In my free time (which, by the way, like everyone else, is not very much) I am engaged in the manufacture of hunting knives. Not in series, not for sale, but for myself, sometimes for my friends - hunters. At the same time, you have to be content with a small amount of available hand-held power tools and a household grinding machine. In the manufacture of the latter product, he was puzzled by the problem of accurate (at a certain angle) and accurate sharpening of the cutting edge of the knife, on which, in fact, to a large extent, its cutting properties depend.

For sharpening a knife of my production fixtures industrial production is not suitable, as they are designed to form the cutting edge of knives with slopes starting less than the middle of the width of the blade. In my case, the blade in the cross section along the entire length has a triangular shape, which does not allow it to be clamped securely in similar devices with parallel “jaws”.

I had to design a device for forming and sharpening the cutting edge with a fundamentally different device for the rigid fixation of the knife.

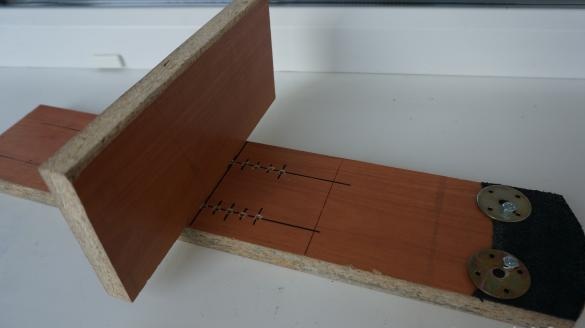

The device for sharpening the cutting edge that I designed consists of three main elements: the base, on which the magnet from the HDD is fixed, and two eccentrics, an emphasis and a rod with a bar. The magnet and eccentrics firmly in the set position hold the blade of the knife, while allowing it to work on it with a bar. A bar mounted on a bar lying on the stop forms the edge of the cutting edge of the knife at a certain angle (35 - 40 degrees)

Materials and tools:

- a small piece of furniture chipboard;

- a metal tube (in a previous life, a handle from a factory mop);

- Russian-made bilateral diamond bar for sharpening knives;

- a small piece of leather (from an old boot);

- electrical tape;

- two bolts with nuts;

- two metal washers;

- several screws;

–Magnet from an old (faulty) hard disk drive.

- hacksaw for wood;

- a hacksaw for metal;

- grinding machine;

- electric drill;

- screwdriver;

- manual frezer.

Description of manufacture:

Step 1: Create the base of the device.

From the chipboard trim, we cut out the rectangular base, 100 x 450 mm in size. Round one smaller side. On the contour of the magnet removed from the old hard magnetic disk using a hand milling cutter, select a recess of 6 mm. We mark and drill two holes for eccentrics and 8 - 10 pair of holes for fixing the stop.

Step 2: Create an emphasis.

From the same chipboard trim, we cut out a rectangular emphasis measuring 220 x 100 mm

Step 3: Mount the knife securing device

We fix the magnet with two screws in the recess cut out at the base.

We mark and cut out the leather substrate, cut out holes for eccentric bolts in it.

We glue the leather backing to the base, after inserting the bolts into the holes.

We drill holes in metal washers, the eccentrics thus obtained are fastened to the base with bolts and nuts.

Step 4: We assemble the base with emphasis.

Empirically, we select the distance from the edge of the device for fixing the knife, to the stop, so that the sharpening angle is the necessary 35 - 40 degrees. Using two self-tapping screws we attach the stop to the base through the corresponding pair of holes. Subsequently, the angle of sharpening can be changed by moving away or bringing the emphasis closer to the edge of the knife.

Step 5: Attach the sharpening bar to the bar

We cut a piece of tube with a length of 600 mm. At a distance of 150 mm from the edge using a hacksaw and a sharpening machine we make a cut 5 mm deep

We wrap the cutout with electrical tape. In the resulting recess, place the bar and attach it with electrical tape. We get a bar on the bar. Since it is double-sided, if necessary, we attach it with the reverse side in the same way.

The sharpener is ready. We fix the knife blade on a leather substrate with a magnet in the required position. We make emphasis with the help of eccentrics. We form the cutting edge of the blade with a bar on the bar at the angle of sharpening of your choice.

I would be glad if someone takes advantage of my experience!