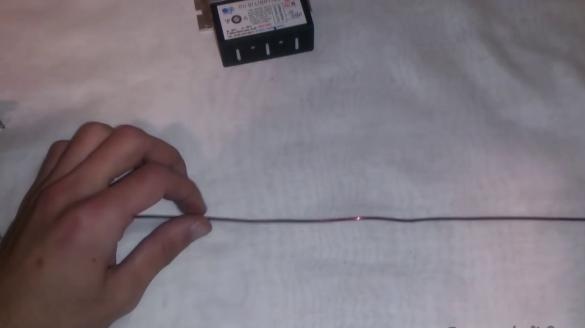

A piece of copper wire, preferably 30-40 cm long

When disassembling the transformer, we observe such a picture

On the right is the master part, and on the left is a pulse transformer, on which there is a primary and secondary winding.

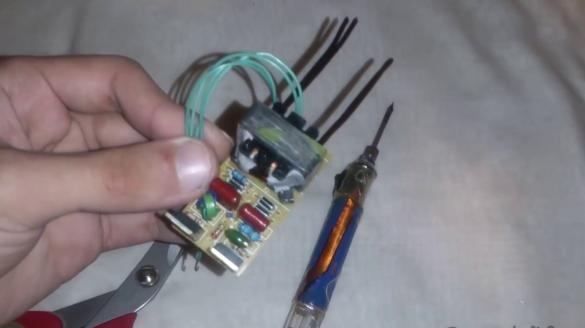

We leave the primary winding, and we need to completely remove the secondary.

We wind our winding, it consists of one incomplete turn with our wire. In order to raise the output current, preferably two parallel buses and thus twist onto the frame

Install the transformer with a new winding in place

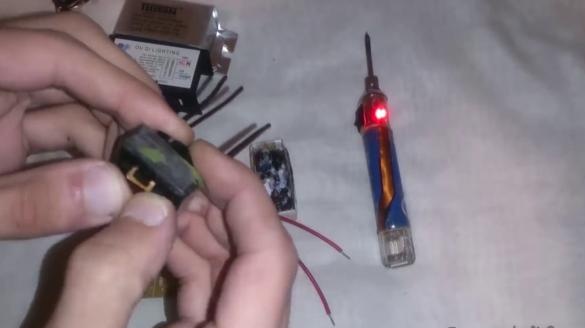

Now we need to somehow fix the winding on the transformer, for this we use cold welding

While the workpiece dries, let's take care of other components:

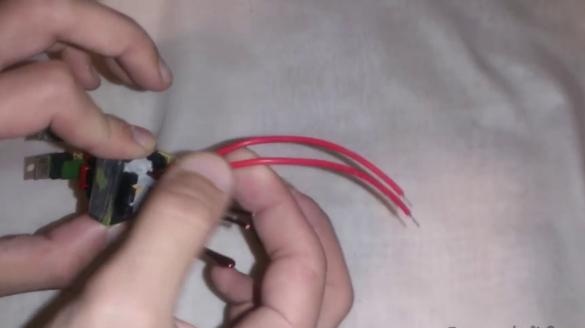

First is the power cord

At the expense of wires, I will replace them with a more elastic

Next we need a handle, with a through hole for the power cord

Now replace the wires and continue

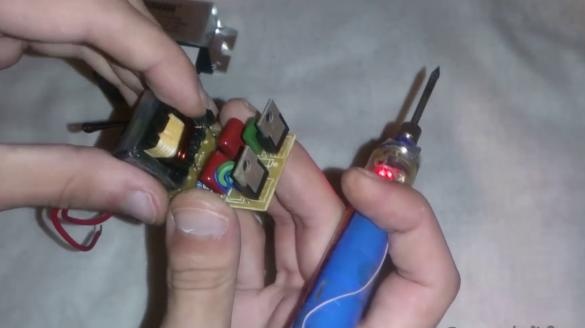

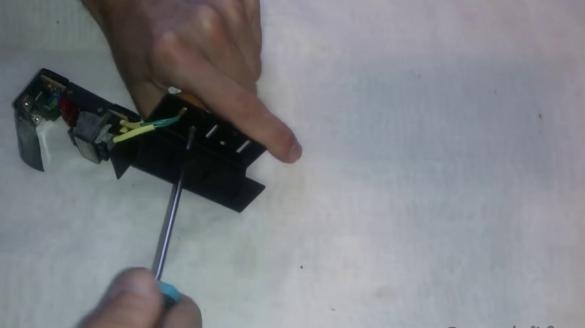

We begin to assemble our soldering iron, install it in the case

Set the switch

We continue to collect it longer, connect the power cord, with the switch and with the soldering iron itself

We fix the transformer cover

The next step will be making the sting itself

In order to attach the tip to the soldering iron, we use the connection for wires

Attach them

To make the sting itself, we need a copper wire, 1 mm in diameter, we give it the desired shape

Fasten it

And that's all, we just made a pulsed soldering iron do it yourself!